Product Introduction

Multirow protein bar Multiple rows bar extruder

P400 Multiple protein bar machine is a cutting-edge equipment specially designed for the efficient and high-quality production of protein bars. It is equipped with advanced features and technologies to simplify the manufacturing process, allowing you to mass produce a variety of protein bars. One of the main advantages of the P400 machine is its versatility. It enables you to produce multiple types of protein bars at the same time, each with different ingredients and flavors. This not only saves time, but also gives you the flexibility to meet different client preferences. The P400 machine has a user-friendly interface and can be easily operated and adjusted to your specific requirements. It allows precise control of every aspect of the production process, such as dosing, mixing, shaping and cooling. Additionally, the machine was designed with efficiency in mind. It optimizes energy consumption and minimizes waste, ensuring cost-effective and sustainable protein bar production. Durability and reliability are also core features of the P400 machines.

It features high-quality components and materials designed to withstand rigorous and constant use, guaranteeing long-lasting performance. Whether you are a small business or a large manufacturer, the P400 Multi Bar Machine can revolutionize your production process, allowing you to meet the growing demand for nutritious and delicious protein bars in a timely and efficient manner.

The P400 multi row protein rod making machine is designed specifically for various rod shapes, such as rod, circular, disc, bite, pyramid, etc. It can be made into protein sticks, date sticks, fruit sticks, energy sticks, power sticks, nutrition sticks, coconut sticks, biscuits, etc., whether it is a hard or soft mixture or dough.

Advantage:

The multi row protein bar extruding machine can make protein bar,date bar,nutrition bar,power bar and so on.

The multi row protein bar extrusion line is full automatic PLC control with touch screen, high configuration with Delta brand,stable to work.

Full automatic soft materials production line with extruding and packing functions, Fast speed for cutting and packing.

2 touch screens (for extruder & packing machine) to make two machine can work separately or together.

Contact parts use food grade SUS304 stainless steel, save and clean.

Reduce manual operation and avoid touching products, no pollution and deformation.

Accurate length cutting, high gram precision.

Machine with stable performance,easy operation.

Independent PID temperature control, good for different packing film sealing.

With auto alarm function, any alarm will show on touch screen.

