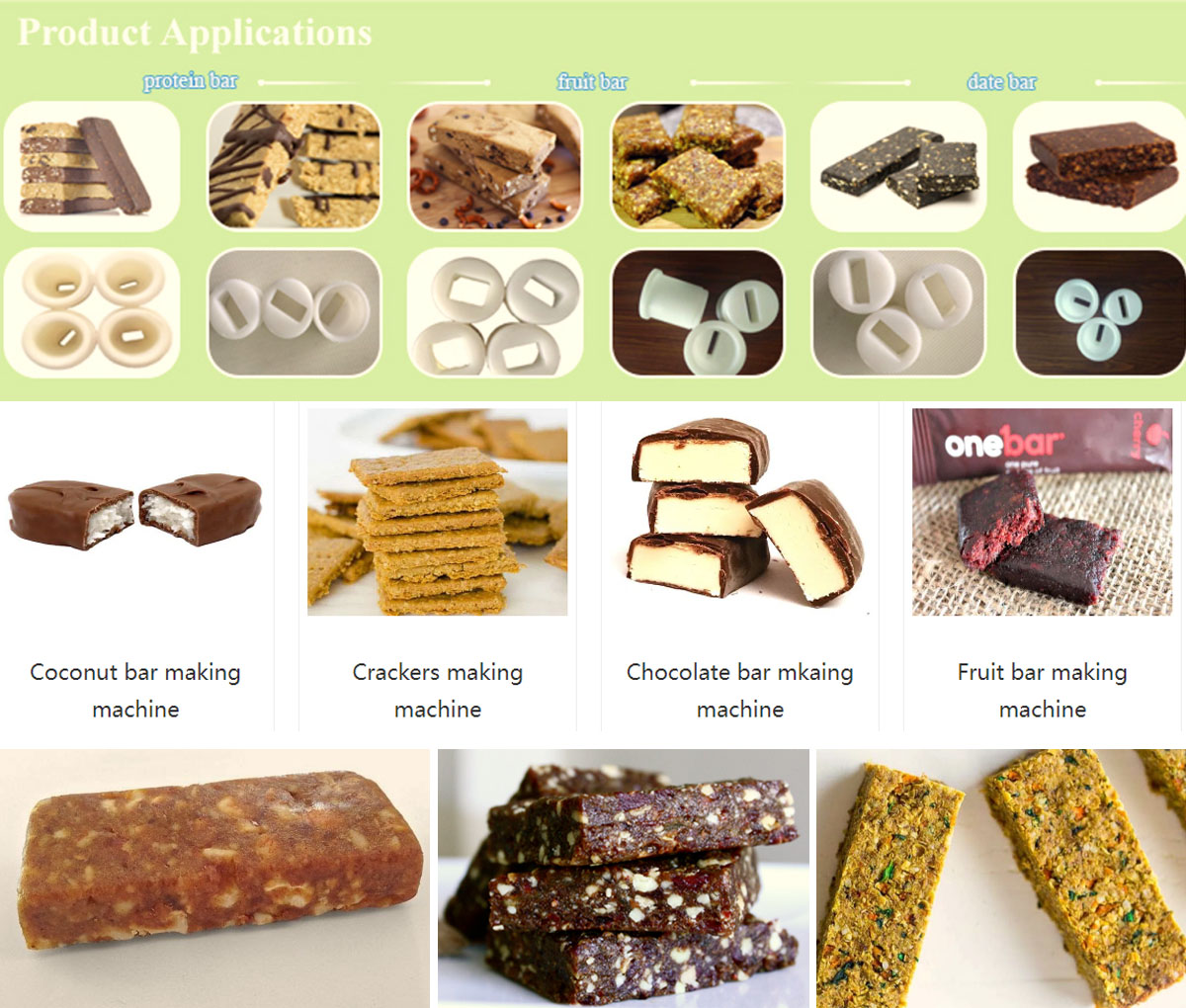

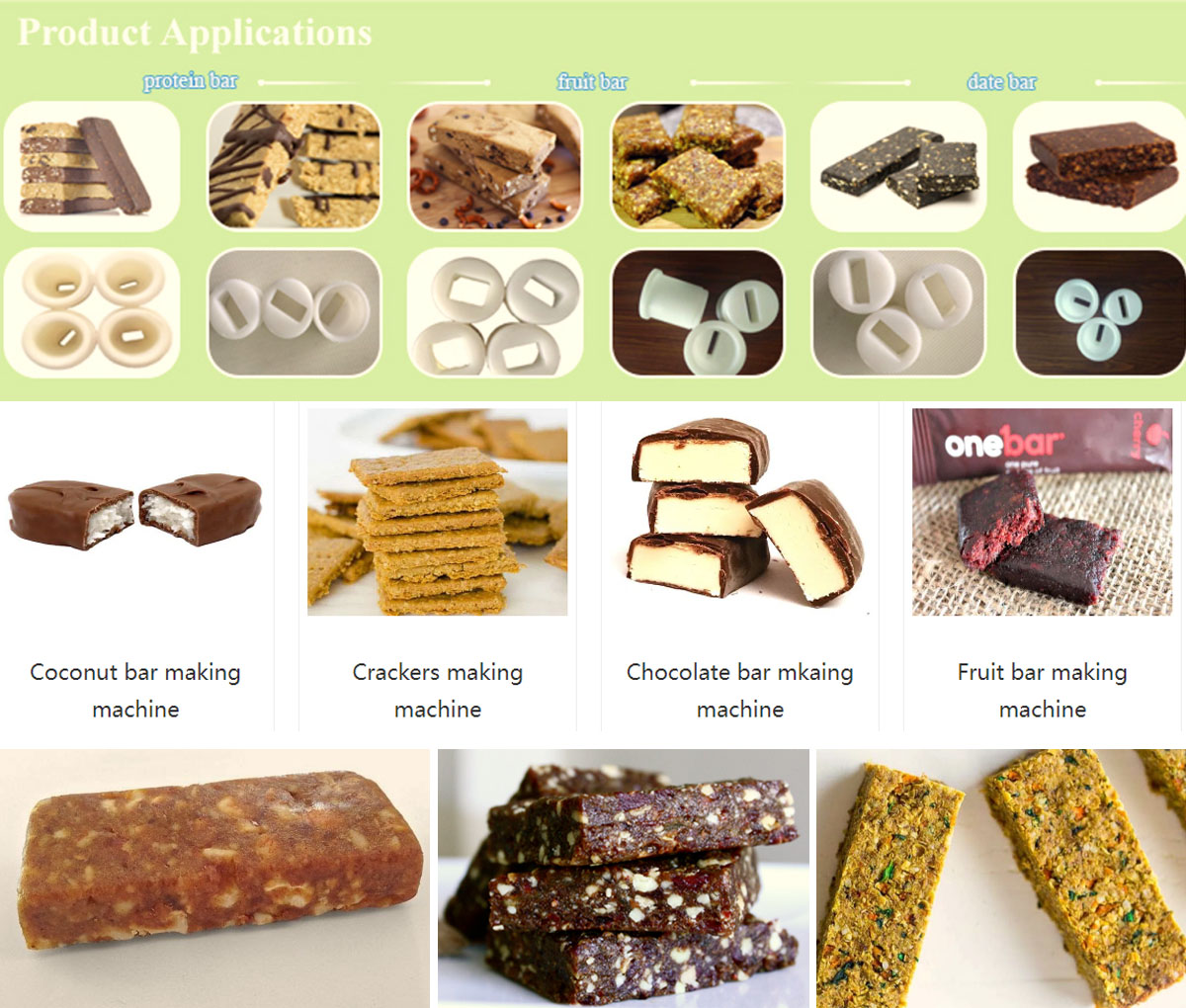

Product Overview

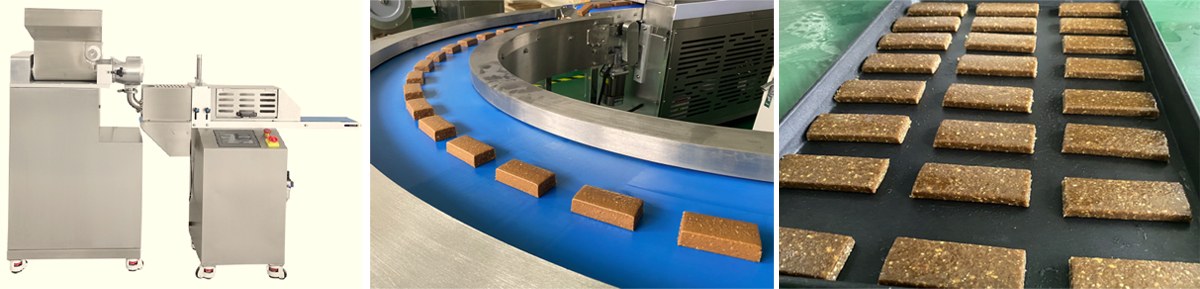

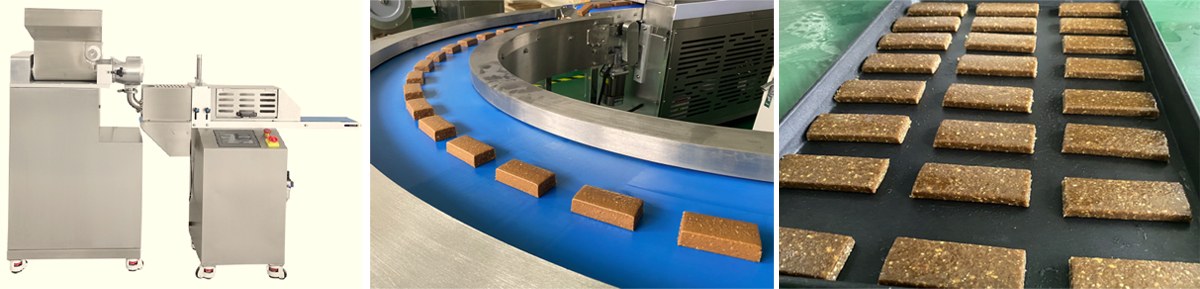

The Chocolate Protein Bar Extruding Machine is a high-capacity, advanced machine for producing various protein bars, including chocolate, energy, and vegan bars. Featuring a 60 kg hopper, dual screw technology, and a user-friendly PLC control system, it ensures efficient production with customizable bar shapes and precision cutting.

The Chocolate Protein Bar Extruding Machine is ideal for creating diverse bars such as protein bars, energy bars, and vegan bars. With its large-capacity high capacity hopper and advanced extrusion technology, this machine optimizes dough processing and bar shaping. The dual screw system ensures thorough mixing, while the customizable nozzle allows for precise bar formation. Its PLC control system simplifies operation, making it perfect for modern snack production.

1. Efficient High-Capacity Production

