Description :

P307 Protein bar extruding and cutting machine is our fourth upgration model protein bar machine on the basic of our P307 model protein bar making machine, the protein bar making machine is suitable for making various bars and cookies like energy bar, fruit bar, chocolate bar, vegan bar, nutrition bar, protein bar, date bar, praline bar, crackers, fish crackers, halava, cheese bar ,allergie free bar and other food bars.

The protein bar extrder machine utilizes a horizontal design with double rolling screws to ensure successful extrusion of the dough into the rectifier. Additionally, there is an extra roller positioned on top of the hopper, which rolls down the mixture to prevent any mixture from coming out. This design ensures the production of protein bars with a perfect shape.

The rectifier plays a crucial role in guaranteeing uniformity in size and weight of the protein bars. It ensures that each bar is consistently shaped and of equal weight by regulating the extruded dough. This ensures that the final protein bars meet the desired specifications.

Overall, the protein bar extruder machine's horizontal type with double rolling screws and the inclusion of a rectifier and an additional roller on top of the hopper contribute to the successful extrusion of dough, the formation of perfect bar shapes, and the maintenance of consistent size and weight for each protein bar.

Protein bar making machine extruder and cutter are independently controlled by PLC system with touch screen english operation panel, so the protein bar machine is easy for operating and working in a stable condition.

The protein bar cutting machine adjusts the bar length by guillotine cutter, and bar width and thickness by changing nozzles.

As the protein bar manufacturing machine is a multifunctional type snack bar machine to make so many kinds of bars, so it is also called energy bar making machine, nutrition bar extruding and cutting machine ,date bar making machine or fruit bar making machine. They share same model P307. This P307 model protein bar making machine is our most hot selling food bar machine exported all over the world, especially in USA, UK and India.

