Description

Introducing the P307 Generation 4 Protein Bar Machine by PAPA—the pinnacle of versatility and efficiency in bar production technology. This state-of-the-art Protein Bar Machine is designed to accommodate a wide range of products, ensuring precise and customizable production tailored to your specific needs. Experience enhanced productivity and exceptional quality in your food manufacturing operations.

Protein bar Machinery specification

Model | P307 Generation 4 type |

Output/capacity | 40-80pcs/min |

Product weight | 10-250g |

Power | 1 kw |

Voltage | 220V single phase/380V three phase |

Dimension | L181*W50*H136cm |

Weight | 220kg |

Material | 304 stainless |

Mould material | PU |

Conveyor | PE |

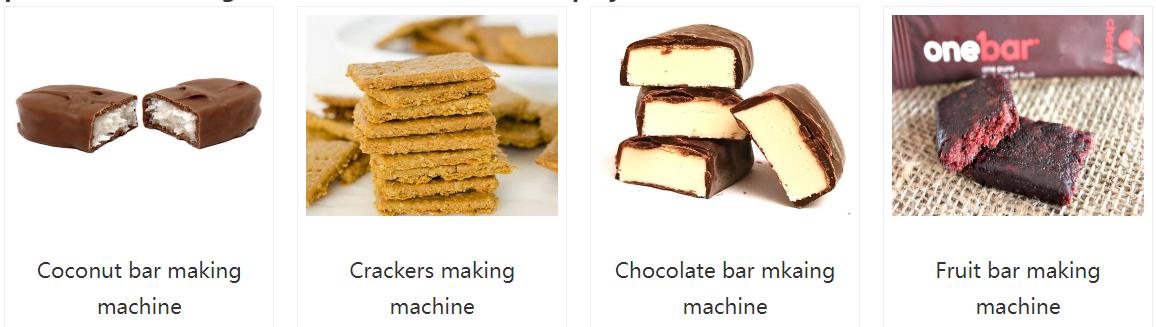

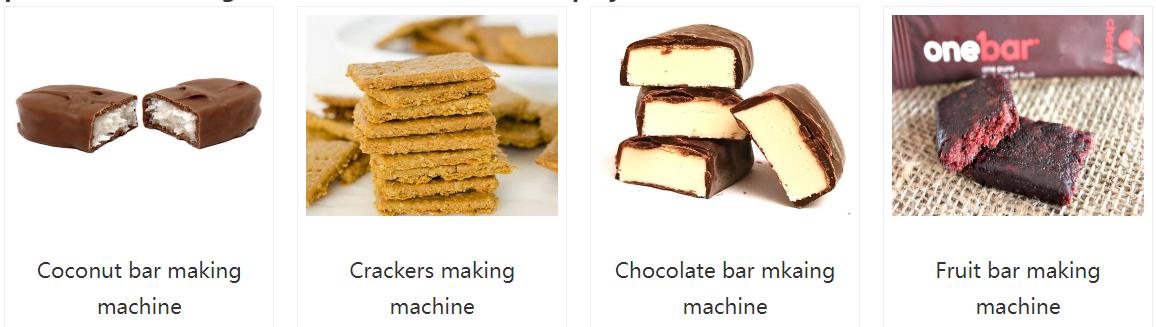

Application for P307 Automatic bar extruder machine

Key Features

Automatic Operation:

