Product Description

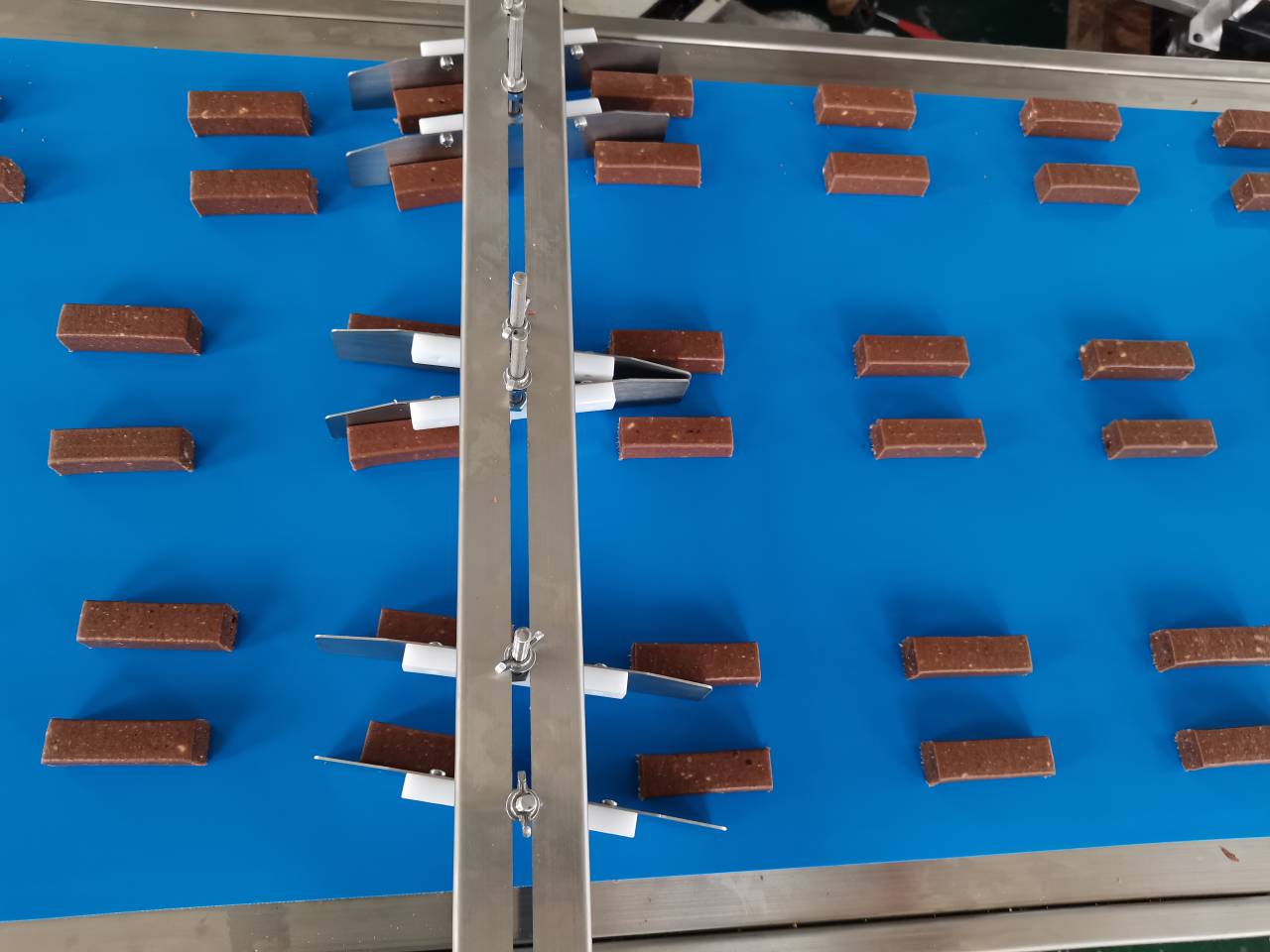

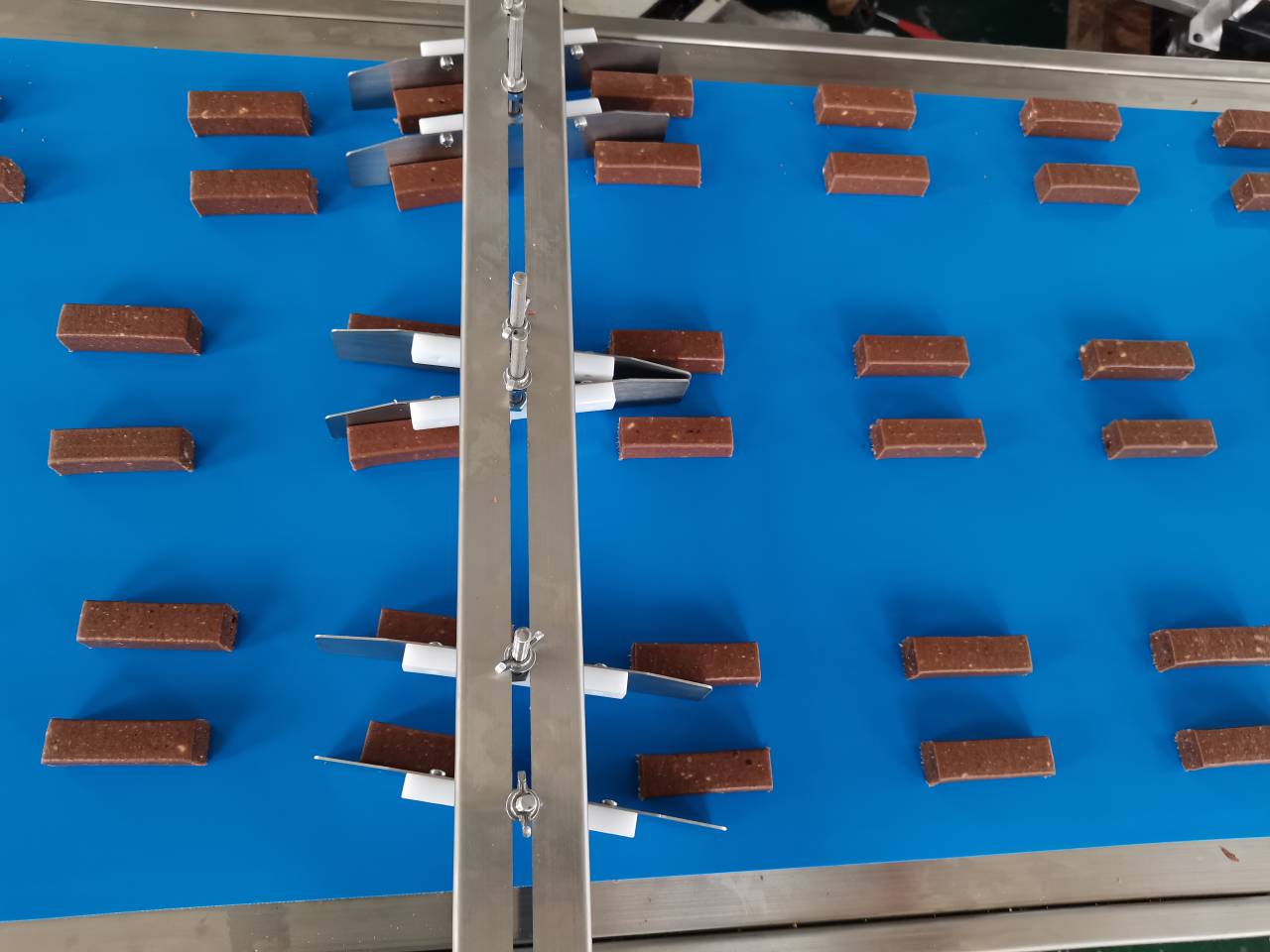

The P400 Protein Bar Extrusion Machine is designed for efficiently producing various shapes of bars, such as rods, discs, and bite-sized snacks. Crafted with 304 stainless steel, it is capable of processing both soft and firm mixtures, making it perfect for creating protein bars, energy bars, and date bars. This high-speed multi-row machine enhances productivity with minimal human intervention, providing a seamless production process.

Versatile Bar Production Capability

The P400 Protein Bar Machine allows manufacturers to produce a variety of bar shapes, including rods, discs, pyramids, and small bite-sized pieces. It is suitable for creating an assortment of products, including protein bars, date bars, almond bars, and chocolate bars. Whether the mixture is firm or soft, the machine ensures accurate extrusion and cutting for perfectly shaped bars.

