Product Introduction

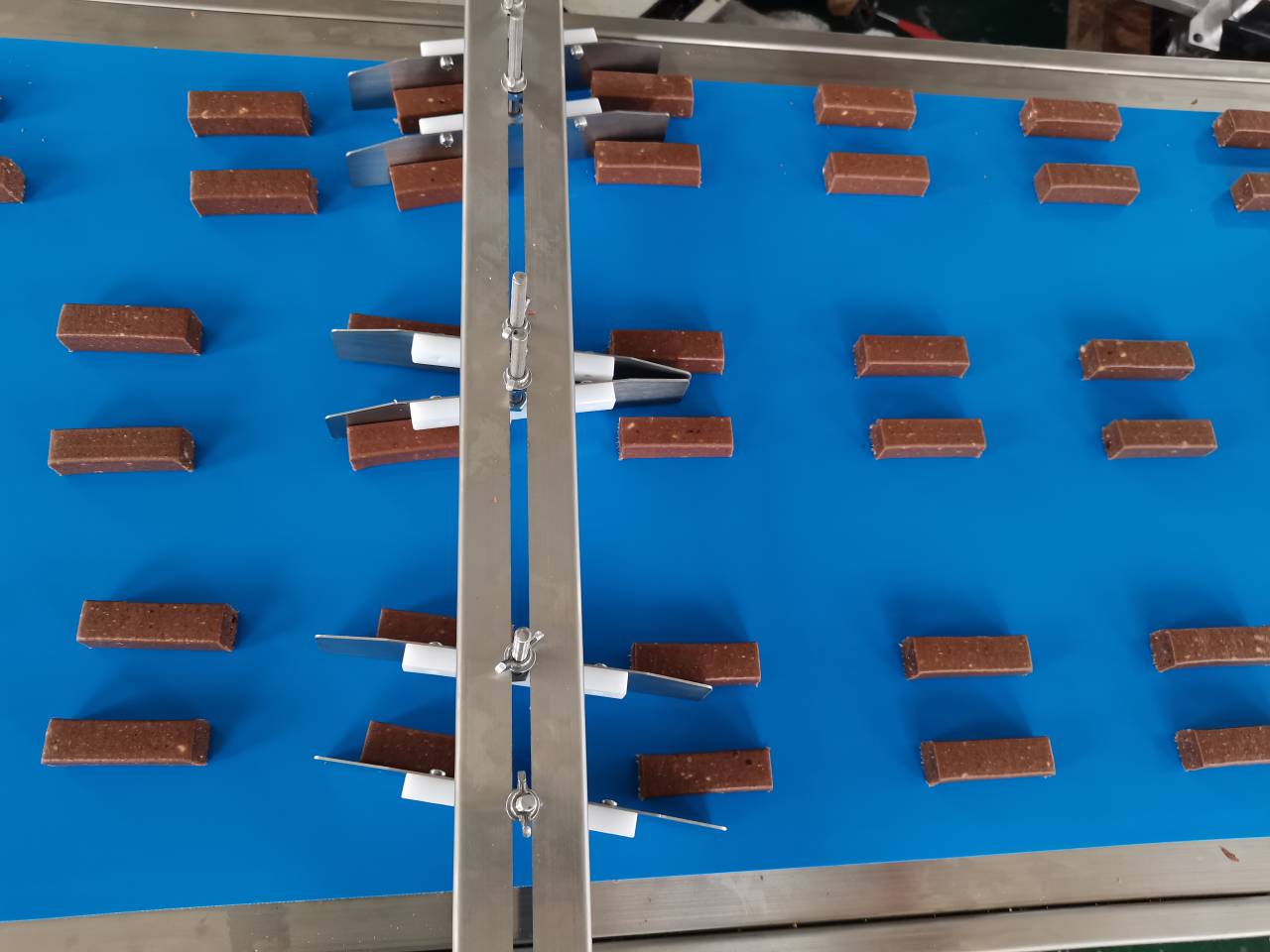

The P400 multi-row protein energy bar extruding machine is specifically created to meet the high productivity demands of clients seeking to produce soft or hard energy bar food. The upgraded P400 multiple lanes nutrition bar making machine can produce 150-360 pieces per minute. All the machine's metal components, including the extrusion screw, are constructed using durable and excellent 304 stainless steel material. The energy bar extrusion machine is controlled by a PLC program and operated through a touch panel, ensuring fast and stable operation. The touch screen allows for easy adjustment of settings, such as speed control for each section and memory settings.

