Product Introduction

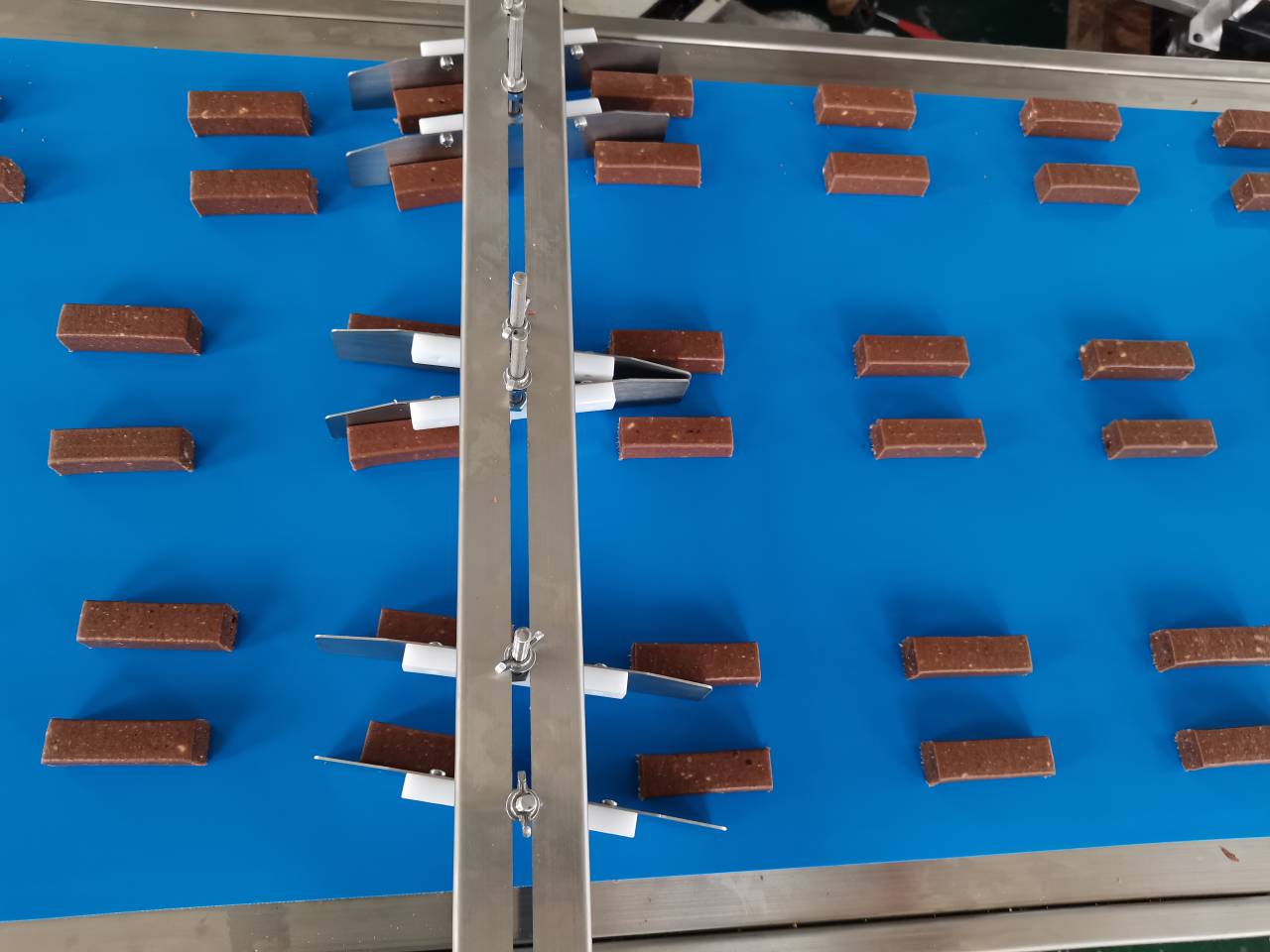

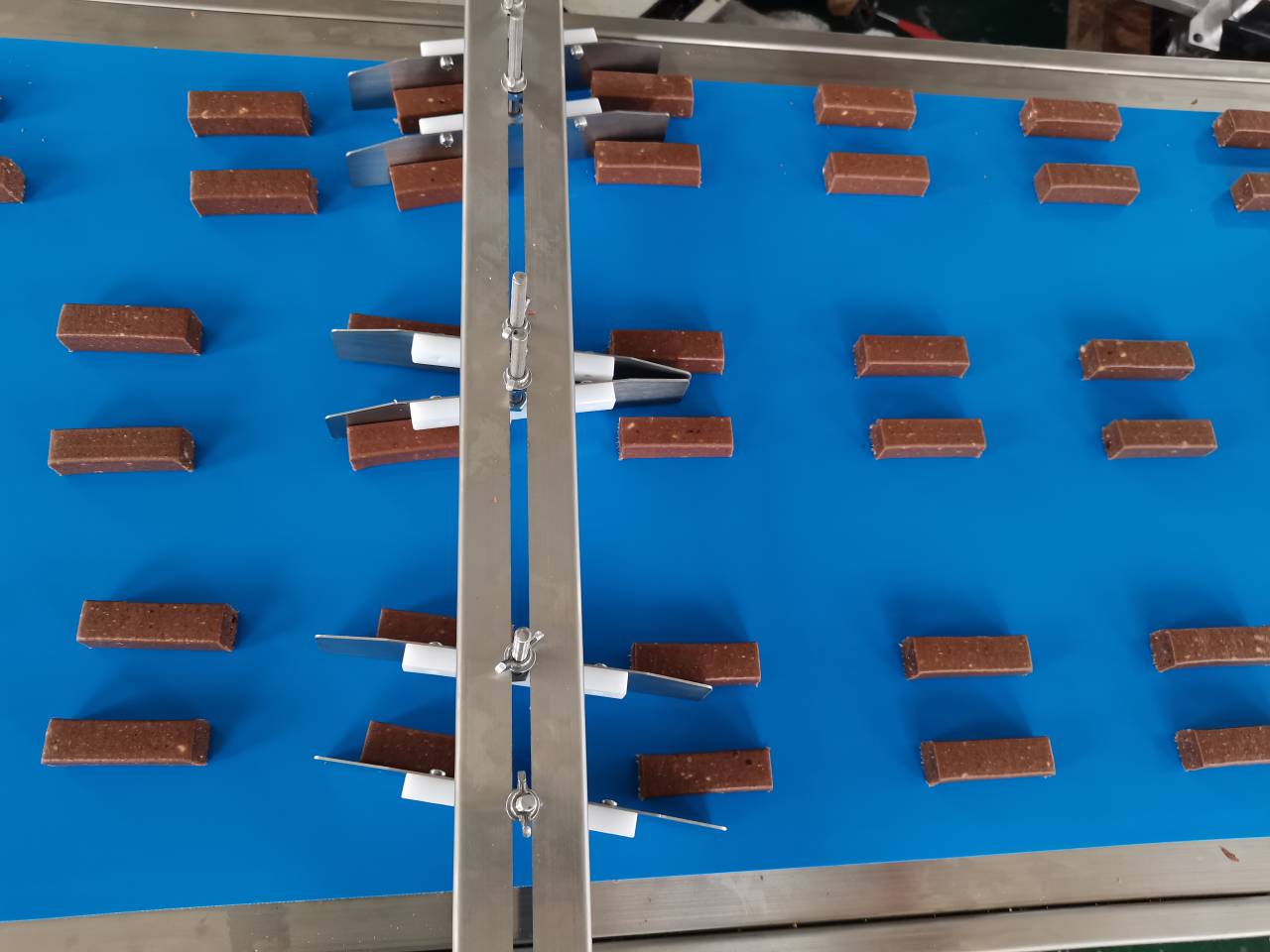

The Papa fully automatic P400 multi-row protein energy bar production line is specifically designed to meet the high productivity needs of customers seeking to produce soft or hard energy bar foods. The production line consists of a protein bar extruder, a cutter with a conveyor. The protein bar extruder is responsible for shaping the bars to the desired size, while the cutter is used to cut the bars to the desired length.

The production line features a servo motor with a touch panel, ensuring precise control and easy operation. The knife used in the cutter is coated with Teflon, minimizing sticking and ensuring clean cuts. The push bar is driven by a servo motor, allowing for continuous operation and the ability to set the desired bar length for cutting.

Automatic encrusting and forming machine is mainly designed for customers who have high productivity requirements for soft or hard protein bar foods. Our newly upgraded P400 multi channel energy bar production machine has a productivity of 240-480 per minute.