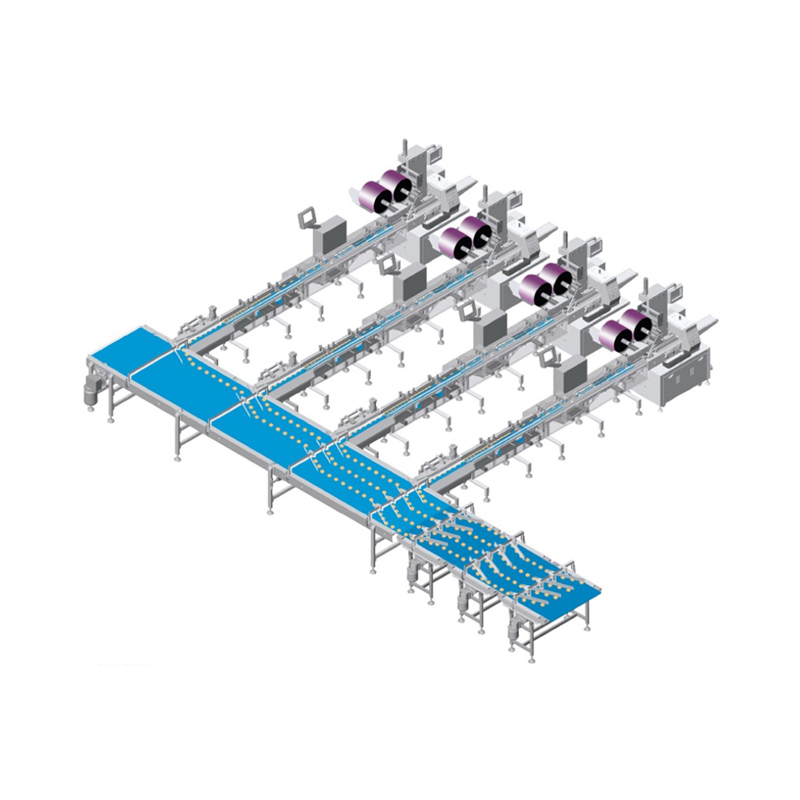

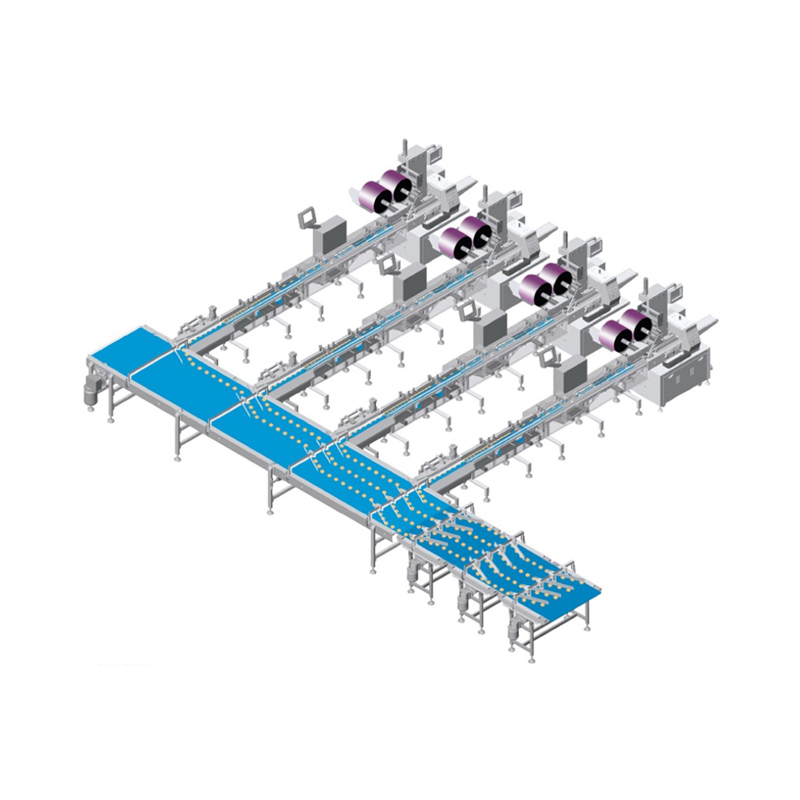

Flexible Integration with Food Processing Equipment

This P400 bar production machine can be utilized on its own or integrated with other processing systems, making it adaptable to various production needs. It can easily be paired with cooling tunnels for products that require temperature regulation or combined with automatic packaging systems for streamlined operations. Additionally, it can be used alongside chocolate cooling systems for frosted or coated products.

