Automatic Pita Bread Production Line / Puff Pastry Machine

EQUIPMENT INFORMATION

Description:

The Automatic Mini Burger Buns/Slider Buns/Mini Hamburger Buns/Hamburger Buns production line is a specialized set of machinery and equipment designed for the automated production of these specific types of bread products. It offers high efficiency and consistency in producing mini burger buns, slider buns, and hamburger buns on a large scale.

The production line consists of several key components that work together seamlessly:

Dough Mixing: This component involves a dough mixer that combines the necessary ingredients to create the dough for the burger buns. It ensures proper mixing and consistency.

Dough Divider: The dough divider takes the mixed dough and divides it into equal portions, creating individual portions for each bun. This ensures uniformity in size and weight.

Dough Rounder: The dough rounder takes the divided portions and shapes them into round balls, ready for further processing. It ensures smooth and consistent shaping of the dough.

Intermediate Proofer: The intermediate proofer provides a controlled environment for the dough to rest and rise. It allows the dough to ferment and develop flavor while maintaining the desired temperature and humidity.

Dough Moulder: The dough moulder takes the rounded balls of dough and rolls them into the desired shape for burger buns, ensuring a uniform thickness and size.

Proofer: The proofer provides the ideal conditions for the dough to undergo final proofing, allowing it to rise fully before baking. This step ensures proper texture and volume in the finished buns.

Oven: The oven is where the dough is baked to perfection, giving the burger buns their characteristic golden crust. It provides precise temperature control and even heat distribution for consistent baking results.

Cooling Conveyor: After baking, the burger buns move along a cooling conveyor, allowing them to cool down before packaging. This helps maintain their quality and texture.

Packaging: The production line may include a packaging component where the burger buns are automatically packaged and sealed for transportation and storage. This can involve various packaging options, such as bags or trays.

The Automatic Mini Burger Buns/Slider Buns/Mini Hamburger Buns/Hamburger Buns production line is designed to optimize efficiency, consistency, and quality in the large-scale production of these specific bread products, meeting the demands of commercial bakeries and food production facilities.

Standard bread production line:

Double lanes bread production line:

Specifications:

| Model | P886 |

| Capacity | 1800-20000 pieces/hour |

| Voltage | 220V, Single phase |

| Power | 7.2kw |

| Dimension | 6123*1500*1620mm |

| Weight | 1200KG |

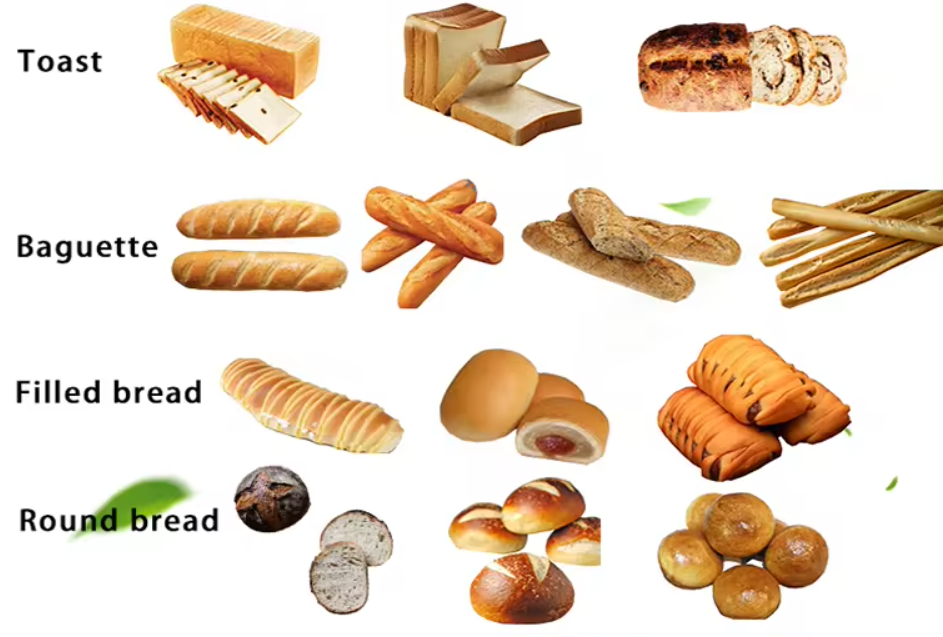

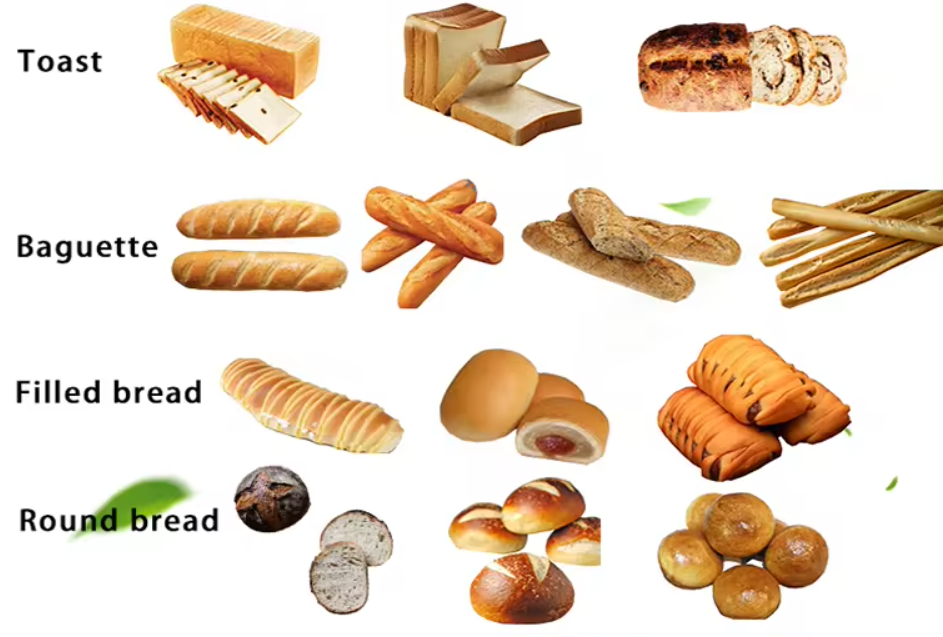

| Application | stuffed bread, toast bread,dinner roll, burger, crispy pastry, steamed buns, etc. |

.