Product Description

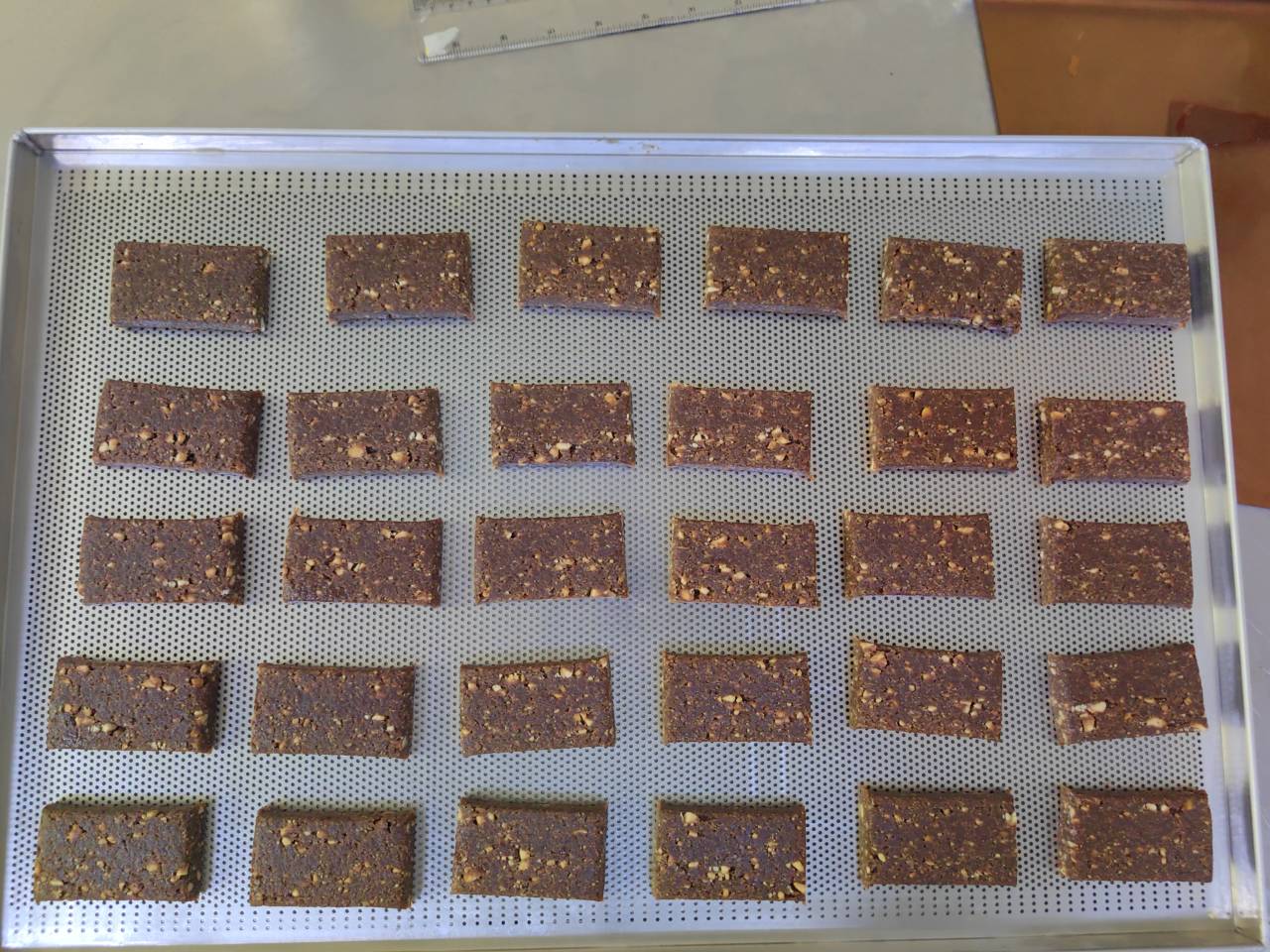

The P308 Protein Bar Machine is designed for versatility and precision, making it perfect for producing various food bars like protein bars, date bars, and vegan bars. Its high-torque motor easily handles hard dough, while its stainless steel extrusion screw ensures durability. Offering customizable settings for bar size and weight, this machine is ideal for manufacturers seeking a reliable and efficient solution for large-scale bar production.

Versatile Protein Bar Production

The P308 Protein Bar Machine is your all-in-one solution for producing a wide range of food bars, including protein bars, fruit bars, date bars, and energy bars. This machine features a powerful 380V, three-phase motor that delivers high torque, allowing it to easily extrude hard and dry mixtures. Its stainless steel extrusion screw technology ensures that even the toughest doughs are processed efficiently, making it suitable for various bar types, from vegan bars to nutrition bars.

Customizable Bar Settings for Optimal Production

With the P308 Protein Bar Machine, manufacturers can easily adjust the thickness, length, and size of the bars, ensuring precise control over product output. This machine offers multiple mold options, allowing for flexible production of different bar sizes and shapes. It also features advanced controls for managing dough extrusion speed, cutter speed, and cutter delay, providing consistency in bar weight and size. This makes it perfect for producing chocolate bars, energy bars, and other specialty food bars.

Seamless Integration with Food Production Lines

One of the standout features of the P308 Protein Bar Machine is its ability to integrate seamlessly into food production lines. Whether combined with a cooling tunnel for temperature-sensitive bars, a chocolate enrober for coated products, or a flow packing machine for automatic wrapping, this machine offers full production line compatibility. Additionally, it can be combined with ovens for baking bars like crackers or fish crackers, making it a versatile choice for any food manufacturer.

