Product Description

The P180 Automatic Encrusting Machine is designed to revolutionize food production with its high-speed operation and tray arrangement capability. With PLC control, customizable tray alignment, and a three-hopper upgrade, this machine efficiently produces a wide variety of stuffed and double-color foods. Ideal for producing mochi, cookies, and soft cakes, the P180 delivers top-tier performance and precision.

1. High-Speed Production with Tray Arranger

The P180 Automatic Encrusting Machine integrates a tray arranger for seamless food production and packaging. With a speed of up to 100 pieces per minute, this machine is perfect for high-demand environments. Its PLC-controlled system ensures precise operation, making it an indispensable asset for manufacturers focused on mochi, cookies, and other stuffed food products. The tray alignment can be customized, providing flexibility to suit different tray sizes.

2. Multi-Functional and Space-Saving Design

Designed with efficiency in mind, the P180 combines multiple functions in one compact machine. It can handle a variety of food items like ice cream mochi, soft cakes, daifuku, and more. The machine's three-hopper system allows for the creation of double-color fillings and multi-flavor products. Additionally, its space-saving design makes it ideal for businesses that require high performance without sacrificing valuable production space.

3. Precise and Customizable Operation

Equipped with a touch screen control panel, the P180 Encrusting Machine allows for easy adjustments and storage of production settings. This enables the production of different food sizes and shapes with precision. The machine's hopper can be customized to suit the unique production needs of each customer, providing flexibility in handling sticky foods and other specialized recipes.

Papa Food Machine's dedication to quality ensures that the P180 is built with reliable components, guaranteeing long-lasting performance for any food manufacturer.

Features of Automatic mochi making machine

Tray Arranger Integration: Automatically aligns products onto trays, saving labor and improving efficiency.

Three-Hopper System: Capable of producing double-color fillings and multiple food varieties.

Touch Screen Control: Easy to use and adjust, with parameters that can be stored for future use.

High-Speed Production: Up to 100 pcs/min, ideal for high-volume manufacturing.

PLC Control System: Ensures precision and reliability in production.

Customizable Tray Alignment: Tray sizes can be customized to meet different production requirements.

Multi-Functionality: Produces a wide range of products, including mochi, cookies, soft cakes, and stuffed foods.

How to Use

Power On: Connect to the power supply and turn on the machine.

Loading Ingredients: Fill the hoppers with dough and filling materials.

Adjust Settings: Use the touch screen to adjust the filling quantity, speed, and tray alignment.

Start Production: Begin automated encrusting and tray arranging for continuous production.

How to Maintain

Regular Cleaning: Clean hoppers, nozzles, and conveyor belts after each use.

Lubrication: Ensure all moving parts are properly lubricated to prevent wear.

Inspection: Periodically check the machine for any wear and tear, especially on critical components like the hopper and tray aligning system.

Application: Japanese Daifuku, Thai moji, mochi, mochi ice cream, kubba, coxinha, falafel, filled donut, meat ball, stuffed bun, filled cookies, crystal bun and so on.

Specifications for ice cream mochi making machine:

Model | P180 |

Capacity | 60-100pcs/min |

Product shape | Ball, cone, round strip, side square, terraced , serrate and etc |