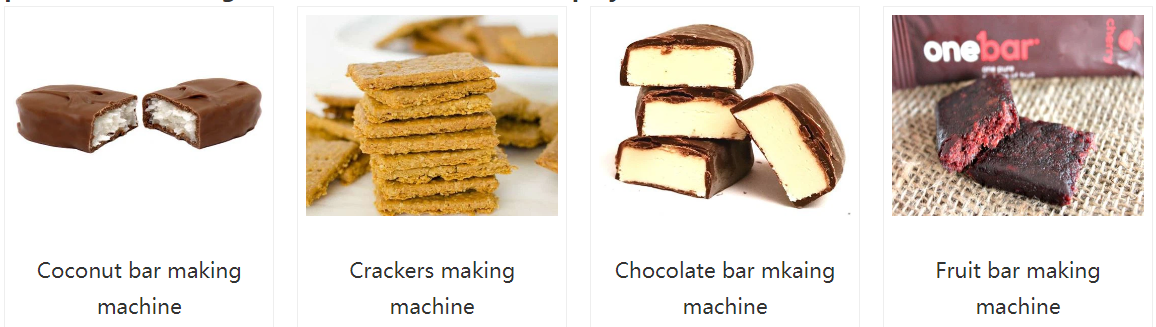

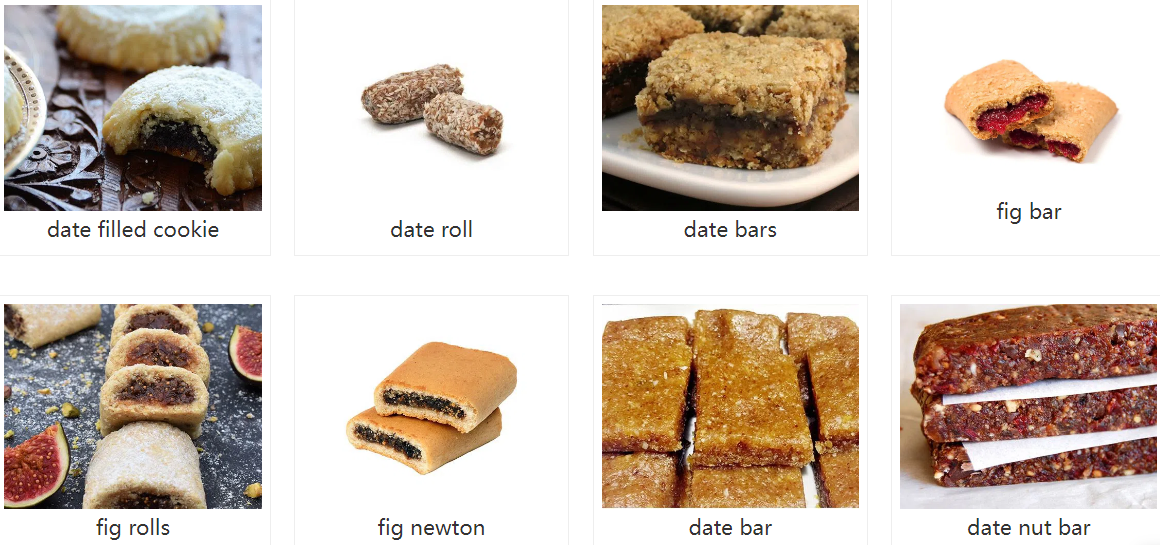

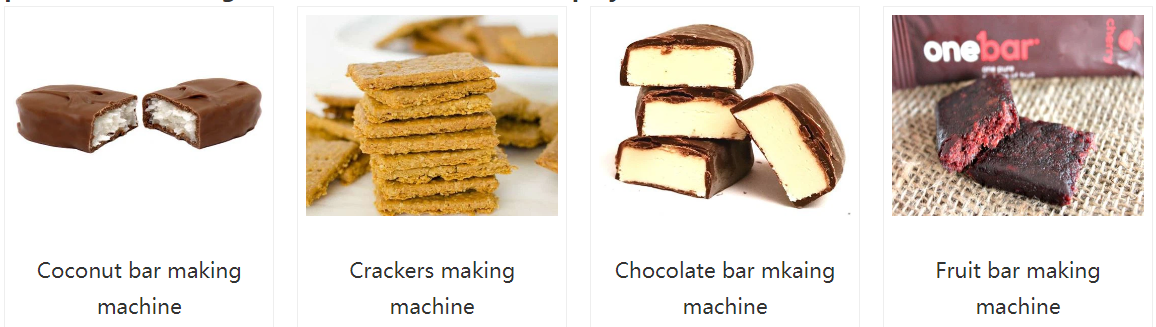

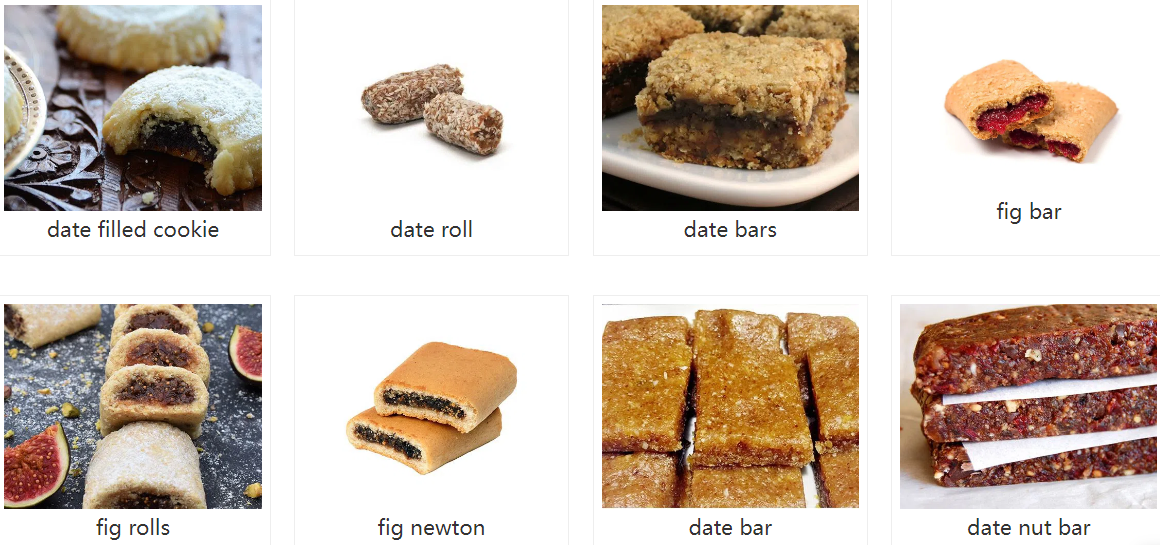

The P400 multi-row protein bar making machine is designed to accommodate various bar shapes, including bar shape, round shape, disc shape, bite shape, pyramid shape, and more. It can produce protein bars, date bars, fruit bars, energy bars, power bars, nutrition bars, coconut bars, biscuits, and other similar products, regardless of whether they are made from hard or soft mixes or dough.

Automatic encrusting and forming machine is mainly designed for customers who have high productivity requirements for soft or hard protein bar foods. Our newly upgraded P400 multi channel energy bar production machine has a productivity of 240-480 per minute.

