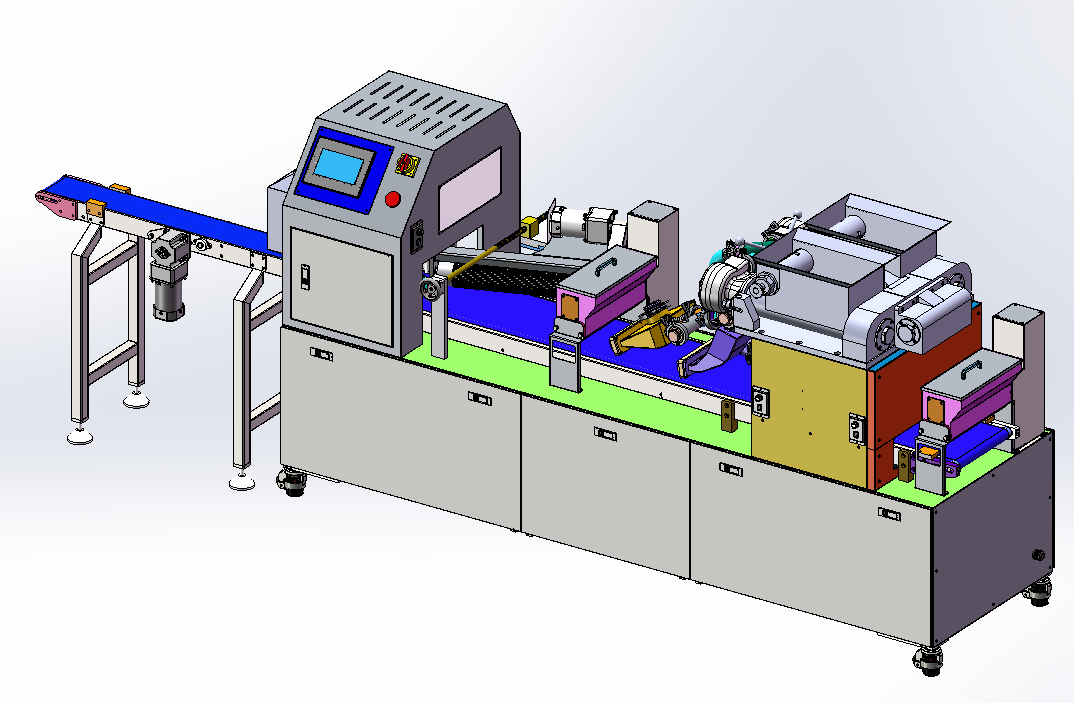

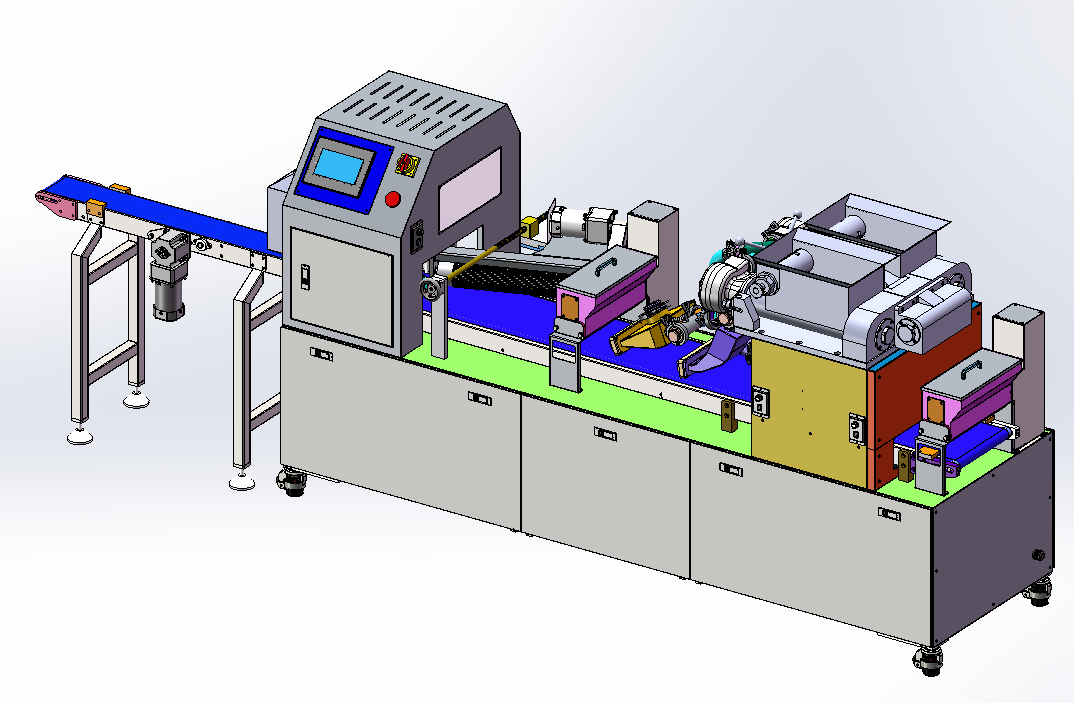

Product Description

The PM101B Automatic Encrusting Machine is a cutting-edge solution for producing both single-crust and stuffed products in the food industry. Featuring a double hopper and double screw direct push type feeding, it guarantees minimal material damage while ensuring a smooth discharge. With adjustable powder spreaders and a brake clutch motor mechanism, this machine operates at up to 120 cuts per minute, producing multi-layered items with a maximum peel width of 25 centimeters. Designed for easy cleaning and disassembly, it embodies efficiency and convenience.

Advanced Feeding System

The PM101B Automatic Encrusting Machine utilizes a double hopper and double screw direct push type feeding mechanism, minimizing material damage during processing. This advanced system allows for even pressure distribution, ensuring that the ingredients remain intact and are discharged smoothly without size differences. The machine can produce both single-crust and stuffed products, making it versatile for various applications in the food industry.

Precision Cutting and Layering

Equipped with a brake clutch motor mechanism, this machine achieves cutting speeds of up to 120 times per minute, facilitating efficient production. The adjustable powder spreaders on the conveyor belt, noodle pin, and knife edge allow operators to customize powder output to prevent product sticking. The machine can handle a maximum peel width of 25 centimeters, enabling the production of multi-layered items that are visually appealing and deliver excellent taste.

Easy Maintenance and Operation

The PM101B is designed with user convenience in mind. Its large-diameter quick-connect interface facilitates easy disassembly and cleaning, ensuring hygiene standards are met. The machine's robust construction using high-quality materials enhances its durability, making it a reliable choice for continuous operation in food production environments.