The Chocolate Protein Bar Extruding Machine is designed for high-volume production of protein bars and energy bars, making it a versatile solution for snack manufacturers. The 60 kg high capacity hopper allows for larger batches, minimizing refill times and increasing productivity. The dual screw technology ensures optimal dough mixing and extrusion, delivering consistent results for vegan bars, chocolate bars, and other healthy snacks. This machine significantly improves operational efficiency for companies focused on snack production.

2. Precision Extrusion and Customizable Shapes

The machine's advanced extrusion technology guarantees that each protein bar is perfectly shaped and uniform in size. Its customizable nozzle lets manufacturers create bars in various shapes, including rectangular, round, or strip designs, enhancing product variety. The integrated rectifier ensures that all bars maintain their structural integrity during production. This precision is crucial for maintaining quality control in snack manufacturing, ensuring every bar meets industry standards.

3. User-Friendly Operation and Flexibility

Equipped with an intuitive PLC control system, the Chocolate Protein Bar Extruding Machine is easy to operate. Users can adjust extrusion and cutting settings with just a few touches, streamlining the process for efficient, high-quality bar production. The machine also features an automatic cutter with an adjustable conveyor system, enabling precise cutting of bars to the desired size. The cutter's Teflon-coated carbon steel blade ensures clean cuts, while the adjustable conveyor belt offers safety and flexibility to produce different sizes and types of bars, including vegan bars and energy bars.

Key Product Features

Stainless Steel Build: Durable 304 stainless steel construction for longevity and hygiene.

Customizable Nozzles: Allows for different bar shapes and sizes, enhancing production flexibility.

High Capacity Hopper: A 60 kg hopper for continuous dough processing, minimizing downtime.

Dual Screw Technology: Ensures consistent dough movement and thorough mixing for protein and energy bars.

