P307 Protein bar machine working video :

P307 Protein bar machine work with chocolate enrober and flow packing machine to produce

chocolate protein bar ,chocolate date bar , chocolate energy bar .

Feature of P307 protein bar date bar energy bar machine :

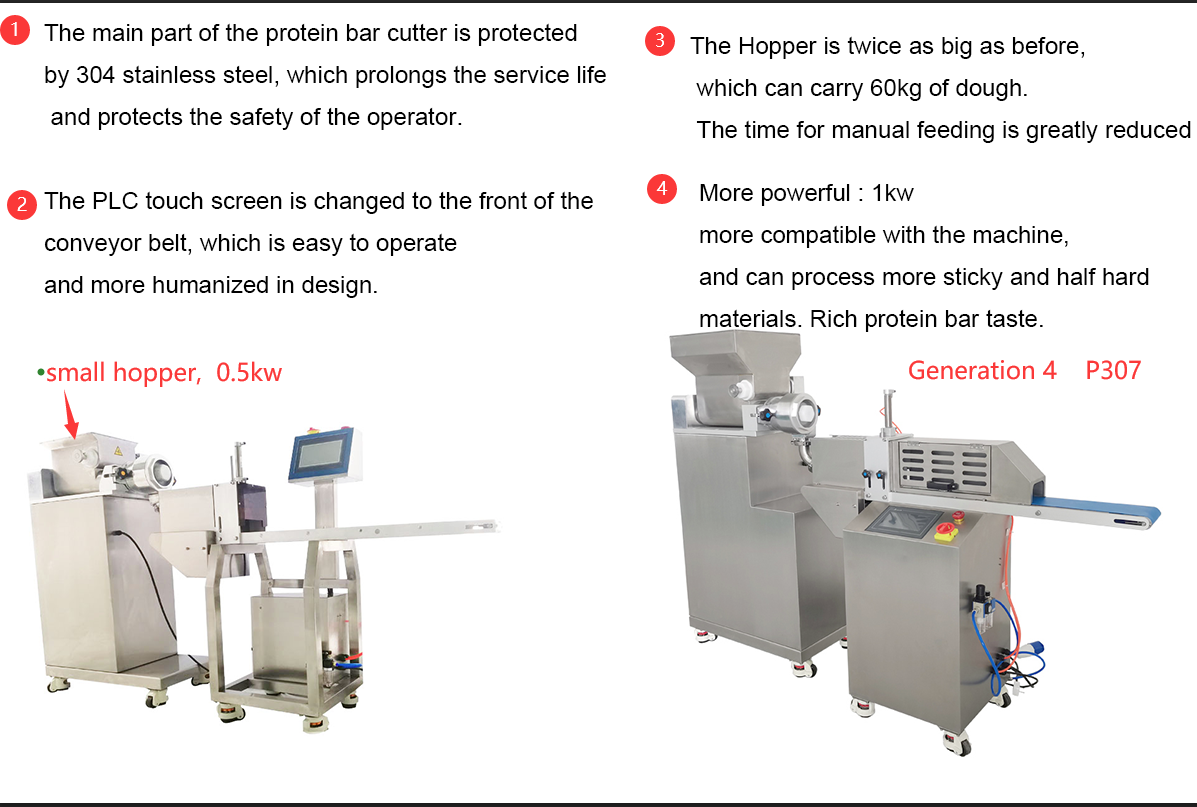

P307 has been updated into generation 4 type :

(1) Machine body 304 stainless steel , not only food touched area, but also whole machine body.

(2) The main part of the protein bar cutter is protected by 304 stainless steel , long service life and protect the safety of operator .

(3) The PLC touch screen is changed to the front of the bar feeding conveyor belt, more easy to operate and more humanized in design .

(4) The protein bar dough hopper is twice as big as old P307 extruder . currentl can load 60kg dough.

save time for add dough hopper . working long stable . reduce waste .

(5) More powerful :1kw more compatible with the machine. and can process more sticky and half hard materials. Rich protein bar taste.

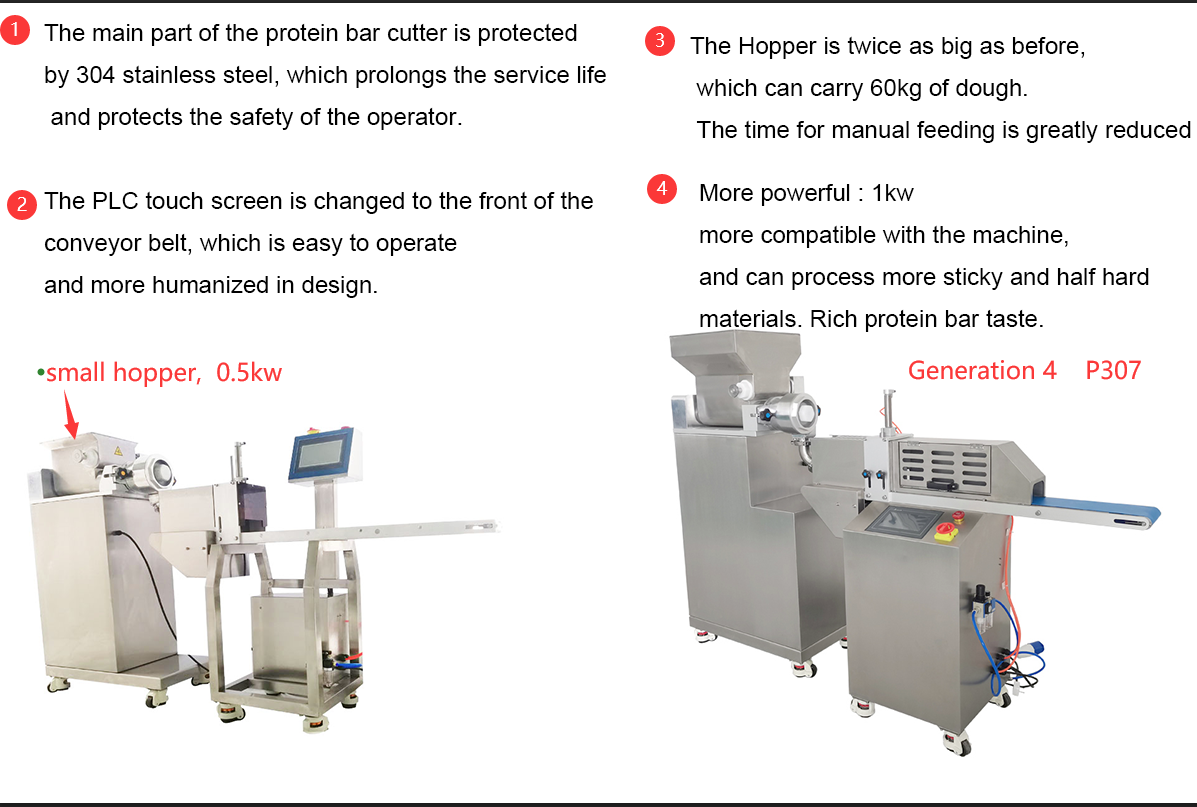

There are generation 3 and generation 4 type P307 dough extruder difference in details :

Optional protein bar flow packing machine :

flow wrapping machine to pack snack bars, PA250 model is the ideal protein bar wrapping machine, snack bar wrapping machine, fruit bar wrapping machine, candy bar wrapping machine, cereal bar wrapping machine, chocolate bar wrapping machine, and granola bar packaging machine, Papa Industrial also uses the flow wrapping machine to pack cookies and maamouls.

No matter a flow wrapping machine or a fully automatic flow wrapping production line, Papa Industrial can provide you turnkey solution for food packaging !