As the first manufacturer to develop protein bar extruders, Papa Food Machine offers this innovative encrusting machine, reinforcing its commitment to high-quality food processing machinery. By investing in the PM101B Automatic Encrusting Machine, businesses can streamline their operations, improve production efficiency, and deliver consistent, high-quality products that meet consumer demands.

Product Features

Double hopper for versatile feeding

Double screw direct push type feeding for minimal material damage

Capable of producing single-crust and stuffed products

High-speed cutting at 120 times per minute

Adjustable powder spreaders for customization

Easy disassembly and cleaning features

Constructed with durable materials for longevity

Maximum peel width of 25 centimeters

Specification:

Type: PM101B

Capacity: 10-100 pieces/minute

Product weight: 10-150 grams

Power: 1.5kw

Voltage: 220v/50hz

Overall dimensions: 3550*710*1282mm

Overall dimensions: 3550*710*1282mm

Weight: 500KG

Weight: 500KG

The mochi roll dough need use mochi dough steamer .

Please contact this email to learn more in details : info@papamachine.com Diana Ding

How to Maintain

Regularly clean the machine after use to prevent residue build-up.

Check and adjust the powder spreaders for optimal performance.

Inspect the double hoppers and conveyor belt for wear and tear.

Ensure all electronic components are functioning correctly by performing routine checks.

FAQs

Q: What types of products can the PM101B machine produce?

A: It can produce both single-crust and stuffed products, including various pastries and confections.

Q: How easy is it to clean the machine?

A: The machine features easy disassembly and a large-diameter quick-connect interface for efficient cleaning.

Q: Can the machine handle different types of fillings?

A: Yes, the PM101B is designed to accommodate a wide range of fillings, including sweet and savory options.

Overall dimensions: 3550*710*1282mm

Overall dimensions: 3550*710*1282mm