Product weight | 10-100g |

Casing and filling proportion | 1:9-10:0 |

Power | 3.5kw |

Motor brand | TAIWAN LIMING ,SIEMENS,GERMANY |

Voltage | 220v/50hz |

Dimension | 1900x1120x1130mm |

Weight | 320kg |

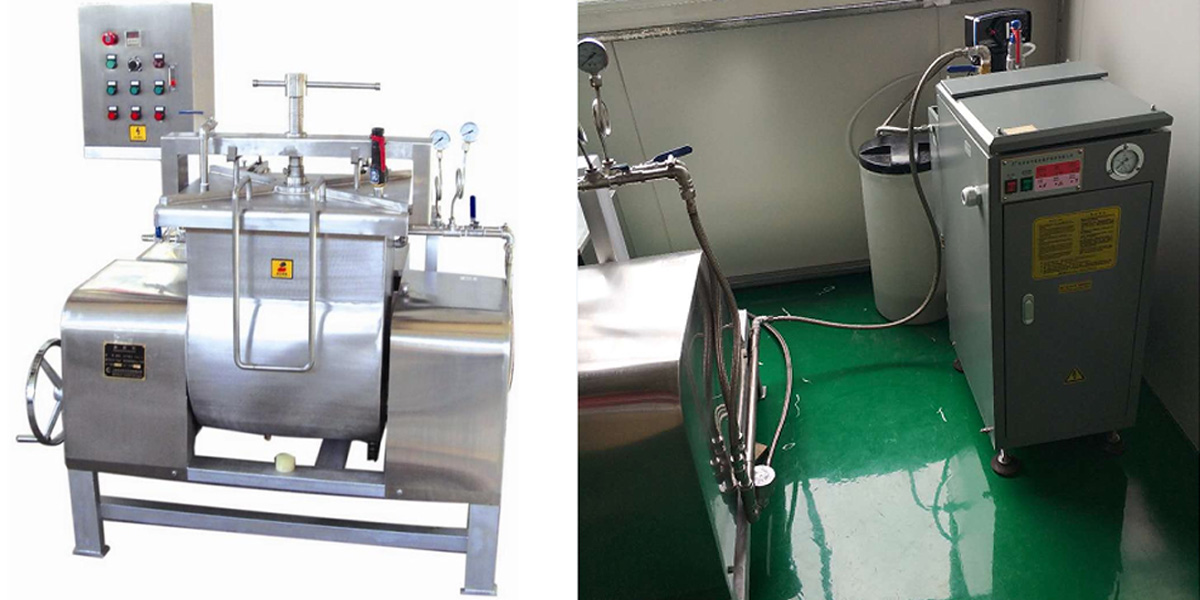

Evaporate mixing machine Technology parameter

Machine dimension: 155*120*160cm

Machine weight: 650kg

Power: 4kw

Capacity: 60L/h

Rotation: 15-45times/ min

Vapour pressure: MPa

Function: Make the dough, Mixing and steaming food

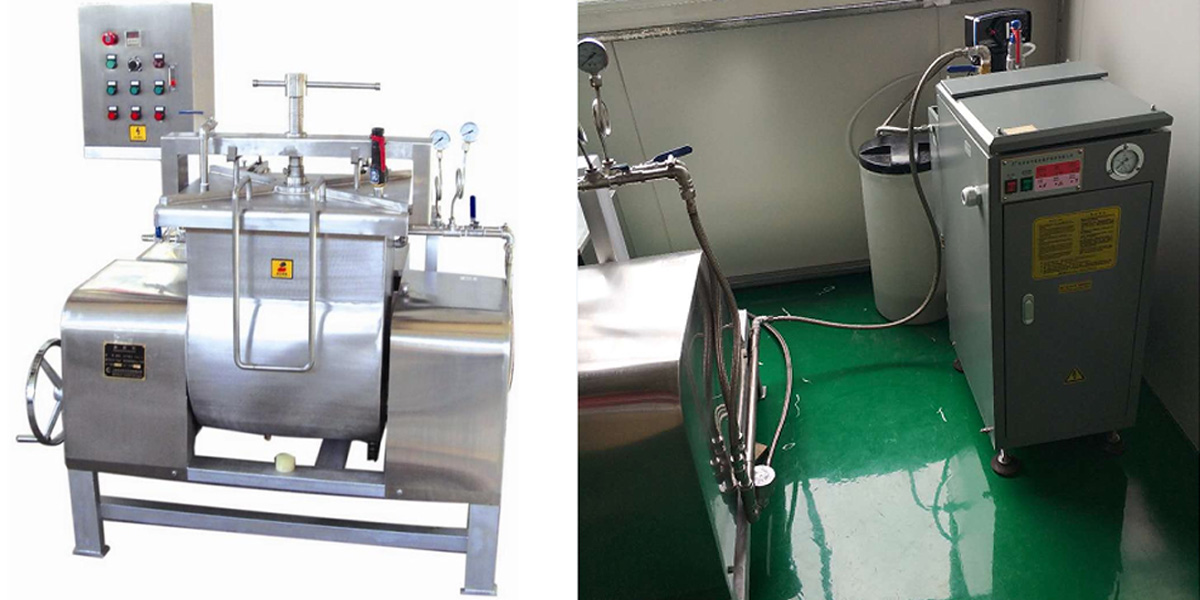

Steam generator with water softener

Main parameter

Dimension: 66*40*110cm

Weight: 80kg

Power: 24kw

Voltage: 380v

Working pressure: 0.7MPa

Evaporation capacity: 30kg/h

Function: Make the water into steam.