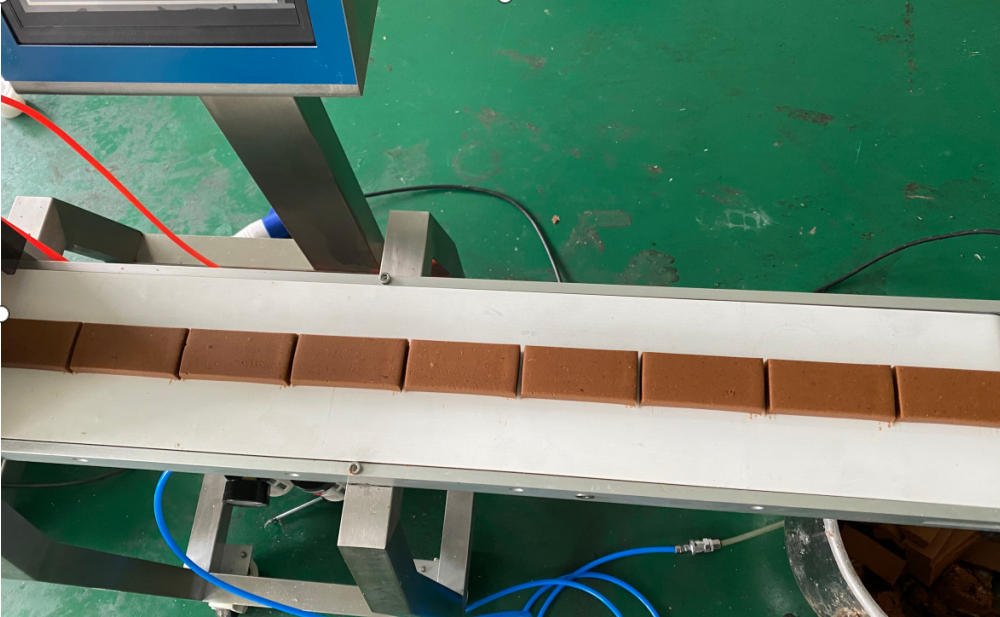

Experience seamless production with our fully automatic machine, capable of extruding bars with adjustable skin thickness, length, and size. The P307 Generation 4 type Automatic and Customizable Protein Bar Machine for Making Various Bars and Cookies streamlines your manufacturing process, increasing output and efficiency.

Customizable Molds:

Easily switch between different molds to create a variety of bar types and sizes, including protein bars, date bars, energy bars, and more. The flexibility of this Protein Bar Machine allows you to adapt your production line to meet market demands effortlessly.

Versatile Production:

This machine is ideal for producing diverse products such as coconut bars, crackers, chocolate bars, fruit bars, and cookies. The ability to handle various dough types—soft, sticky, and semi-soft—makes it an invaluable asset for any bakery or food production facility.

Professional Quality:

Constructed from food-grade materials, the P307 Generation 4 Protein Bar Machine ensures high safety standards and hygiene for your production line. Trust in the quality and reliability of a machine designed for professional use.

