Product Description

1. High-Efficiency Production Process

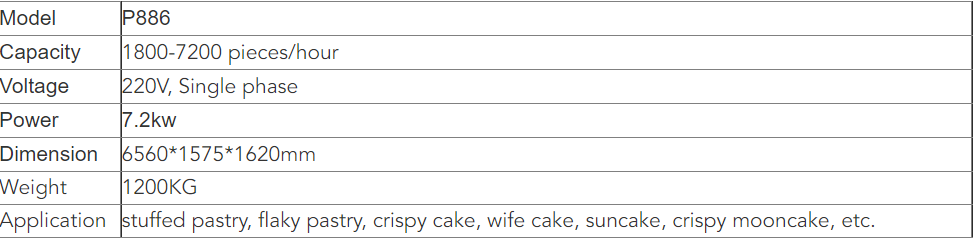

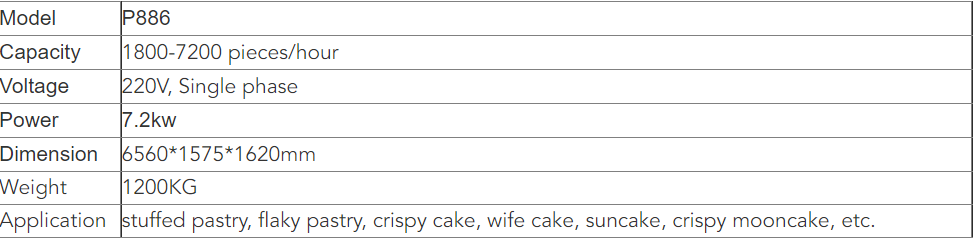

The Egg Yolk Crisp Production Line is engineered to streamline the entire production process. It includes advanced components such as the P886 3 Roller Pressing Machine, which ensures consistent dough quality through multiple pressing stages. The Automatic Encrusting Machine allows for precision filling, while the Pinching Cutter Machine guarantees accurate closure and shaping of the pastry.

2. Versatile Machinery for Various Pastries

This production line is not limited to egg yolk crisps alone. With its adaptable design, it can also produce an array of flaky pastries, including wife cake, puff pastry, meat pies, suncake, and durian cakes. Additional components, such as the Tray Arranging Machine, make the process even more efficient by ensuring consistent product alignment for packaging.

3. Precision and Control

Every machine in the Egg Yolk Crisp Production Line is built for precision. The Dough Thickness Adjustment feature allows operators to fine-tune the dough’s thickness, ensuring product consistency. With Dough Conveying Systems that regulate speed, the risk of dough tearing or breaking is minimized. The line is further enhanced with devices for Egg Straying and Sesame Sprinkling, making it ideal for producing premium, visually appealing pastries.

Product Features

P886 3 Roller Pressing Machine: Ensures multi-stage dough pressing and shaping for a fine, even finish.

Automatic Encrusting Machine: Accurately fills and shapes pastries with precise control, ensuring consistent quality.

Pinching Cutter Machine: Provides exact closure and cutting for a wide variety of pastries.

Dough Thickness Adjustment: Allows fine-tuning of dough thickness to achieve the desired product weight and texture.

Tray Arranging Machine: Ensures organized and efficient product placement for streamlined packaging.

Egg Straying & Sesame Sprinkling: Enhances product appearance and adds value with finishing touches.

Egg Yolk stuffed flaky pastry production line picture :

Durian cake production line picture :

Flaky pastry produced by P886 Flaky pastry production line Application:

Optional device:

1. Blade type cutter machine

The blade type cutter machine is used for cutting bread or steamed buns. The vertial cutting machine is separated control and easy to move in the crispy pastry production line.

2. Pinching type cutter machine (nine knives)

The pinching type cutter machine has nine knives shutter to form steamed stuffed buns , egg yolk stuffed in the stuffed cake production line. It can be added as an optional equipment in this flaky pastry line to make egg yolk crispy .

3. Sesame sprinkler and yolk brusher

The sesame sprinkler and yolk brusher is used for bread top seame sprinkling and yolk brushing. It is mainly used for bread rolls and buns. Automatic sprinking sesame on food top ,to make the produccts shiny and more delicious ,and save large labor cost and time .

4. Puff pastry dough sheeting machine

The puff pastry dough sheeting machine is used in the puff pastry production line for making cripsy sheet, the dough sheeting machine continuous roll the dough back and forth to be strenched to reach paper-thin dough.

5. Dough presser

The dough presser is used for bread dough kneading and pressing before going to the three roller bread forming machine. The automatic dough presser replaces manual kneading to save labor power and time.

6. Tray arranging machine

Fully automatic arranging machine is suitable for food enterprises of scale production, it could pick up products in the baking trays directly. It can avoid the destruction or contamination by hand before the product is not baked, and can reach food hygiene standards.

The automatic tray arranging machine is used in the bread production line to collect the final formed bread,It will automatically drop the bread into baking trays uniformly one by one with distance. The tray arranging machine can also be used in other food production line to collect other food.

How to Maintain

Regularly clean all machines, especially the pressing wheels and filling components to avoid residue build-up.

Lubricate moving parts as needed to ensure smooth operation and prevent wear.

Inspect the electrical systems and sensors regularly to maintain optimal speed and performance.

FAQs

Q1: Can the line produce different pastries aside from egg yolk crisps?

A1: Yes, the line is versatile and can produce a wide range of pastries such as puff pastries, wife cakes, and meat pies.

Q2: How can I adjust the dough thickness?

A2: The P886 3 Roller Pressing Machine includes a thickness adjustment device that allows you to customize the dough thickness according to your needs.

Q3: Is the line easy to clean?

A3: Yes, the production line is designed for easy disassembly and cleaning, ensuring hygiene and reducing downtime.

By incorporating Papa Food Machine's innovative technology, the Egg Yolk Crisp Production Line offers a reliable solution for businesses aiming to produce high-quality, mass-produced pastries with ease and precision.