Why choose US

Substantial Experience

Papa Food Machine has over 16 years of expertise in the food equipment manufacturing industry. Our equipment is trusted by customers in over 100 countries, ensuring top-notch quality and performance.

Professional Technical Team

Our engineers are skilled in installation, debugging, and training. We provide continuous technical support to ensure smooth operation, with professionals available globally.

Excellent Sales Team

Our team is known for delivering complete project proposals, offering personalized solutions that fit every client's needs. We respond to inquiries promptly, ensuring excellent communication and service.

Reasonable Pricing and Superior Quality

Papa Food Machine offers the most cost-effective equipment without compromising on quality. We incorporate premium components like Taiwanese Liming motors and Delta PLC systems, ensuring long-term reliability.

Quality Guarantee

We provide a 12-month warranty and lifetime service for all our machines, ensuring that your investment is protected.

OEM / ODM Order Available

Reliable Machinery has the experience, capability, and professional R&D team to make any OEM/ODM customers' project! Responsible workshop management follow up and supervise each order.

Free Customized Designs

Reliable Machinery have our own engineers and designers to give you professional suggestions for selecting site, building factory, choosing products and so on. We offer you A to Z turnkey projects. You only give us your idea, we will offer you perfect factory design, hydropower layout design, Logo design, label design, food formulation, etc. Guarantee customers get most favorite products.

After-sales Service Guarantee

1. We will provide the complete customs clearance documents on time to make sure you can take delivery of machines quickly.

2. Our engineers will go to your factory to install and test machines, and train your employees until they can operate machines well.

3. We provide 12 months year warranty with spare parts for free start from shipping date.

4. All machines have life-long service.

Quality Guarantee

One year for parts guarantee. And in this year if the machine broken caused by mechanical problem, all of the spare part is free. The service of the machine all though the machine's life.

Others

Delivery Date: Within 25 days upon the receipt of the down payment.

Delivery: FOB Shanghai

Terms Of Payment: Before shipping, the seller should test running the machines for buyer’s inspection and do the shipping after all parts are inspected and accepted by the buyer, 50% should be paid by T/T as the deposit, 50% should be paid by T/T before shipping.

Notes: The quotation information just for customers to reference, Due to the company’s policy of continuous improvement, we has the right reserved to make technical modifications without prior notice.

Testing & training: The plant layout design, assembling and installation, start-up and local team training will be FREE at no cost. But the buyer should be responsible for the round-air tickets, local transportation, board & lodging, and US$100.-/day/person for the pocket money to our technicians. The testing people will be 1-2 persons, and will cost 3-10days.

Warranty: The seller guarantees the quality of the products for 12 months since the date of installation. During the warranty period, any problems/defaults happen on the hard parts of the machinery; the seller will replace the parts or send the technicians to go to the buyer’s site for repairing and maintenance at FREE. If the defaults are aroused by the defaulted operations of the buyer, or the buyer needs the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.

Validity: This offer is valid 30 days.

FAQs

What types of food can the P180 machine produce?

The P180 can handle a variety of products such as mochi, soft cakes, cookies, and stuffed foods like daifuku and filled quick-frozen products.

Can the machine handle sticky foods?

Yes, the machine comes with up and down dusters to ensure sticky foods do not stick to the tray or pan.

Is the tray arrangement customizable?

Absolutely, the tray arrangement system can be customized to fit different tray sizes according to your production requirements.

In case there are any questions concerning this quotation, please do not hesitate to contact undersigned. Thanks & Best regards!