The conveyor belt can be customized made into 400mm , 600mm width . then will be match with chocolate coating enrober machine to making chocolate protein bars .

Multiple lanes protein bar production line for trapezoid shape bar machine video :

more Protein bite/energy bite video :

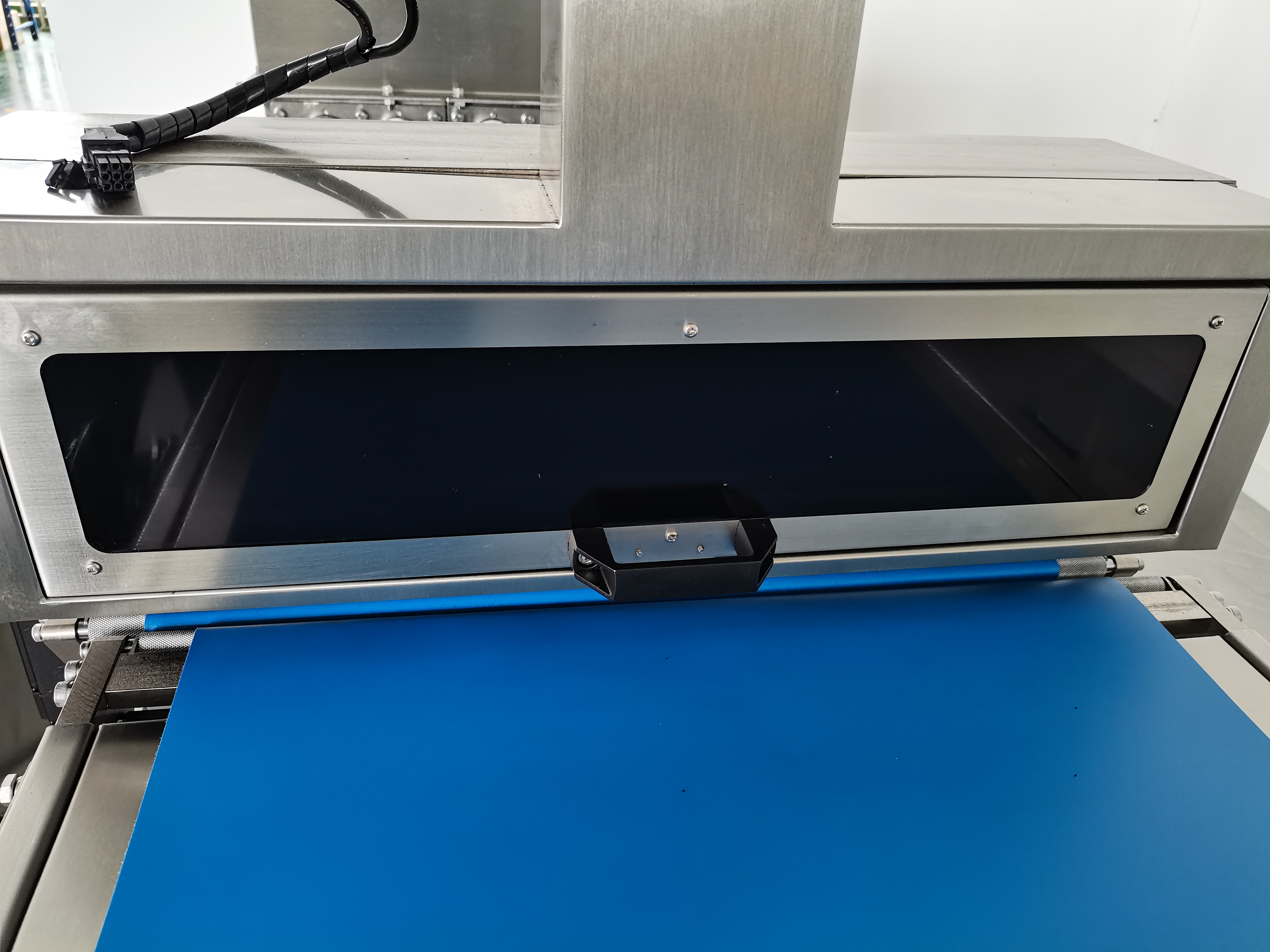

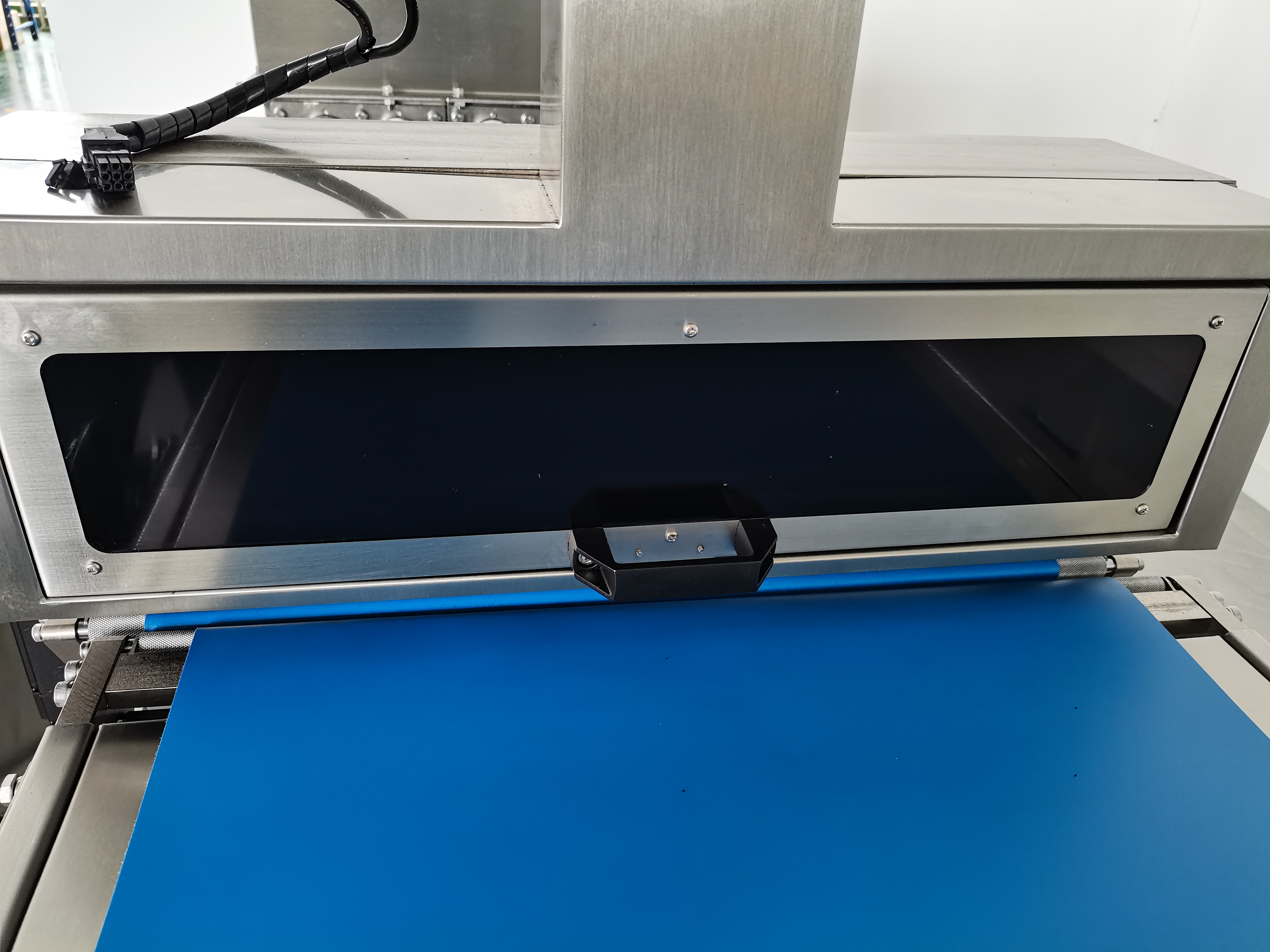

400/600mm Chocolate coating machine with cooling tunnel .

Chocolate Enrobing Enrober Machine With Factory Price for biscuit is to coat chocolate on various food such as cereal bars, energy bars, protein bars, candy bars, rice bites, wafers and wafer stick, birthday cakes, cakes, breads, rolls, pies, muffins, snacks, candies, confectionery, maamoul and mooncakes, cookies, biscuits, crackers, cake ball, date ball and chocolate truffles, mochi, dates for whole coating, single-sided coating, partial coating and cooling.

multirow protein bar machine work with packing machine .