Description :

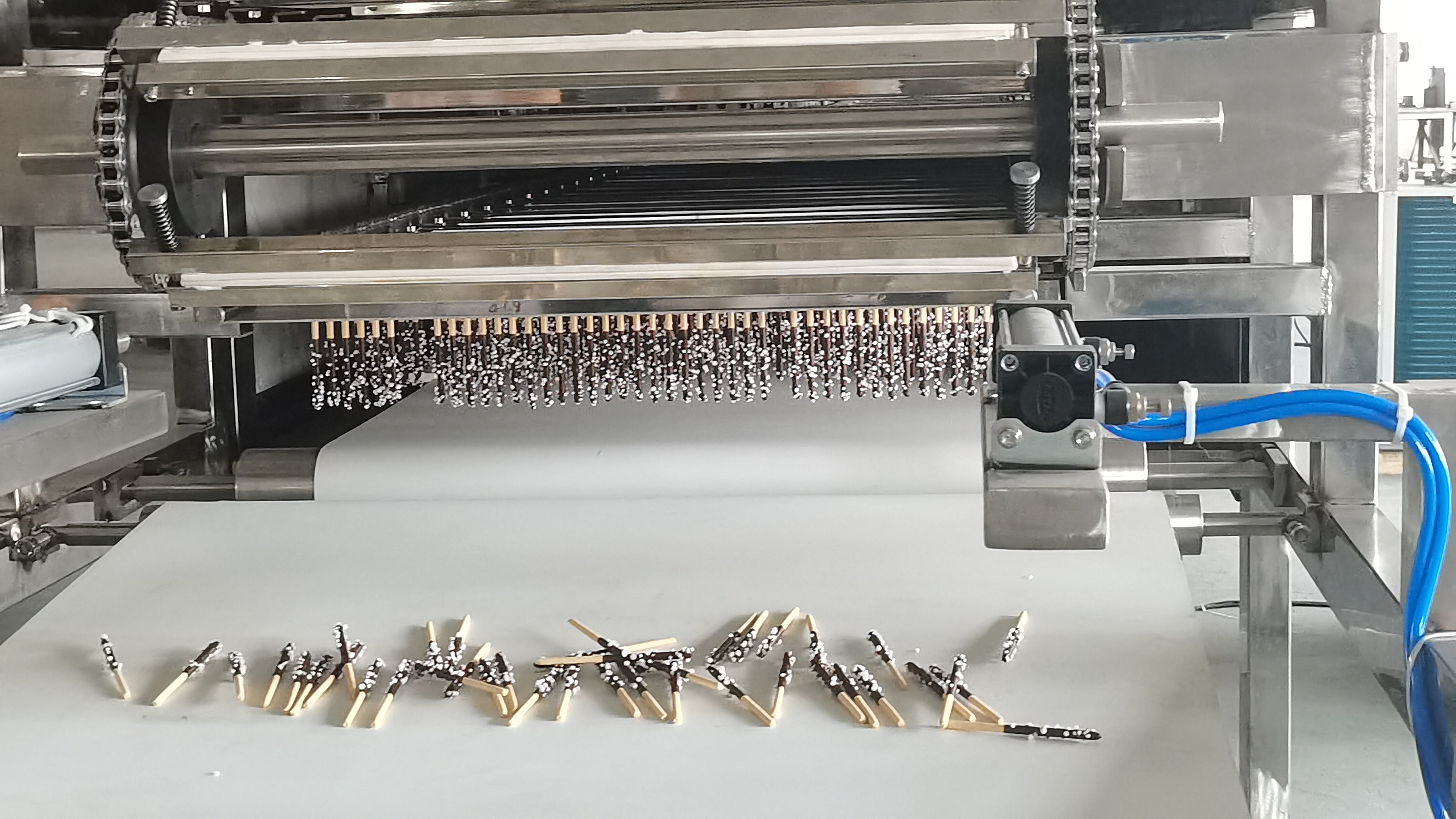

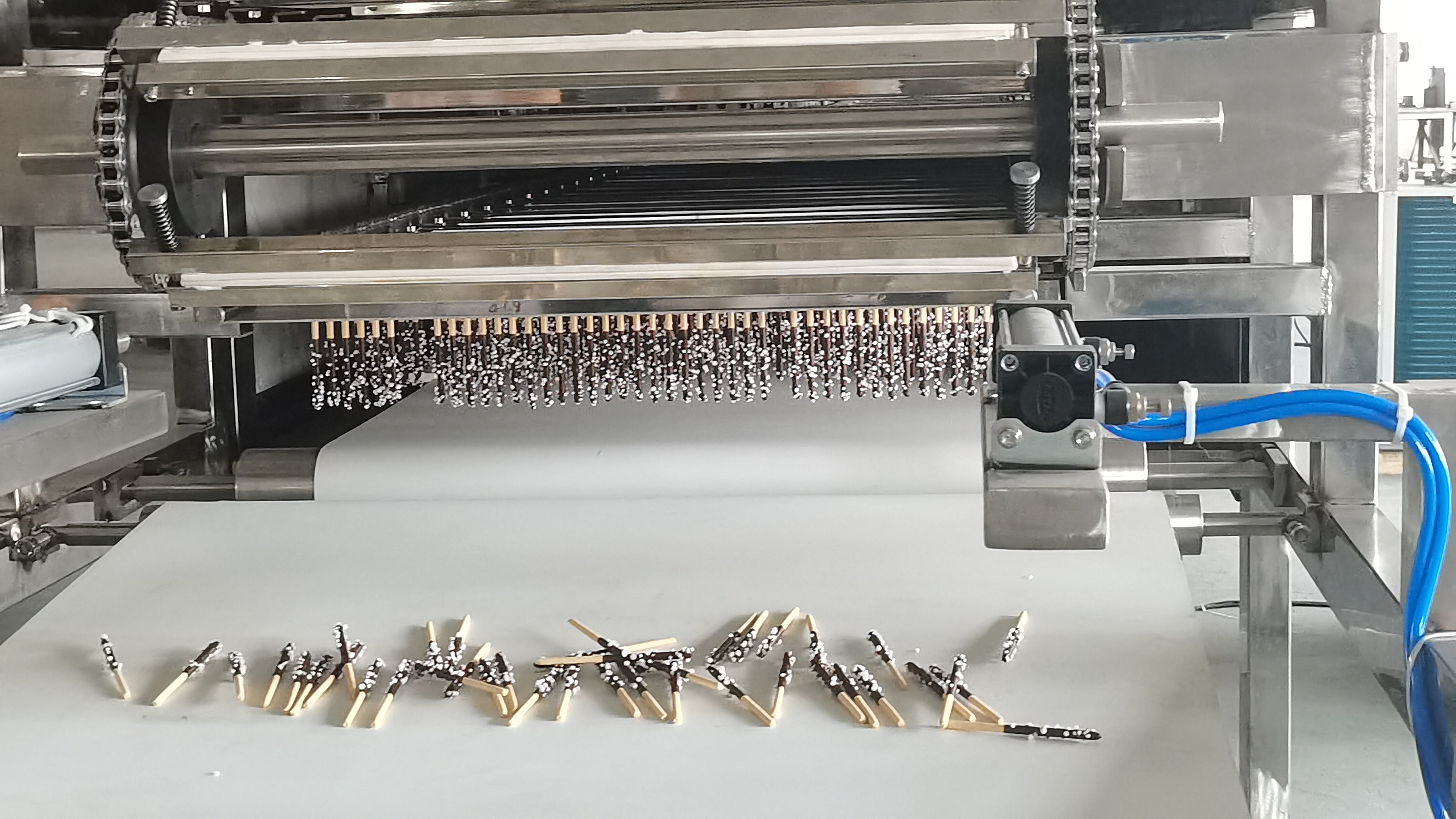

This machine is designed for coating biscuit sticks with various materials like milk, cream, chocolate, or jams to create different flavors. The process begins with manually feeding baked biscuit sticks into a hopper, where they are then placed into molds and fixed in place. The sticks are then pushed downwards by a device, moving through the machine where they are coated with chocolate or other coatings. The machine automates the process significantly, enhancing product quality, safety, and efficiency.

Operating on electric, gas, and photoelectric tracking control systems, this machine ensures a high level of automation, maintaining a consistent coating thickness and a visually appealing finish. After the initial coating, granules can be added, followed by a brief cooling period before a second coating is applied. The biscuit sticks are then cooled in a tunnel, ready for packaging.

Specification :

Model | 900 |

Wire mesh and belt width(mm) | 900 |

Wire mesh and belt speed (m/min) | 1-10 |

Refrigeration unit(set) | 5P -3sets |

Cooling tunnel lenth(m) | 20 |

Cooling tunnel temperature (°C) | 2-10 |

Total power(kw ) | 23.8 |

Weight(kg) | 3400 |

Dimension(mm) | 24200*1450*1800 |