Description

The PU600 Ultrasonic Cutting Machine is a state-of-the-art, fully automatic food cutting solution designed to enhance production efficiency. Featuring a multi-axis standard control system, this machine offers precision positioning and cutting capabilities tailored to your specific requirements. The automated operation simplifies the cutting process, making it ideal for various food production environments.

Specification :

Model | PU600 |

Dimensions | L1745*W1480*H1200mm |

Weight | Net Wt. 350KGS, Gross Wt.440KGS |

Voltage | 220V/380v |

Rated power | 8000W |

Frequency | 50Hz-60Hz |

Cutting speed | 35-60cuts/minute |

Number of blades | 2 group blades |

Blade materials | Titanium Alloy |

Blade size | 305mm*2 |

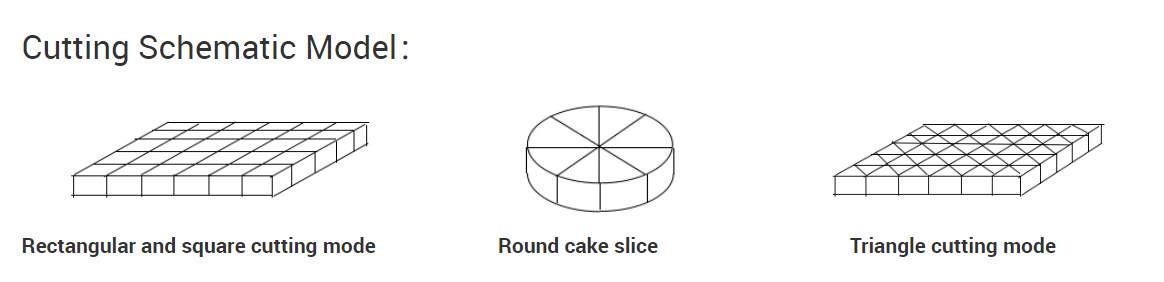

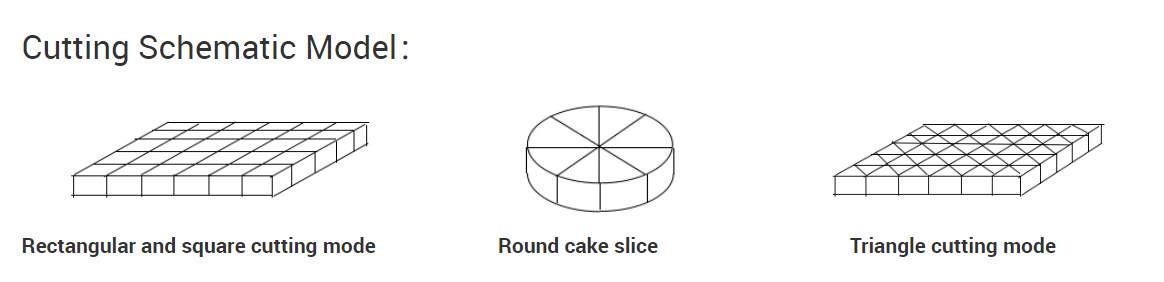

Cut type | Square, rectangular, cake slice, triangle shape, |

Maximum cutting size | 600mmx400mm,food cutting height up to 80mm, blade up height:100mm. food height exceeds 80mm can be customized |

Material of machine frame | Stainless Steel |

Self cleaning | Yes need water and |

Safety protection system | Infrared inspection, frequency ultrasonic scan and fault indicator lamp |

Control System | Four-axis Control System |

Cutting knife control system | Servo motor |

Machine mobility | Casters |

Certification | CE |

Key Features

· High-Frequency Wave Vibration: Utilizing ultrasonic technology, the cutting system operates at 2000 vibrations per second. This high-frequency vibration creates a friction-reducing surface between the blade and food, significantly minimizing wear and tear on the blade and reducing annual maintenance costs.

· Streamlined Production: The innovative design of the ultrasonic cutting system minimizes downtime associated with cleaning traditional cutting blades. This not only optimizes the production process but also reduces waste, contributing to a more sustainable operation.

· Versatile Cutting Options: The PU600 is capable of precise cuts into various shapes, including sheets, rectangles, triangles, and equidistant circles. Whether you're working with multi-layer cakes, frozen products, or cream-based items, this machine can handle it all.

· Multi-Layer Cake Cutting: Designed to maintain distinct colors between layers, the ultrasonic cutting machine ensures that your multi-layer cakes look as good as they taste.

· Customization: Our ultrasonic cutting machine can be customized to meet the unique requirements of your business. Whether you need specific dimensions or additional features, we can tailor the machine to suit your needs.

Additional Benefits

· No Slags or Sticking: The ultrasonic knife cutting technology ensures clean cuts without residues, enhancing the overall quality of your products.

· Wide Cutting Field: Beyond cakes, the PU600 can effectively cut various food items, making it a versatile addition to any kitchen or production facility.

Product shape

square / triangle / piece / diamond / circle

FAQs

1. What types of food can the PU600 Ultrasonic Cutting Machine process?

The PU600 is versatile and can cut a range of food items, including multi-layer cakes, frozen products, and cream-based foods.

2. How does ultrasonic cutting differ from traditional cutting methods?

Ultrasonic cutting uses high-frequency vibrations to create a friction-reducing effect, resulting in cleaner cuts with less wear on the blades compared to traditional methods.

3. Is the PU600 easy to operate?

Yes, the PU600 features a fully automatic operation with a user-friendly interface, making it easy to position and cut food according to your requirements.

4. Can the machine be customized for specific production needs?

Absolutely! The PU600 can be tailored to meet your unique cutting requirements, including custom dimensions and additional features.

5. What maintenance is required for the PU600 Ultrasonic Cutting Machine?

The ultrasonic cutting technology minimizes blade wear and reduces maintenance needs, but regular cleaning and occasional inspections are recommended to ensure optimal performance.