Advanced Extrusion Technology: Provides precise shaping for protein bars, vegan bars, and other snacks.

Automatic Cutter: Equipped with a Teflon-coated carbon steel blade and an adjustable conveyor system for safe, efficient cutting.

PLC Control System: User-friendly touch screen for easy operation and adjustment.

Compact Design: Ideal for small and medium-sized production facilities, maximizing space without compromising capacity.

How to Maintain the Chocolate Protein Bar Extruding Machine

Regular Cleaning: Clean the machine after every use, focusing on the hopper, extrusion area, and cutting blades. Use warm, soapy water and soft sponges to preserve the stainless steel surfaces.

Lubrication: Regularly lubricate the moving parts, particularly the screws and conveyor components, following the guidelines in the user manual.

Inspection: Conduct periodic inspections for wear and tear, ensuring all components like the customizable nozzle and rectifier are in top working condition.

Calibration: Recalibrate the machine periodically to maintain precision in bar shaping and cutting, especially when switching between different bar types like protein bars and energy bars.

Software Updates: Ensure the PLC control system is regularly updated to benefit from performance improvements and new features.

Product shape:bar, rectangular, round, strip, and etc.

Machinery specification:

Model | P307 Generation 4 type |

Output/capacity | 40-80pcs/min |

Product weight | 10-250g |

Power | 1 kw |

Voltage | 220V single phase/380V three phase |

Dimension | L181*W50*H136cm |

Weight | 220kg |

Material | 304 stainless |

Mould material | PU |

Conveyor | PE |

Application: Date bar, protein bite, energy bar, cookie bar, fruit bar, date bites, coconut bar, healthy bar, snack bar, Nutrition bar

Small chocolate enrober:

The automatic chocolate coating machine consists of small chocolate enrober and 3P Chocolate cooling tunnel or cooling fan conveyor belt. The 3P cooling tunnel can do the fast cooling for the chocolate,the temperature can be up to-18 degree and the length of the cooling tunnel is 3.2m, once the food coated, it will flow into the cooling tunnel and can get cold well so that the customer can direclty do the packing. The cooling fan conveyor is usually used for the food that don't need fast cooling.

chocolate coating machine with a 3P cooling tunnel is a specialized piece of equipment used for coating confectionery items with chocolate and then rapidly cooling them to solidify the chocolate coating.

The chocolate coater chocolate enrober machine consists of two main parts: the chocolate coating section and the cooling tunnel section. In the chocolate coating section, the machine typically features a stainless steel tank or bowl for melting and tempering the chocolate. The chocolate is heated to a precise temperature and consistency to ensure smooth and glossy coatings on the confectionery items.

A conveyor belt is used to carry the items through the chocolate, fully coating them. The coating thickness can usually be adjusted to cater to different preferences. After being coated with chocolate, the items are then transferred onto the conveyor belt of the cooling tunnel section. The cooling tunnel is designed with multiple levels, and the items are placed on trays or trays that are loaded onto the conveyor belt at the entry of the tunnel. The cooling tunnel utilizes a 3P (Pressure, Position, and Path) cooling system to rapidly cool down the coated items. This process is crucial to solidify the chocolate coating quickly and prevent any potential melting or smudging.

The cooling tunnel typically consists of a series of fans, blowers, or refrigeration units that direct cold air to circulate around the products. The temperature and speed of the cooling process can usually be adjusted to cater to different types of confectionery items and specific coating requirements. As the conveyor belt moves through the tunnel, the items gradually cool down and the chocolate coating hardens. Overall, a chocolate coating machine with a 3P cooling tunnel is a comprehensive system that ensures efficient and high-quality chocolate coatings.

It combines the capabilities of coating the confectionery items with chocolate and quickly cooling them to achieve a smooth and solid chocolate finish.