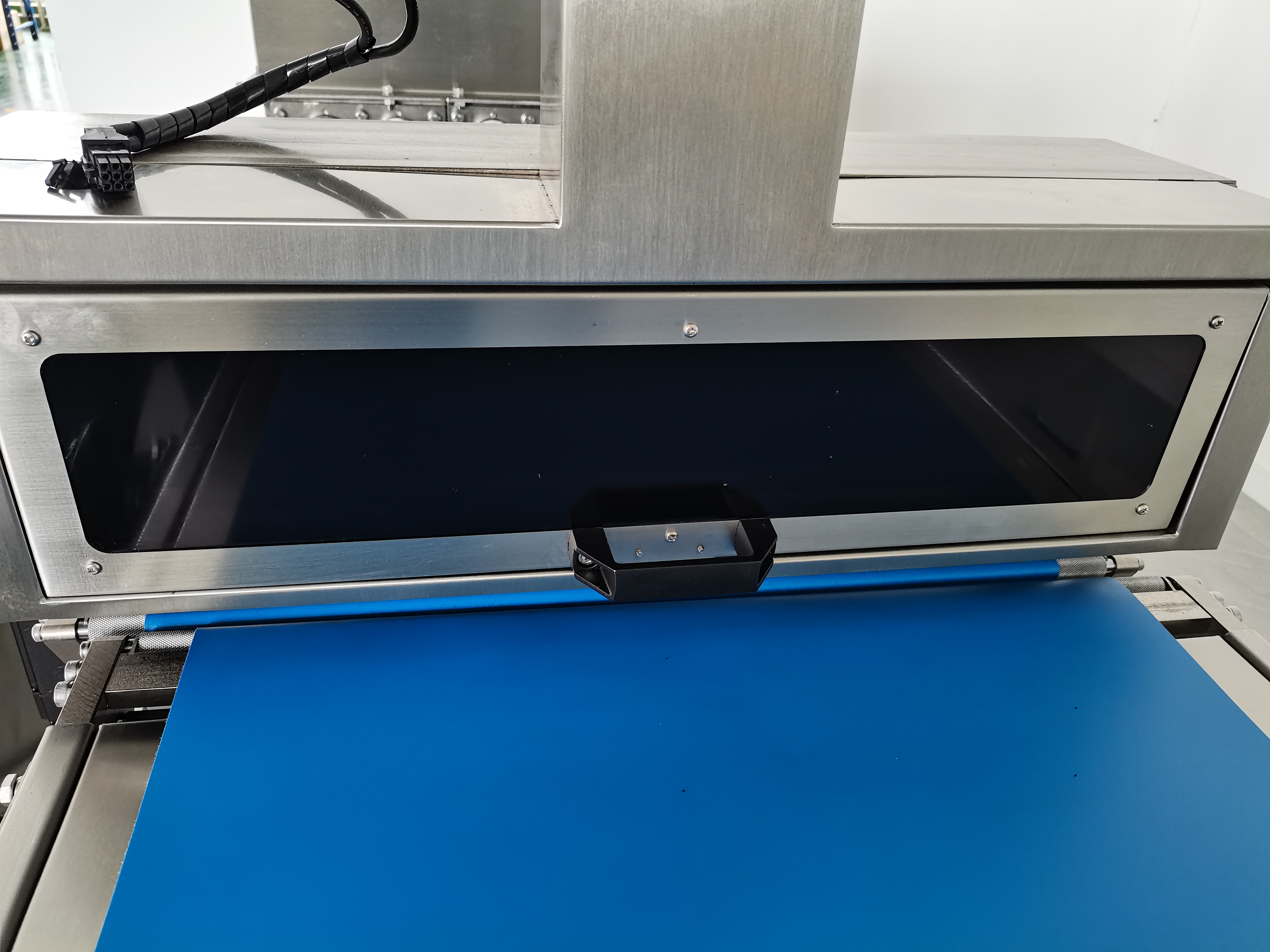

All metal components of the machine are made of durable and high-quality 304 stainless steel material, including extrusion screws. The energy bar extruder is controlled by a PLC program and a touch screen to ensure fast and stable machine operation. All settings are made on the touch screen, including speed adjustment and memory settings for each section. English operation systerm , you can set protein bar dough speed , cutter speed and so on ...