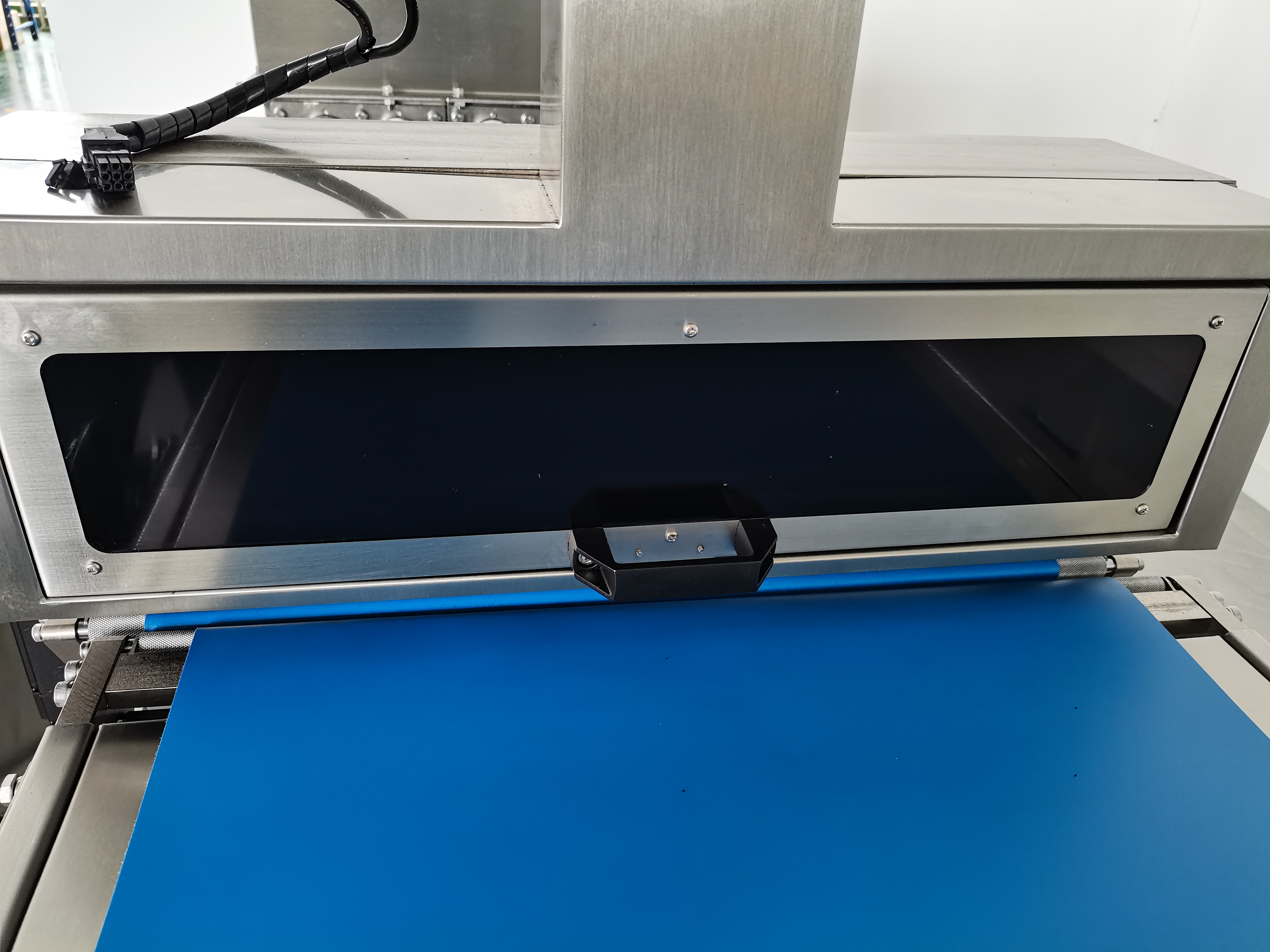

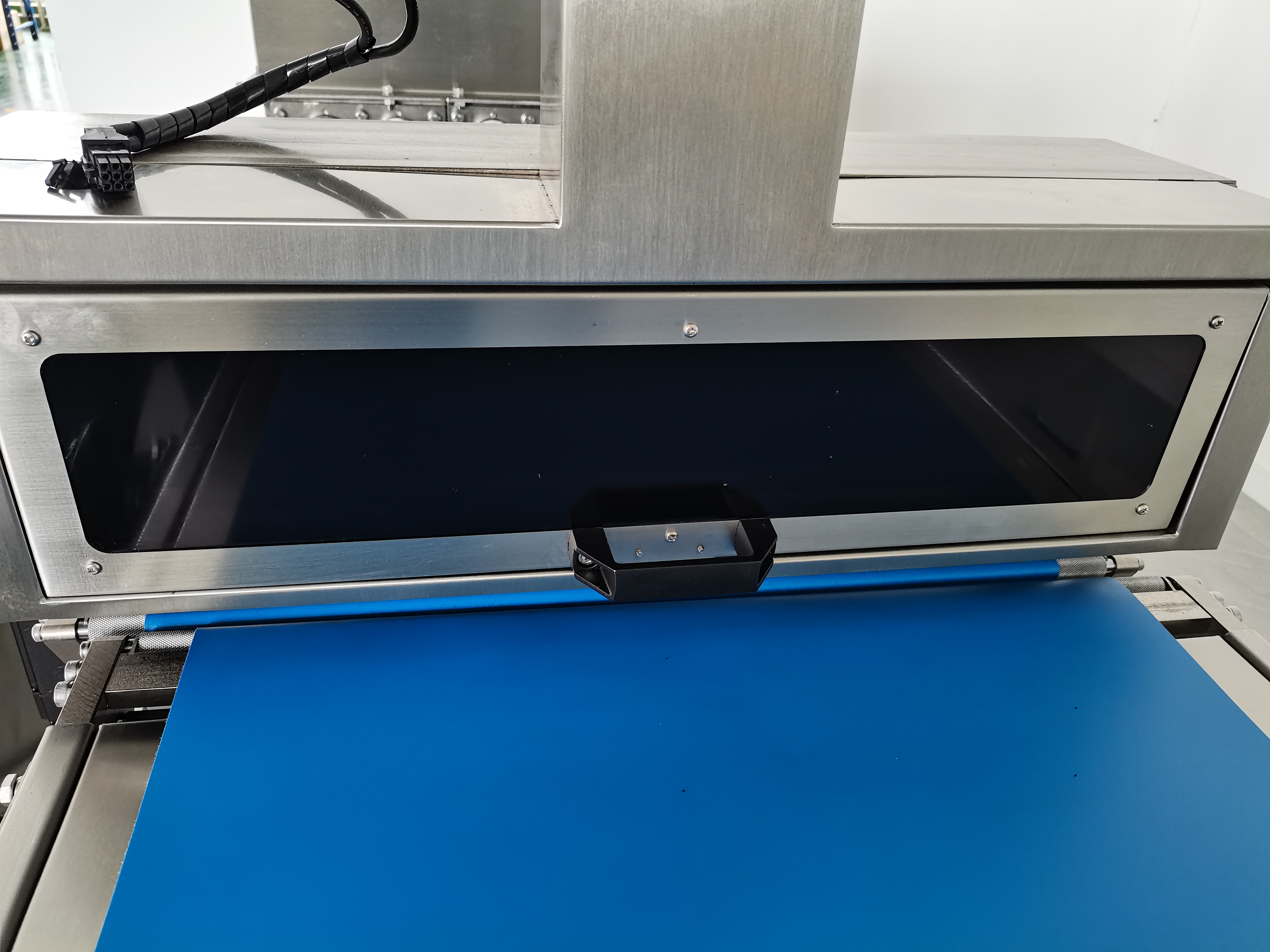

Protein bar extruding machine extruder and automatic Horizontal Flow packing Machine

Protein bar extruding machine features:

* Machine body & Hopper,and roller made by 304 Stainless steel.

* Custom designed nozzle make different size bars.

* Available to make multiple rows at one time, not only suitable for small capacity business usage, but also in big capacity business.

* Extruder and cutter separately design makes the machine easy for cleaning and .

* Machine completely packed and sent before shipment, no need installation, just connect electricity.

* Automatic control, just changing numbers on screen.

Multiple lanes protein bar production line for trapezoid shape bar machine video :

High capacity multirow protein bar date bar fruit bar making machine working with flow packing machine

The automatic flow packing syterm is used for aut bar sorting prefeeding and automatic packing . it has the function of counting bar numbers , sorting bars , packing bars , no need workers ,it is fully automtaic systerm .. it largely saves the time and labor .