PE8/PE15/PE30/PE60 Commercial small chocolate enrober specifications:

Model | PE8 | PE15 | PE30 | PE60 |

Capacity | 8KG chocolate/batch | 15KG chocolate/batch | 25KG chocolate/batch | 5KG chocolate/batch |

Belt speed | 2meter/min | 2meter/min | 2meter/min | 2meter/min |

Enrober mesh belt width | 180mm | 180mm | 180mm | 300mm |

Tunnel PU belt widh | 200mm | 200mm | 200mm | 400mm |

Heating method | Electric heating | Electric heating | Electric heating | Electric heating |

Voltage | 220V, single phase | 220V, single phase | 220V, single phase | 220V, single phase |

Power | 1.8kw | 2kw | 2.8kw | 3.1kw |

Dimension | 2000x5701350 | 2000x640x1350 | 3200x710x1350 | 3400x910x1400 |

Weight | 80KG | 100kg | 190kg | 240kg

|

Turning machine

Connecting conveyor for packing machine |

Product Description: Precise continuous feeding. | Packaging Details: Daub coal oil on the surface to protect the machine from moisture, then cover with plastic film. Finally pack them with wooden case. |

Brand Name | Model | Power (kw) | Voltage (V) | Dimension L*W*H (mm) | Output pcs/min | Machine weight (kg) | Packing weight (kg) | Packing Size (mm) | Warranty | Certification |

PAPA | ZP2000-1 | 0.3 | 220V Single phase (Customize) | 1760*400*900 | 35-180 | 300 | 350 | 1500*770*1220 | 1 | CE |

Flow wrapping machine(film downside wrapping)

This machine is suitable for packing all kinds of solid and regular products. For packing food: biscuits, bread, instant noodles, ice cream, moon cakes, soft sweets, etc.; other categories such as: soap, Fengyoujing, pocket notebooks, boxed pens, tape, regular-shaped medicines and others. This machine has good sealing performance, clear sealing, neat, flexible, fast, compact structure, running smooth, stable rotation and low noise.

Feature:

1)The main control circuit adopts inverter control, PLC touch screen display, and provided the good interface of person and machine. The machine operation is concentrated and intuitive;

2)The whole machine adopts dual frequency converter control, wide frequency conversion range, large speed adjustment range, which permits stepless variation. Packaging speed can be set by the production speed of the production line, and the matching is perfect.

3)After setting the packaging film length and the packing bag length, they are automatically controlled and tracked by a high-sensitivity electric eye. The bag length is accurate and not need to adjust by manual.

4)Each sealing temperature is independently controlled, suitable for a variety of packaging materials, and the sealing is beautiful and firm.

5)The printer can be configured according to the needs of users, so that the printing of production date, production batch number, etc. can be synchronized with the packaging.

Specifications and technical parameters | Packing speed (bag/min)

| 35-150 |

Packaging film width (mm) | 90-240 |

Bag size (mm) | Length(flat bag) | 85-300 |

Width | 30-100 |

Height | 5-30 |

Total power (kw) | 3.0 |

Main motor power (kw) | 0.75+0.75 |

Heating power (kw) | 1.2 |

Machine net weight (kg) | 600 |

Machine dimensions (length * width * height) (mm) | 1640×830×1350 |

Machine noise (dB) | ≤78dB |

Qualified rate of bagging (percentage) | ≥98% |

Sealing pressure (Newton/mm2) | 15 |

Voltage | 220V 50Hz |

Packaging film material | OPP, PE, PVC, OPP/CPP, PT/PE, KOP/CPP, Aluminum film etc. |

FAQs

1. What types of protein bars can this machine produce?

The machine can create a variety of bars, including chocolate protein bars, energy bars, and vegan options.

2. How large is the hopper?

The hopper holds up to 60 kg of dough, enabling larger batch production.

3. Is operation straightforward?

Yes, the machine is designed with a user-friendly PLC control system and touch screen interface for easy use.

4. What materials are used in the machine's construction?

It is made from high-quality materials to ensure durability and hygiene during production.

5. Can it handle both sweet and savory recipes?

Yes, it is versatile enough to accommodate a wide range of sweet and savory ingredients.

6. How does it maintain uniform bar sizes?

The integrated rectifier ensures that each bar is produced with consistent size and weight.

7. What maintenance is required?

Regular cleaning and periodic servicing are recommended, with detailed guidelines provided in the user manual.

8. Is training provided for new operators?

Yes, we offer training and support to ensure effective use and maintenance of the machine.

9. How does this model improve upon previous versions?

The P307 features a larger hopper and enhanced power, resulting in greater efficiency and ease of use compared to earlier models.

10. What warranty is offered?

Warranty details vary, so it’s best to consult with the supplier for specific coverage terms.