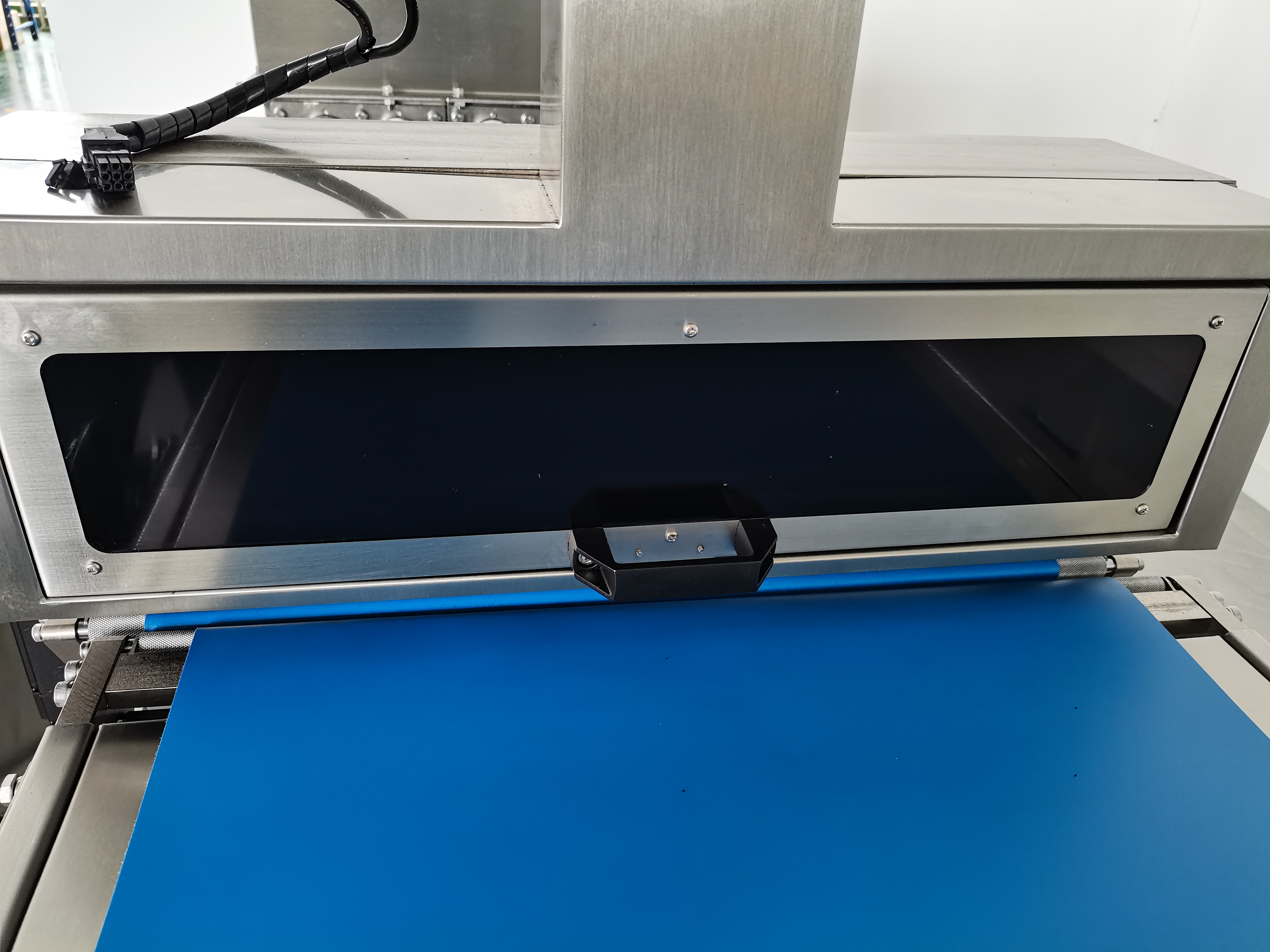

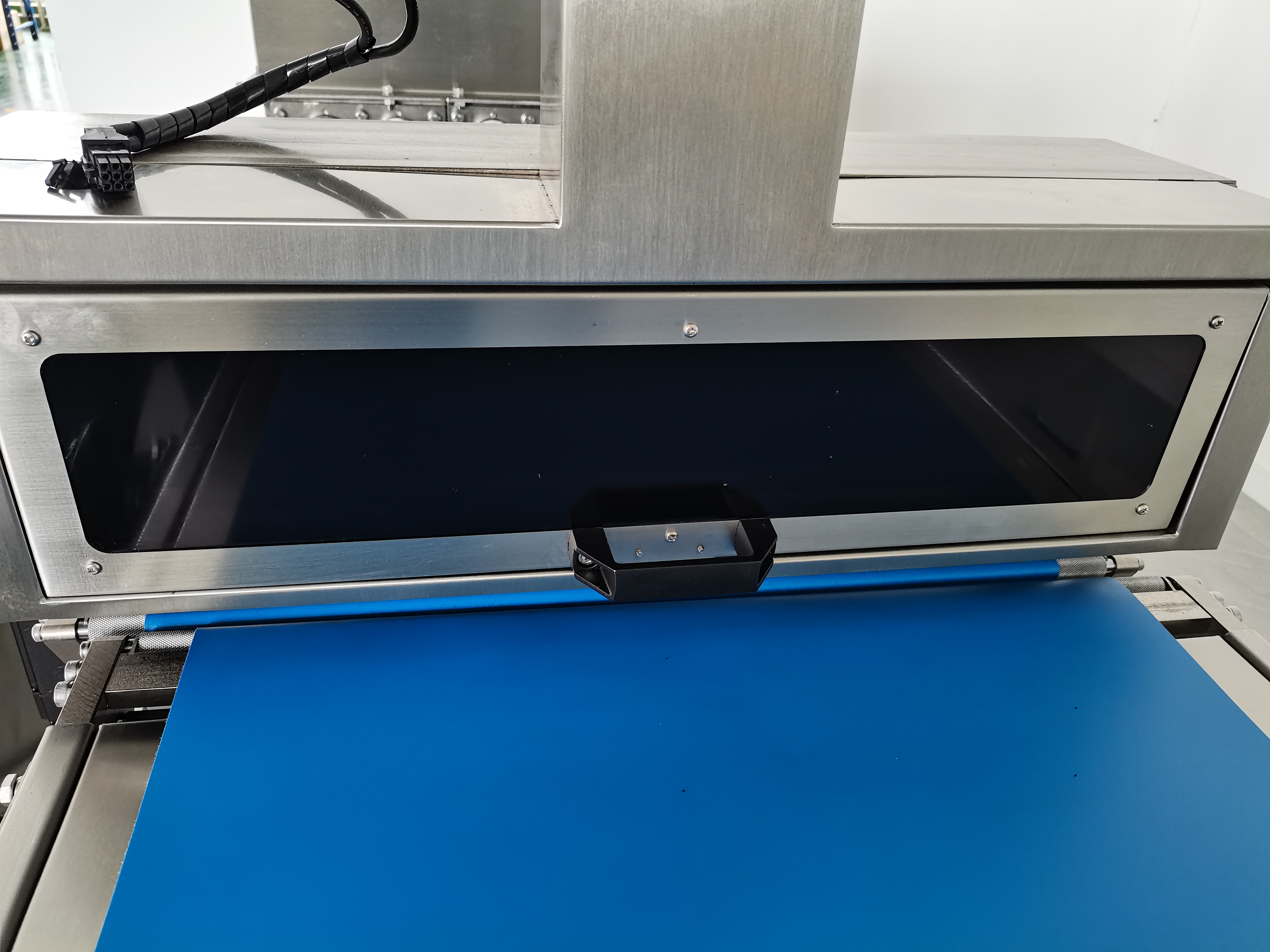

High-Performance and Advanced Control System

Equipped with a PLC-controlled touch screen, the P400 Protein Bar Extruder offers precise adjustment options for controlling production parameters like extrusion speed and cutting frequency. Capable of producing 240 to 480 bars per minute, it is designed for large-scale output. Its 304 stainless steel frame ensures reliability and long-term performance, with all components engineered for durability.

Product Features

Multi-row design: Capable of producing various bar shapes, from traditional rods to unique pyramids and discs.

High-speed production: Outputs between 240-480 bars per minute, suitable for high-demand production environments.

Durable 304 stainless steel construction: Ensures longevity and resistance to wear and tear in food production.

User-friendly PLC control: Simplifies the adjustment of speed, cutting, and other production settings through a touch screen interface.

Seamless integration: Works well with cooling tunnels, automated packaging machines, and other equipment to create a complete production line.

Multiple lanes protein bar production line for trapezoid shape bar machine video :

more Protein bite/energy bite video :

The high-capacity multi-row protein bar, date bar, and fruit bar making machine operate in conjunction with a flow packing machine to streamline the packaging process.

The automatic flow packing system handles tasks such as bar sorting, prefeeding, and automated packing. This system incorporates features like bar counting, sorting, and packing without the need for manual intervention, making it a fully automated solution. By eliminating the need for manual labor, this system significantly enhances efficiency and productivity, ultimately saving valuable time and labor resources.

FAQs

Q: Can this machine produce multiple bar shapes?

A: Yes, the P400 is highly versatile and can produce different shapes, including rods, discs, and pyramids.

Q: Does this machine support both soft and hard mixtures?

A: Yes, the P400 is designed to handle a variety of dough consistencies, from soft to firm.

Q: Can it be used with automated packaging equipment?

A: Yes, it can be integrated with flow packing machines for fully automated packaging solutions.