Description :

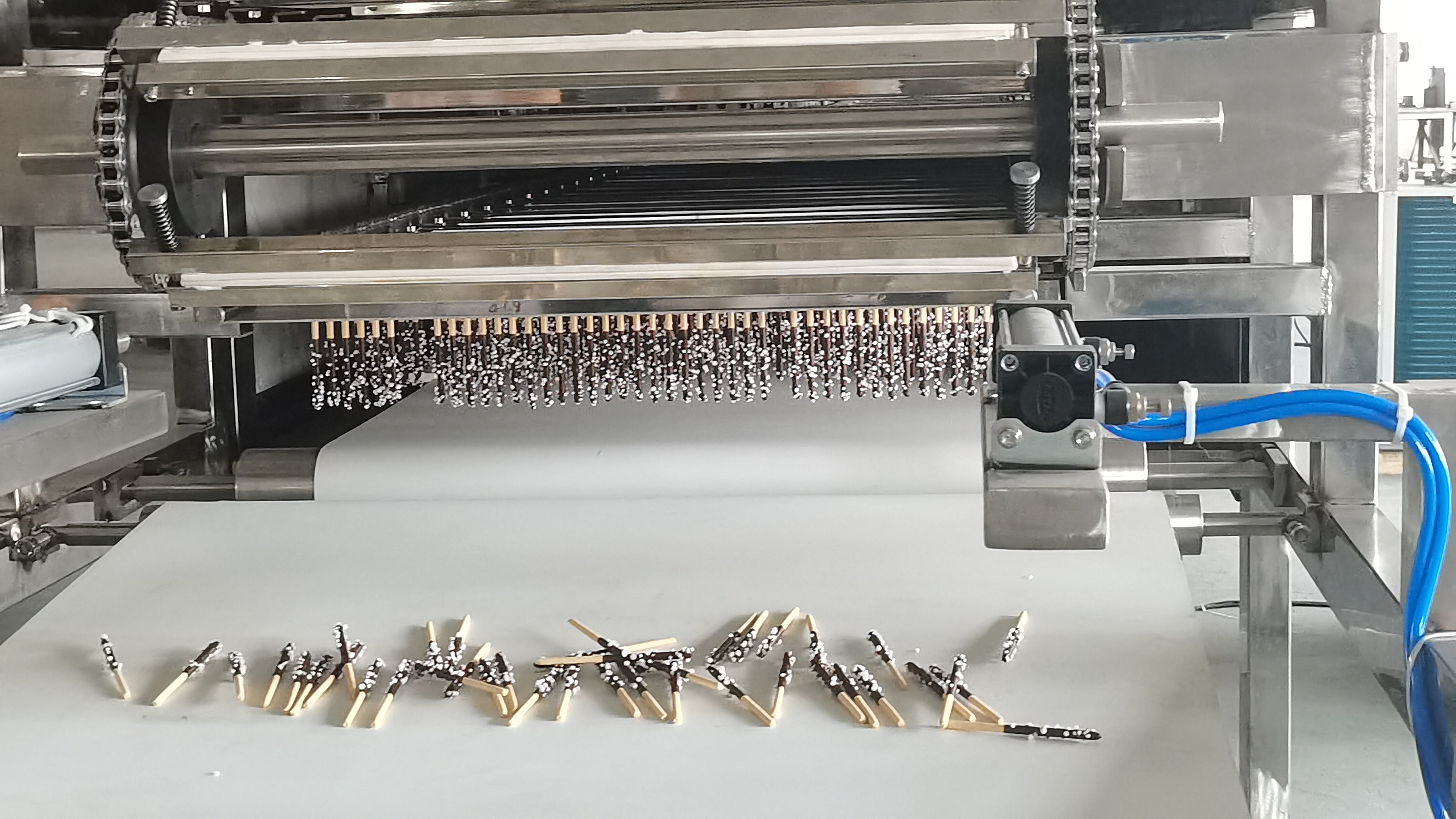

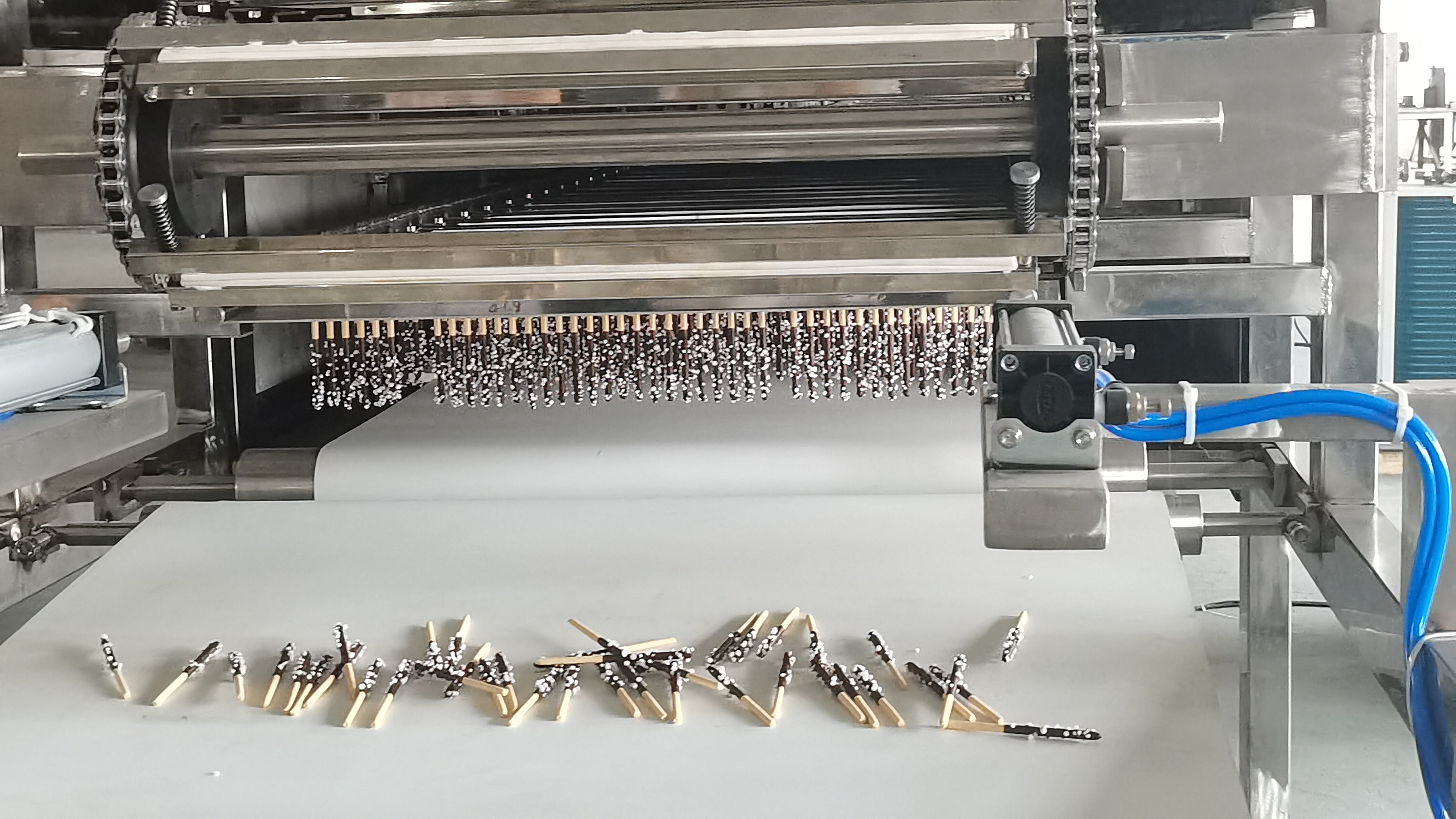

This specialized finger sticks chocolate coating production line is designed for coating finger biscuits with chocolate, offering automated material handling, biscuit lifting, clamping, coating, cooling, and stripping processes. By minimizing manual intervention, it significantly enhances product quality, safety, and consistency.

Employing electric, gas, and photoelectric tracking controls, this production line ensures a high level of automation, maintaining a consistent liquid coating level, smooth product finish, and uniform coating thickness. It stands as a cutting-edge finger biscuit coating system in China.

Following the initial coating, the material undergoes a sprinkling process, followed by a brief cooling period before the second coating application. Subsequently, the biscuits pass through a cooling tunnel for further processing.

Specification :

Model | 900 |

Wire mesh and belt width(mm) | 900 |

Wire mesh and belt speed (m/min) | 1-10 |

Refrigeration unit(set) | 5P -3sets |

Cooling tunnel lenth(m) | 20 |

Cooling tunnel temperature (°C) | 2-10 |

Total power(kw ) | 23.8 |

Weight(kg) | 3400 |

Dimension(mm) | 24200*1450*1800 |