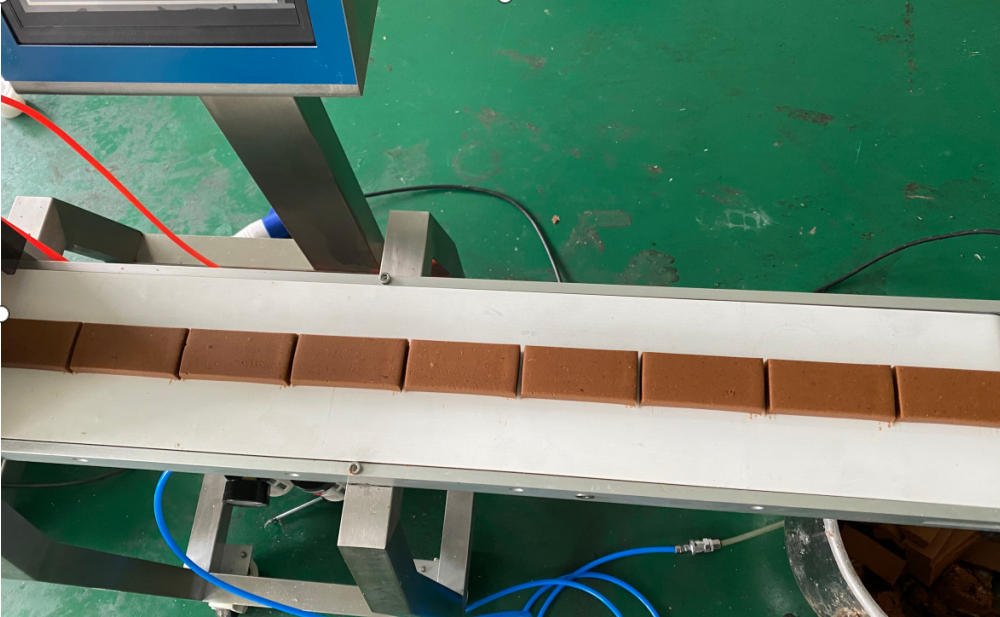

Advanced Cutting System:

Equipped with a carbon steel cutting blade featuring a Teflon coating for accurate and efficient cutting. The PLC-controlled system allows easy speed adjustments via a user-friendly touch screen panel, providing precise control over your production process.

Safety First:

Safety features include guards and covers for a secure operating environment. The adjustable conveyor belt speed accommodates different bar sizes, ensuring a safe and efficient workflow.

Double Layer Production:

This versatile machine is capable of creating double-layer protein bars, including those with granule toppings, enhancing your product offerings and meeting diverse customer preferences.

If you wanna to produce double layer protein bar , PAPA machine also can do it .

Granules sprinkled double layer food energy bar making machine video

Date bar making machine working video :

How to Maintain the P307 Protein Bar Machine

To ensure optimal performance and longevity of your P307 Generation 4 Protein Bar Machine, follow these maintenance tips:

Regular Cleaning:

Clean the machine daily after production. Use food-safe cleaning agents to prevent contamination and maintain hygiene. Pay special attention to the extruding head and cutting blades.

Lubrication:

Regularly lubricate moving parts according to the manufacturer's recommendations. This prevents wear and tear and ensures smooth operation.

Inspection:

Periodically inspect the machine for any signs of wear or damage. Check the cutting blades for sharpness and replace them as needed to maintain cutting efficiency.

Calibration:

Regularly calibrate the machine settings to ensure accurate production. This includes adjusting the mold settings and cutting speed as necessary.

Operator Training:

Ensure all operators are trained in the proper use and maintenance of the machine. Understanding how to operate the machine safely and effectively will enhance productivity and reduce the risk of accidents.

By following these maintenance tips, you can maximize the efficiency and lifespan of your P307 Protein Bar Machine, ensuring consistent and high-quality production of various bars and cookies.

FAQs

Q1: What types of bars can this machine make?

A1: The P307 Generation 4 Protein Bar Machine can produce a wide range of products, including protein bars, date bars, energy bars, fruit bars, coconut bars, chocolate bars, crackers, and cookies.

Q2: Can the machine handle different sizes and shapes of bars?

A2: Yes, the machine features customizable molds and adjustable settings to produce bars in various shapes and sizes, such as spheres, circles, rectangles, and cylinders.

Q3: How do I adjust the thickness and size of the bars?

A3: The machine allows for easy adjustments in skin thickness, length, and size through its automated settings and interchangeable molds.

Q4: Is the machine safe to operate?

A4: Yes, it is equipped with multiple safety features, including safety guards, a protective conveyor cover, and easy-to-clean components to ensure operator safety and maintain hygiene.

Q5: Can the machine produce double-layer bars?

A5: Absolutely. The P307 can create double-layer protein bars, including those with granules or other toppings.

Q6: What maintenance is required for the machine?

A6: Regular maintenance includes cleaning the cutting blade, checking the conveyor system, and ensuring all safety features are in place. The machine is designed for straightforward cleaning and upkeep.

Q7: How does the PLC control system work?

A7: The PLC control system allows for precise control of cutting speed and other machine settings via a touch screen panel, making adjustments simple and efficient.

For more information or to request a quote, please contact PAPA. Upgrade your production capabilities with the P307 Generation 4 Protein Bar Machine today!