Product Description

The P160 Date Ball Making Line is designed for producing uniform date balls, protein balls, and energy balls. With two hoppers for casing and center filling, it ensures precise shaping and filling. This machine integrates Date Ball Encrusting Machine P160, Small Ball Rounding Machine P110-1, and Coconut Date Ball Covering Machine P110-2 for a fully automatic production line. The Energy Ball Extruder guarantees accuracy in size and weight.

Versatile and Advanced Production Line

The P160 Date Ball Making Line is a state-of-the-art solution designed for producing a variety of energy-filled snacks, including date balls, protein balls, and more. This line integrates cutting-edge automation with precision crafting to ensure consistent, high-quality output. Equipped with a Two Hopper Ball Extruder, the machine allows for both filled and unfilled products, making it versatile for creating a broad range of healthy snack options.

The machine's PLC Control System and touch screen panel enable easy customization of settings, ensuring precise control over the size, weight, and dough-to-filling ratio. This makes the P160 Date Ball Encrusting Machine ideal for commercial operations where uniformity and speed are critical.

Superior Customization and Production Flexibility

With the ability to switch between multiple molds and settings, the P160 allows users to create various snack types with ease. The included Small Ball Rounding Machine P110-1 ensures each ball is perfectly round, while the Coconut Date Ball Covering Machine P110-2 can apply a wide range of coatings like coconut flakes or cocoa powder. The machine is built to be user-friendly, even for operators with minimal experience, making it an excellent choice for both small-scale and industrial-level food production.

Enhanced Efficiency and Easy Operation

Thanks to its dual hoppers and spiral screw extruder, the P160 Date Ball Making Line achieves precise extrusion, shaping, and filling with minimal waste. Whether producing energy balls, protein balls, or date balls, this machine operates efficiently while maintaining a high output rate. Its modular design also simplifies cleaning and maintenance, reducing downtime and maximizing productivity.

Product Features

Fully Automatic System: Ensures a high production rate with minimal manual labor.

Two Hopper System: Allows for both filled and unfilled products, offering flexibility in production.

Spiral Screw Extruder: Delivers smooth and consistent dough extrusion, even with dense mixtures.

Touch Screen Panel: Easy-to-use interface for controlling production parameters.

Versatile Coating Options: Supports coatings like coconut flakes, nuts, seeds, and more.

the roller machine is the secondary machine connected after the protein ball extrusion machine, the protien ball rolling machine adopts stainless steel structure and aluminum rolling wheel to roll each ball with adjustable speed and anti-sticky treatment. The ball diameter rolling range is 10mm to 50mm.

The coconut flake coating machine also adpots stainless steel structure and aluminum rotating drum, it can coat coconut flakes, smashed nuts, powder, seeds, and so on.

Chocolate date Ball Making Machine Specifications:

| Model | P160

|

| Capacity | 60-100 PCS/MIN |

| Product Diameter | 10-50MM |

Power

| 2.55KW |

Voltage

| 220V/50HZ |

| Weight | 380KG |

| Dimension | 2400*860*1300MM |

Advantages

PLC Touch Screen: Simple and intuitive operation, capable of saving up to 99 production modes.

Multipurpose Encrusting Machine: Supports a wide range of products, including twist designs and smoother dough surfaces.

Push-Back Device: Enhances food shaping and ensures more stable conveyance.

Additional Hopper Option: The P160 can accommodate a third hopper, enabling the production of double-filled or double-colored cookies and maamoul.

Adjustable Dough and Filling Ratios: Easily modify the ratio of dough to filling, as well as the size and weight of the final product.

Multifunctional Design: Capable of producing a variety of filled products by changing the shutter/mold.