Product Features

High-Torque Motor: Equipped with a 380V, three-phase motor designed for heavy-duty use, perfect for handling tough and dry mixtures.

Stainless Steel Extrusion Screw: Durable 304 stainless steel construction ensures long-lasting performance and easy maintenance.

Adjustable Bar Settings: Allows for precise control over bar thickness, length, and size, with options to change molds for different bar shapes.

Advanced Control Features: Manages extrusion speed, cutter speed, and delay for consistent bar weight and size.

Integration Capabilities: Compatible with cooling tunnels, chocolate enrobers, flow packing machines, and ovens, enhancing production efficiency.

Wide Range of Bar Types: Suitable for producing protein bars, date bars, fruit bars, vegan bars, nutrition bars, and more.

Product Advantage

The P308 Protein Bar Machine stands out in the market for its unmatched versatility, durability, and precision. Its high-torque motor and stainless steel extrusion screw make it capable of handling even the hardest and driest mixtures, offering a significant advantage over standard extruders. With customizable bar settings, this machine ensures consistency in size and weight for a wide range of products, from protein bars to chocolate bars. Its ability to integrate seamlessly with other food production equipment—such as cooling tunnels, chocolate enrobers, and flow packing machines—enhances production efficiency, making it an ideal solution for both small-scale and large-scale manufacturers. Additionally, the robust construction and high-quality components ensure long-term reliability, reducing maintenance downtime and boosting operational productivity.

Maintenance Tips

Clean the stainless steel parts regularly to avoid buildup. Ensure the motor and extrusion screw are lubricated and inspected for wear and tear to maintain optimal performance.

P308 protein bar machine specification :

Model

| P308 |

Output/capacity | 40-80pcs/min |

Product weight | 10-250g |

Power | 4 kw |

Voltage | 380V three phase |

Dimension | 2550*760*1400mm |

Weight | 400kg |

Material | 304 stainless |

Application : protein bar,cookie bar,fruit bar,date bar,date bites,energy bar,coconut bar,chocolate bar ,Nutrition bar , fruit paste bar

P308 Horizontal protein energy bar extruder video:

Optional machine to match this protein bar extruder :

1. Chocolate enrober /chocolate coating machine

The biscuit Chocolate Enrobing Line is the small chocolate coating machine specially designed for small scale chocolate industries,there are many bakery shop or confection who need make chocolated coated food,but they have very limited operation space and small chocolate production demand,so they need a small chocolate enrober,which can make the customers can use it to make the end chocolate coated product with consistent weight,uniform thickness and perfect finish.

The Chocolate enrobing machine is used for coating chocolate around food or on bottom of food, such as cereal bars, energy bars, protein bars, candy bars, rice bites, wafers and wafer stick, birthday cakes, cakes, breads, rolls, pies, muffins, snacks, candies, confectionery, maamoul and mooncakes, cookies, biscuits, crackers, cake ball, date ball and chocolate truffles,etc,the commercial chocolate enrober machine is small sized and easy operation.Customer can choose to connect air fan cooling or tunnel cooling after the chocolate enrober machine.

chocolate bar production line video :

2. Planetary mixer

The multi-function high speed planetary mixer has a compact structure,with multi-function of egg whipping,stuffing homogenizing,and dough mixing. it is the essential equipment for materials mixing.

3, Protein bar flow wrapper packing machine

Fully Automatic protein bar packing line is a horizontal packing machine with automatic connection conveyor with tracking sensor,which can make the customers put the product on the conveyor belt casually and the conveyor can move the product to the packing machine precisely to be packed with good sealing.The protein bar packing machine also called pillow-type packing machine because the shape of the finished bag is pillow-like. The machine has good stability, low maintenance cost can be used continuously, and is famous for its high cost performance. No manual intervention is required in the whole packaging process, the packaging process is safe and reliable, and the degree of automation is high.

flow packing machine video :

This machine is suitable for packing all kinds of solid and regular products. For packing food: biscuits, bread, instant noodles, ice cream, moon cakes, soft sweets, etc.; other categories such as: soap, Fengyoujing, pocket notebooks, boxed pens, tape, regular-shaped medicines and others. This machine has good sealing performance, clear sealing, neat, flexible, fast, compact structure, running smooth, stable rotation and low noise.

smart conveyor :

FAQs

Q: Can this machine handle tough and dry doughs?

A: Yes, the P308 Protein Bar Machine is designed with a high-torque motor to handle hard, dry, and sticky mixtures.

Q: What types of bars can I produce with this machine?

A: This machine is ideal for protein bars, date bars, energy bars, fruit bars, chocolate bars, vegan bars, and more.

Q: Can the machine be integrated into an existing production line?

A: Yes, the P308 can integrate with cooling tunnels, chocolate enrobers, flow packing machines, and even ovens for a complete production solution.

With the P308 Protein Bar Machine, manufacturers gain access to powerful extrusion technology, customizable production settings, and seamless integration capabilities, making it the perfect choice for high-volume protein bar production and beyond.

Papa Industrial mainly uses the flow wrapping machine to pack snack bars, PA250 model is the ideal protein bar wrapping machine, snack bar wrapping machine, fruit bar wrapping machine, candy bar wrapping machine, cereal bar wrapping machine, chocolate bar wrapping machine, and granola bar packaging machine, Papa Industrial also uses the flow wrapping machine to pack cookies and maamouls. No matter a flow wrapping machine or a fully automatic flow wrapping production line, Papa Industrial can provide you turnkey solution for food packaging ! Weclome to contact us for more information !