Description

The Papa P308 Protein Bar Making Machine is engineered for maximum efficiency in producing a wide range of bars and cookies. With a powerful 380V three-phase motor and robust 304 stainless steel construction, it can handle tough, dry mixtures with ease. This machine addresses common extrusion challenges, making it an ideal choice for manufacturers looking to create diverse products such as protein bars, date bars, and chocolate-coated snacks. Its versatility allows for customization in bar size and thickness, making it suitable for various production needs.

Overview of Papa P308

The Papa P308 Protein Bar Making Machine is designed for manufacturers who need a reliable solution for creating a variety of hard and dry food bars. This advanced extruding machine is perfect for producing not just protein bars but also energy bars, date bars, and a wide range of other snack products. Its robust design ensures that it can handle tough ingredients, making it an essential addition to any production facility.

Efficient Extrusion Technology

One of the standout features of the Papa P308 is its powerful 380V three-phase motor, which delivers exceptional torque. This capability ensures that the machine can effectively extrude hard mixtures that would typically pose challenges for other machines. The full 304 stainless steel construction further enhances durability and hygiene, making it ideal for food production.

Customization and Versatility

The P308 model allows for significant customization in bar production. Users can easily adjust the thickness, length, and size of the bars, accommodating a variety of product specifications. Additionally, the machine supports interchangeable molds, allowing for the creation of different bar shapes and sizes with minimal downtime. It can also integrate seamlessly with other food processing equipment, such as cooling tunnels and packing machines, enabling a smooth and efficient production line.

Specification :

Model | P308 |

Output/capacity | 40-80pcs/min |

Product weight | 10-250g |

Power | 4 kw |

Voltage | 380V three phase |

Dimension | 2550*760*1400mm |

Weight | 250kg |

Material | 304 stainless |

Mould material | PU |

Conveyor | PE |

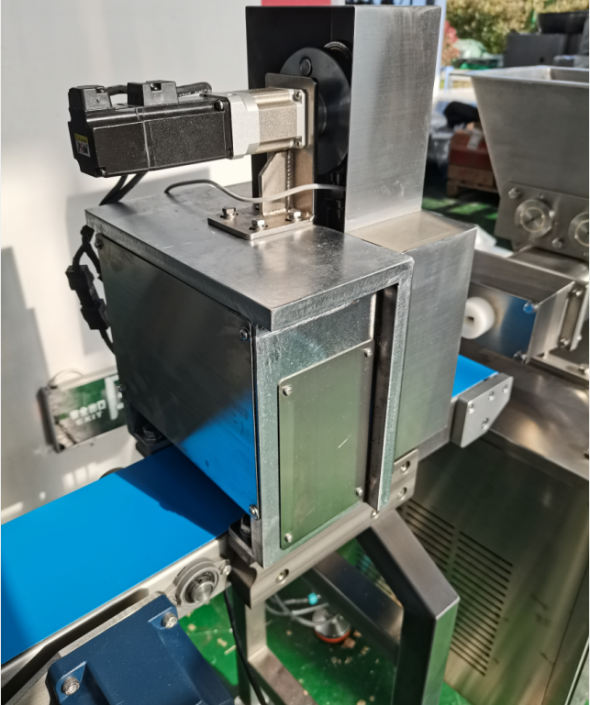

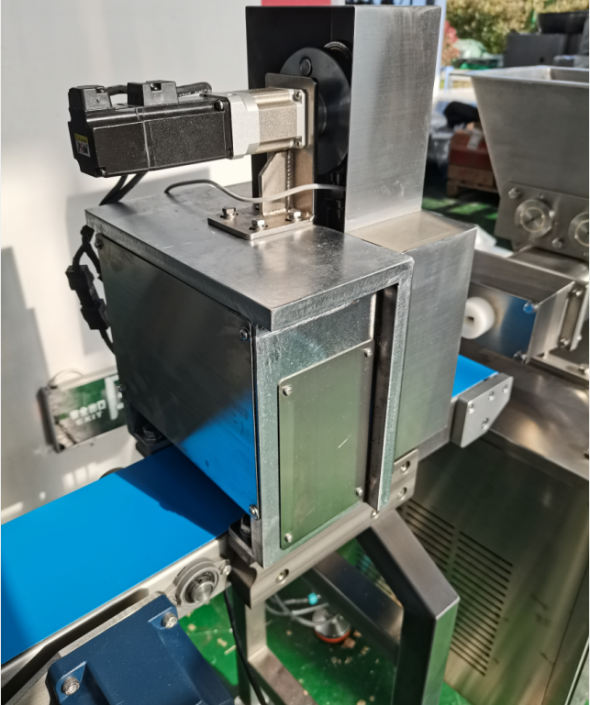

Automatic servo cutter with conveyor(PLC control) features:

* Carbon steel cutting blade with teflon coated, suitable for cutting various bars.

* Pressing roller in front of the cutting blade help to stable the bar and anti-sticking.

* Safety guard around cutter see through inside, easy to remove and clean.

* Speed easy to control by changing numbers in the touch screen panel.

* Safety cover along the conveyor belt makes sure safety in production.

* Conveyor speed adjustable according to bar size.

* Updated to Servo cutter, No need connect air compressor

which reduces the noise in the factory and makes cutting faster,more stable and accurate

Protein bar extruder features:

* Machine body & Hopper made by 304 Stainless steel.

* Custom designed nozzle make different size bars.

* Available to make multiple rows at one time, not only suitable for small capacity business usage,

but also in big capacity business.

* Extruder and cutter separately design makes the machine easy for cleaning and .

* Machine completely packed and sent before shipment, no need installation, just connect electricity.

* Automatic control, just changing numbers on screen.

The P308 powerful protein bar extruder work with flow wrapping machine .

PA250 Automatic flow wrapping machine for protein bar packing :

this flow wrapping machine can wrap protein bar ,date bar, energy bar ,fruit bar , cereal bar ,granolar bar and so on .

chocolate bar making machine working video :

Specifications and technical parameters |

Packing speed (bag/min) | 35-150

|

Packaging film width (mm) | 90-240

|

Bag size (mm) | Length(flat bag) | 85-300

|

Width | 30-100

|

Height | 5-30

|

Total power (kw) | 3.0

|

Main motor power (kw) | 0.75+0.75

|

Heating power (kw) | 1.2

|

Machine net weight (kg) | 600

|

Machine dimensions (length * width * height) (mm) | 1640×830×1350

|

Machine noise (dB) | ≤78dB

|

Qualified rate of bagging (percentage) | ≥98%

|

Sealing pressure (Newton/mm2) | 15

|

Voltage | 220V 50Hz |

Packaging film material | OPP、PE、PVC、OPP/CPP、PT/PE、KOP/CPP、Aluminum film etc.。 |

FAQs

1. What types of bars can the P308 machine produce?

The P308 can produce protein bars, energy bars, date bars, fruit bars, chocolate bars, and more.

2. What motor does the P308 use?

3. Is the machine suitable for hard ingredients?

4. Can the P308 be used with other machines?

Absolutely! It can be combined with cooling tunnels, chocolate enrobers, packing machines, and ovens.

5. What materials are used in the construction of the machine?

6. How does the machine allow for customization?

Users can adjust the skin thickness, length, and size of the bars, and use interchangeable molds for different shapes.