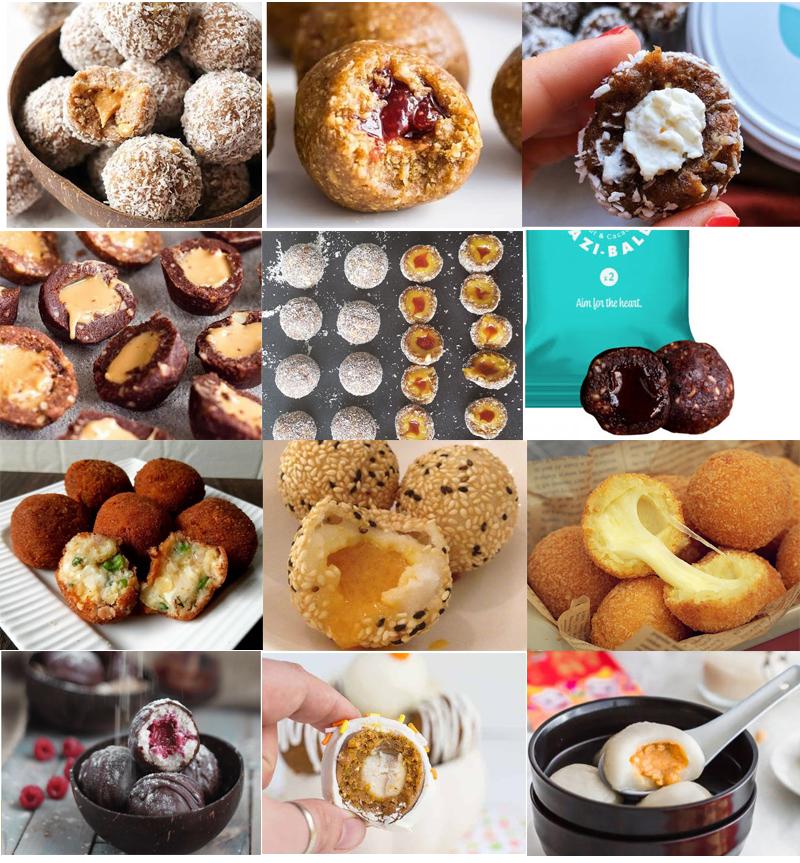

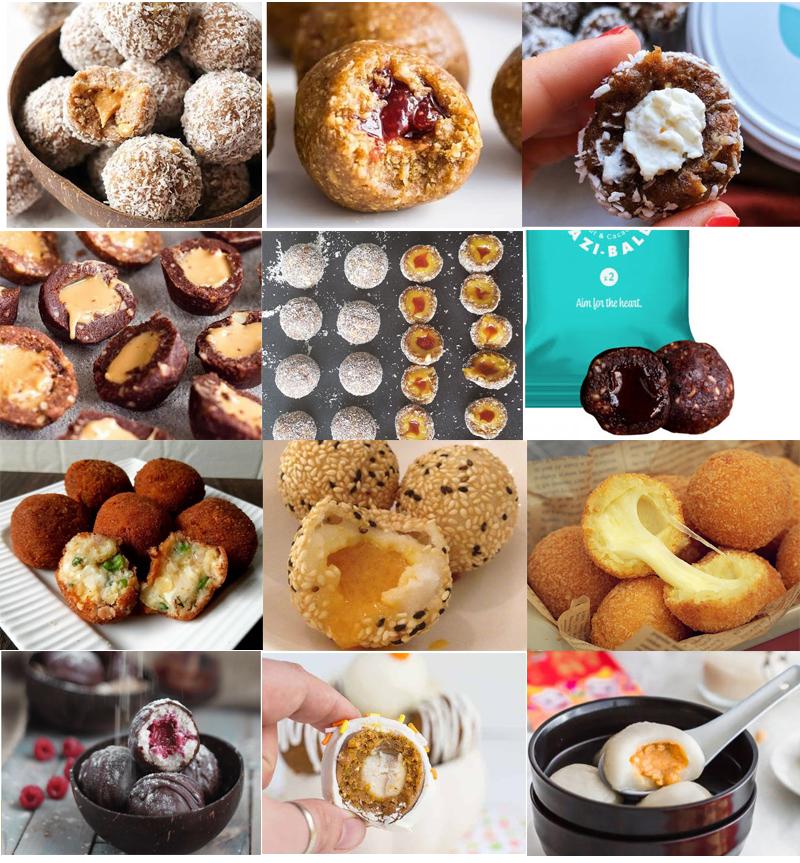

Applications

The P160 Date Ball Making Line is perfect for producing:

Energy balls

Protein balls

Date balls

Coconut balls

Bounty balls

Chocolate truffles

Sesame balls

This machine is suitable for commercial bakeries, confectioneries, and businesses focused on health snacks.

P160 encrutsting machine application :

P160 produce stuffed food ball :

P160 Produce protein ball energy ball with ball rounder and coconut coating machine video :

Add chocolate enrober to cover chocolate on date ball

Peanut jam filled date ball production line video:

How to Maintain

Clean the hoppers and extruders regularly to prevent dough buildup.

Lubricate the moving parts according to the manufacturer's instructions.

Check the calibration frequently to ensure the weight and size of the balls remain consistent.

Why Choose the P160 Date Ball Making Line

Precision: Ensures consistent product quality with minimal deviation.

Versatility: Can produce a wide variety of filled and unfilled balls.

Efficiency: Capable of large-scale production with minimal labor requirements.

User-Friendly Interface: Intuitive touch screen controls make operation simple for any user.

FAQs

Q: Can the machine handle dense mixtures like protein or date paste?

Q: How easy is it to clean the machine?

Q: What type of coatings can be applied with this machine?

A: The Coconut Date Ball Covering Machine can apply coatings like coconut flakes, nuts, seeds, and more.

The P160 Date Ball Making Line from Papa Food Machine offers unparalleled precision and efficiency, making it an essential tool for businesses looking to automate their energy ball production. Whether you're producing date balls, protein balls, or coconut-covered treats, this machine guarantees high-quality results with minimal effort.