The P400 multirow protein bar extrusion and cutting machine is designed specifically for various rod shapes, such as rod, circular, disc, bite, pyramid, etc. It can be made into protein sticks, date sticks, fruit sticks, energy sticks, power sticks, crackers making , almond bar , chocolate bar , chocolate protein bar nutrition sticks, coconut sticks, biscuits, Chocolate Nut Protein Bar Peanut Butter bar ,Chocolate Peanut Butter Pie Keto Protein Bar etc., whether it is a hard or soft mixture or dough.

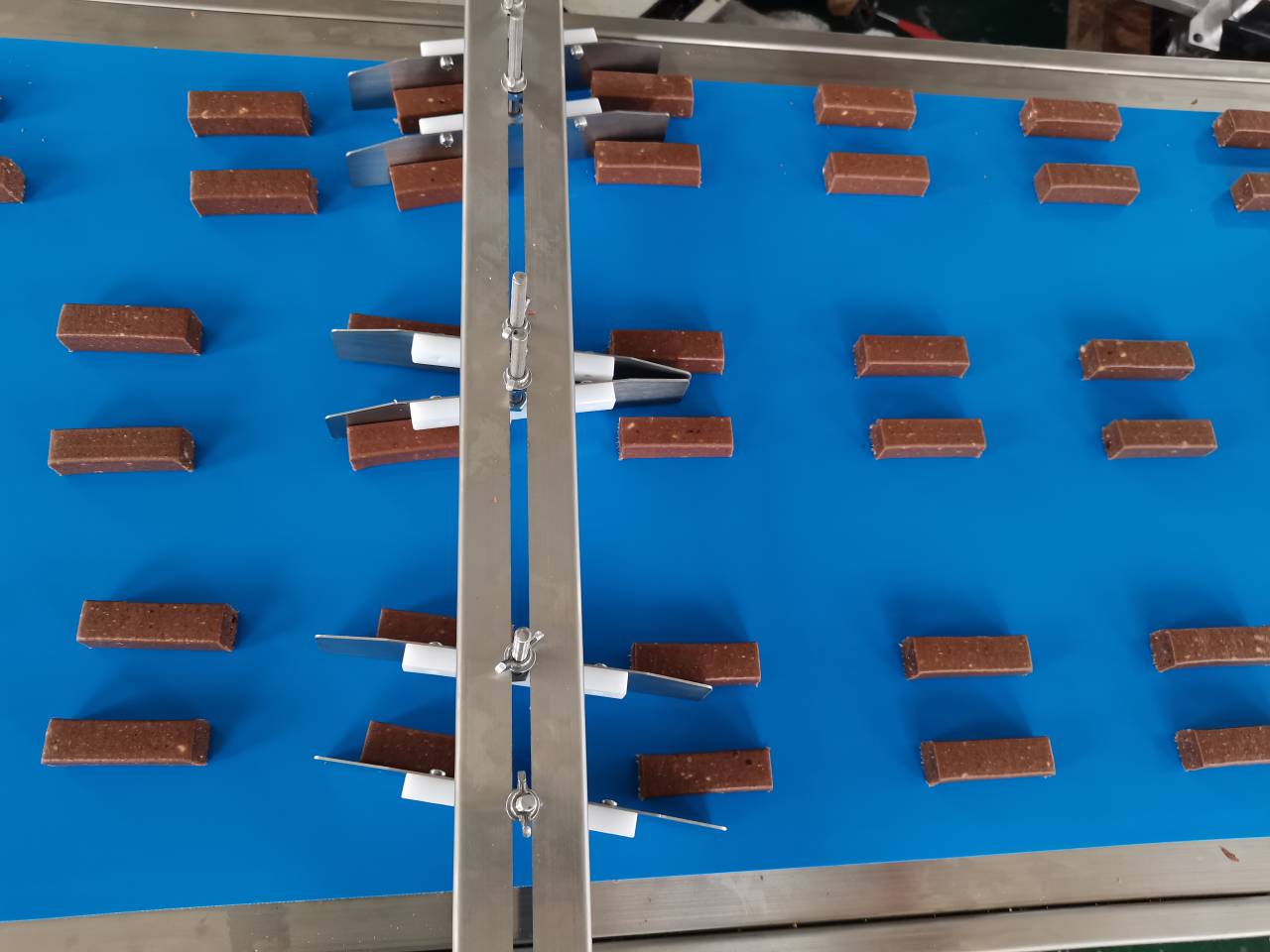

The conveyor belt can be customized made into 400mm , 600mm width . then will be match with chocolate coating enrober machine to making chocolate protein bars .

finished protein bar photos :

Multiple lanes protein bar production line for trapezoid shape bar machine video :

more Protein bite/energy bite video :