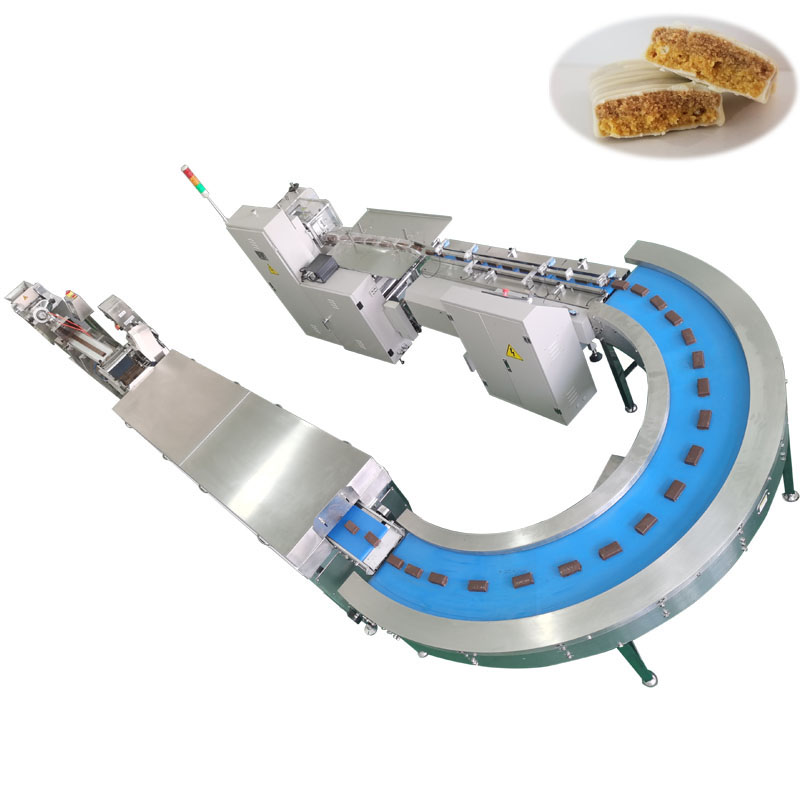

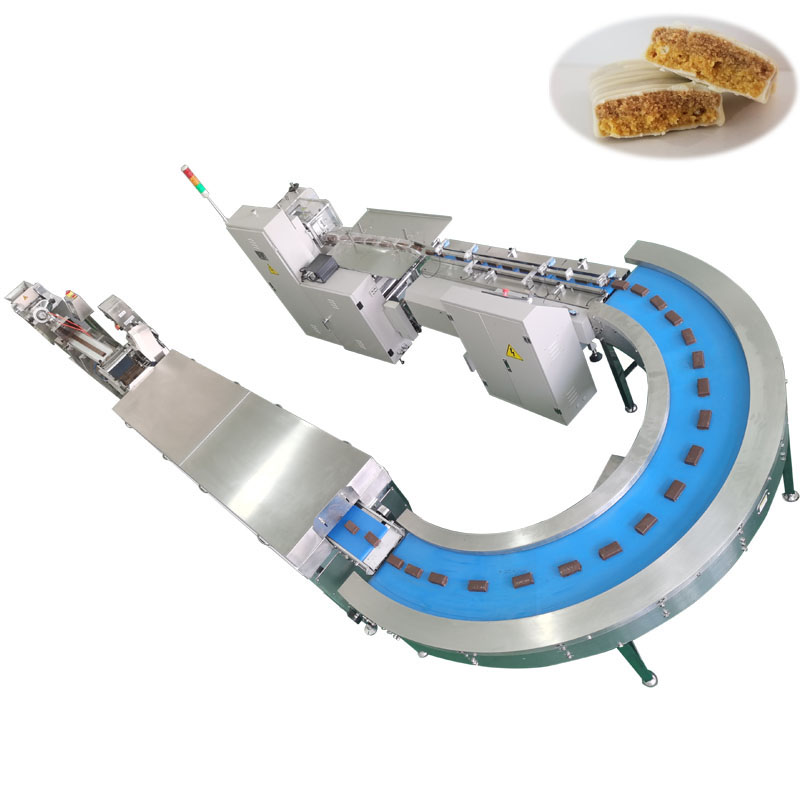

Furthermore, to establish a comprehensive protein bar production line, you can incorporate additional equipment immediately after the protein bar extrusion machine. This includes a small chocolate enrober, a cooling tunnel, and an automatic protein bar packaging machine. By integrating these components, you can create a fully automated protein bar production system that significantly reduces costs and enhances overall efficiency.

Small chocolate enrober: This machine serves the purpose of coating the protein bars with a layer of chocolate. It ensures a smooth and consistent chocolate coating, enhancing the taste and visual appeal of the bars. The enrober evenly distributes the chocolate, resulting in a professional and enticing appearance.

Cooling tunnel: Once the protein bars are coated with chocolate, they need to be properly cooled and solidified. The cooling tunnel provides an optimized environment where the bars pass through a refrigerated system. This facilitates the hardening of the chocolate, ensuring that it sets correctly and maintains its shape and structure.

Automatic protein bar packaging machine: After the protein bars have been coated and cooled, they can be automatically packaged using a specialized Automatic flow packaging machine. This machine efficiently wraps the bars in suitable packaging materials, such as film or wrappers, and securely seals them. It is capable of handling high production volumes while maintaining consistency in packaging, resulting in time and labor savings.

Protein bar extruder features:

* Machine body & Hopper made by 304 Stainless steel.

* Custom designed nozzle make different size bars.

* Available to make multiple rows at one time, not only suitable for small capacity business usage, but also in big capacity business.

* Extruder and cutter separately design makes the machine easy for cleaning and .

* Machine completely packed and sent before shipment, no need installation, just connect electricity.

* Automatic control, just changing numbers on screen.

Protein bar cutting machine features:

* Carbon steel cutting blade with teflon coated, suitable for cutting various bars.

* Pressing roller in front of the cutting blade help to stable the bar and anti-sticking.

* Safety guard around cutter see through inside, easy to remove and clean.

* Speed easy to control by changing numbers in the touch screen panel.

* Safety cover along the conveyor belt makes sure safety in production.

* Conveyor speed adjustable according to bar size.

Protein bar making machine specification:

Model | P307 Generation 4 type |

Output/capacity | 40-80pcs/min |

Product weight | 10-250g |

Power | 1 kw |

Voltage | 220V single phase/380V three phase |

Dimension | L181*W50*H136cm |

Weight | 220kg |

Material | 304 stainless |

Mould material | PU |

Conveyor | PE |

Protein bar making machine display:

Protein bar machine

Protein bar machine manufacturer

Protein bar machine supplier

Papa protein bar manufacturing machine is different from other cheap protein bar machine, we are one of the earliest manufacturer for protein bar manufacturing equipment in China, and we are using the most advance technology for the protein bar extruder and protein bar cutting. No matter you need a small protein bar machine or a whole protein bar production line, PAPA MACHINE will offer you the best solution.

Protein bar making machine food application:

Protein bar

cookie bar

fruit bar

date bar

date bites

energy bar

coconut bar

As the multifunctional food bar making machine, the protein bar making machine can meet your needs of small production, low cost and little space, Papa food bar machine will be one of your best choice.

protein bar making machine other food bar display:

Coconut bar making machine Crackers making machine Chocolate bar making machine

Date bar making machine Fruit bar making machine energy bar making machine

Protein bar extruding and cutting machine demo video:

Chocolate coated protein bar machine working video:

Chocolate bar extruder and chocolate coating machine with flow wrapping machine work video :

Tray arranging machine after protein bar cutting machine

Fully automatic arranging machine is suitable for food enterprises of scale production, it could pick up

products in the baking trays directly. It can avoid the destruction or contamination by hand before the

product is not baked, and can reach food hygiene standards.

Multifunctional planetary mixer before protein bar making machine machine

B series multifunction high speed mixer has a compact structure,with multifunction of egg whipping,

stuffing homogenizing,and dough mixing.

The machine has three level speed change:high level,middle level and low level.It is equipped with egg-whisk,pat shape beater,and spiral mixer for the operation of egg liquid mixing,cream mixing,stuffing

mixing and dough mixing.

Metal detector for protein bar manufacturing line

Very best performance for large effect products such as milk, sausage, fresh meat, fresh, sauce, filling,

salt & smoking products.

Widely use for detecting metals in food, pharceutical products, rubber, garment, plastic, beverage,

chemical and any other industrials to ensure product safety and protect your brand.

Checkweighter for protein bar manufacturing line

1. Based on high speed 32bit CPU control circuit.

2. Multi-functional OS and dual language.

3. High-precision auto adjustment for phase angle.

4. Intelligent product study mode can fit for more types of product.

5. Multi-functional stainless steel frame and adjustable height.

6. Large color LCD display, easy to operate.

7. Full digital signal processing and transferring.

8. Newly designed SUS machine frame with high protection grade.

9. Automatic rejection module.

10. Match different production lines.

11. Automatic product learningudying function.

12. Have moving wheels, height are adjustable.