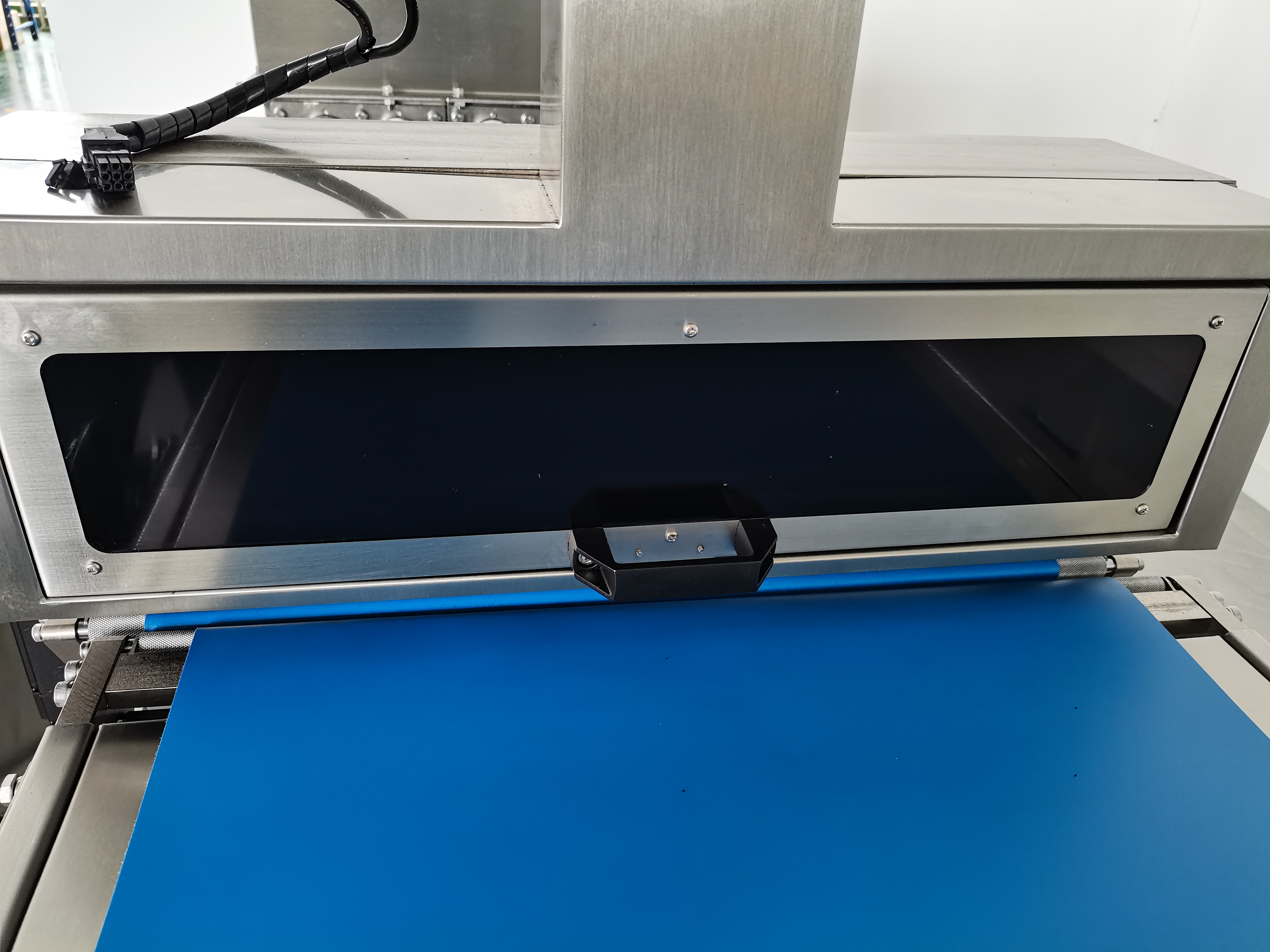

400/600mm Chocolate coating machine with cooling tunnel .

Chocolate Enrobing Enrober Machine With Factory Price for biscuit is to coat chocolate on various food such as cereal bars, energy bars, protein bars, candy bars, rice bites, wafers and wafer stick, birthday cakes, cakes, breads, rolls, pies, muffins, snacks, candies, confectionery, maamoul and mooncakes, cookies, biscuits, crackers, cake ball, date ball and chocolate truffles, mochi, dates for whole coating, single-sided coating, partial coating and cooling.

Features:

The machine can coat the whole surface or coat the single surface. The coating areas can be controlled by vibration and wind speed.

Fan speed is uniform ,high quality for coating the chocolate .Coating surface is uniform, smooth and beautiful.

The conveyor belt is provided with automatic correction device, the machine adopts touch screen, PLC control.

The cooling tunnel device is designed by us ,with air flow uniform and stability ,better than the normal equipments.

The machine is easy to clean ,the mesh uses pulling type ,it takes only about 20 minutes to clean the machine .

The machine can be designed for two double mesh belts to coat ,one side can be coated with white chocolate ,one black chocolate.

The length of the machine can be adjusted according to customer requirements.

Different models of chocolate enrobing line specifications:

| Model | 400 | 600 | 900 | 1200 |

| Belt width | 400mm | 600mm | 900mm | 1200mm |

| Belt speed | 1-10meter/min | 1-10meter/min | 1-10meter/min | 1-10meter/min |

| Cooling tunnel length | 10meter | 14meter | 20meter | 24meter |

| Refrigerator unit | 2 | 3 | 4 | 5 |

| Refrigerator | DANFOSS | DANFOSS | DANFOSS | DANFOSS |

| PLC/Touch screen | Hpmont | Hpmont | Hpmont | Hpmont |

| Voltage | 380V, Three phase | 380V, Three phase | 380V, Three phase | 380V, Three phase |

| Power | 12.1kw | 20.8kw | 23.8kw | 27.8kw |

| Dimension | 14200x950x1800mm | 18200x1150x1800 | 24200x1450x1800 | 28250x1750x1800 |

| Weight | 2000KG | 2450KG | 3400KG | 4100KG |

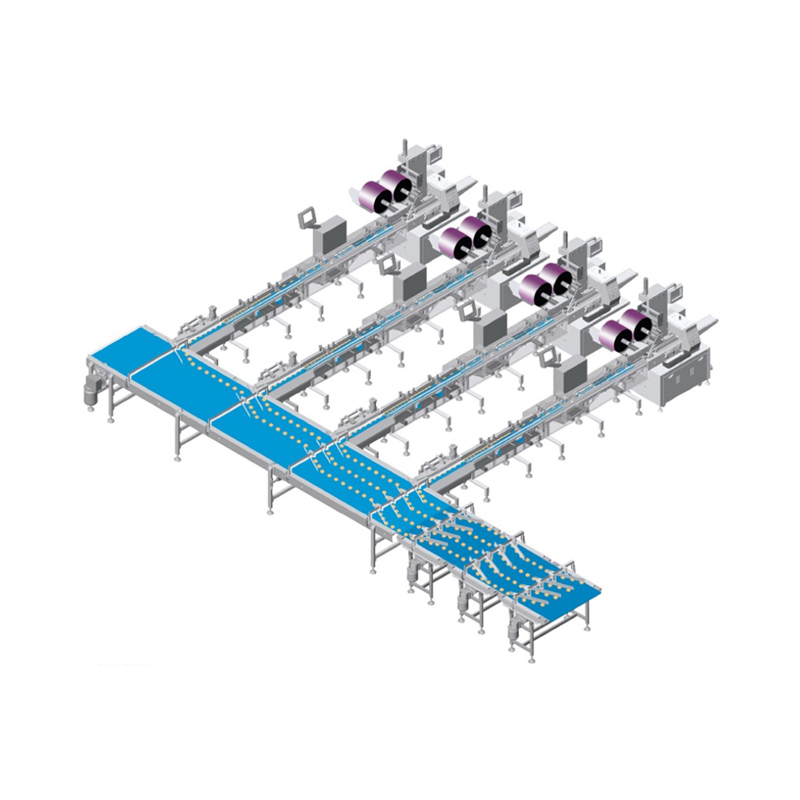

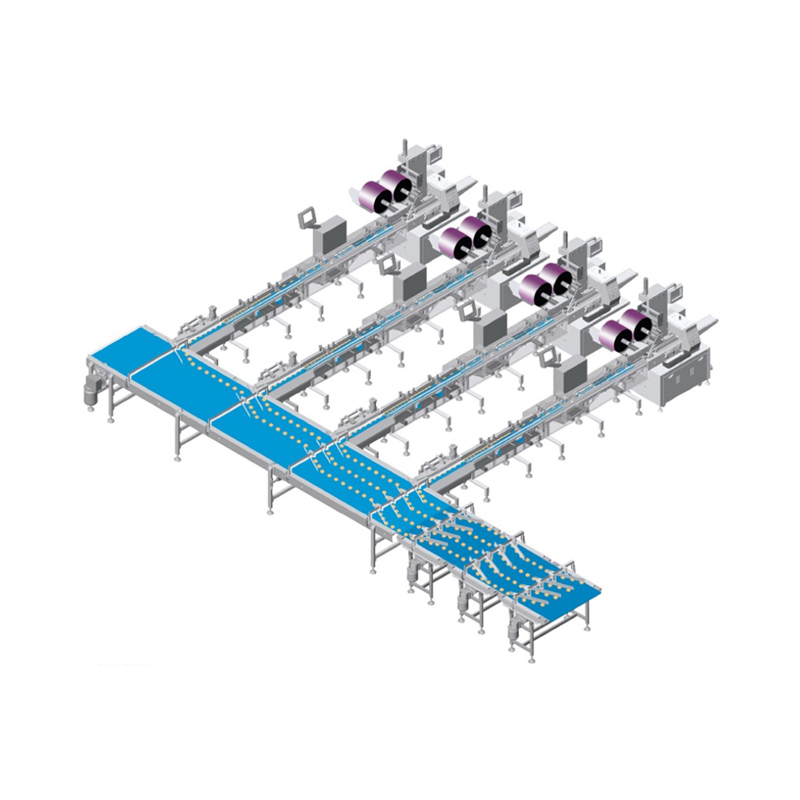

high capacity multirow protein bar date bar fruit bar making machine working with flow packing machine

The automatic flow packing syterm is used for aut bar sorting prefeeding and automatic packing .

it has the function of counting bar numbers , sorting bars , packing bars , no need workers ,it is fully automtaic systerm .. it largely saves the time and labor .

multirow protein bar machine work with packing machine .