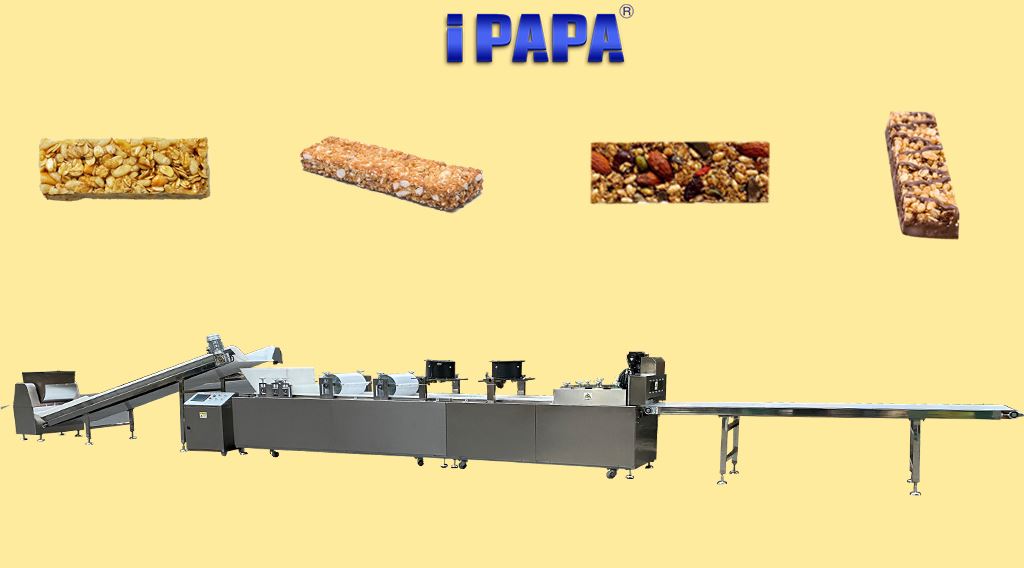

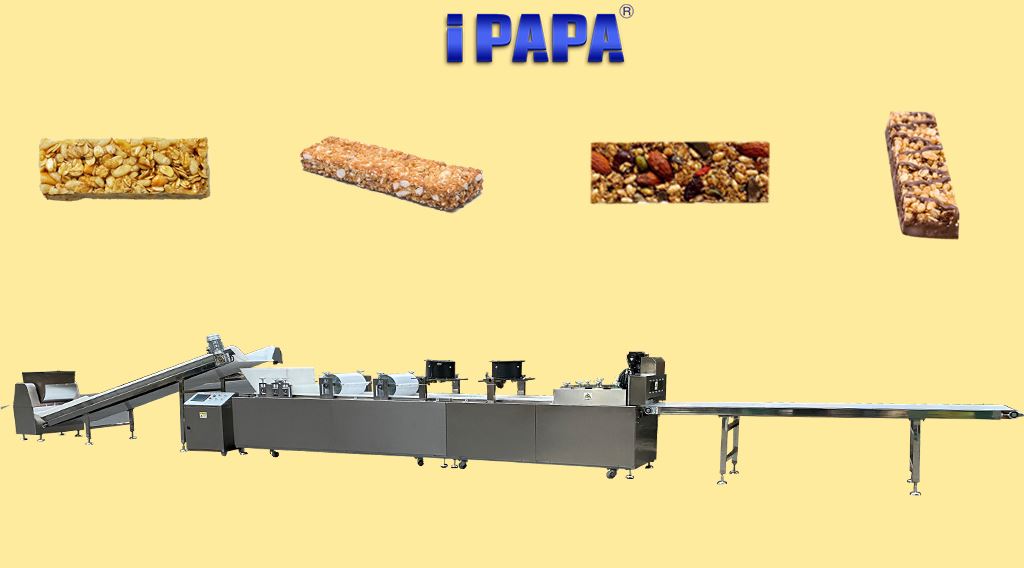

P401 Automatic cutting and forming prouction line for cereal bar granoula bar rice bar mulise bar ,peanut bar and so on

Slab line forming machine is also called cereal bar making machine ,granola bar production line.

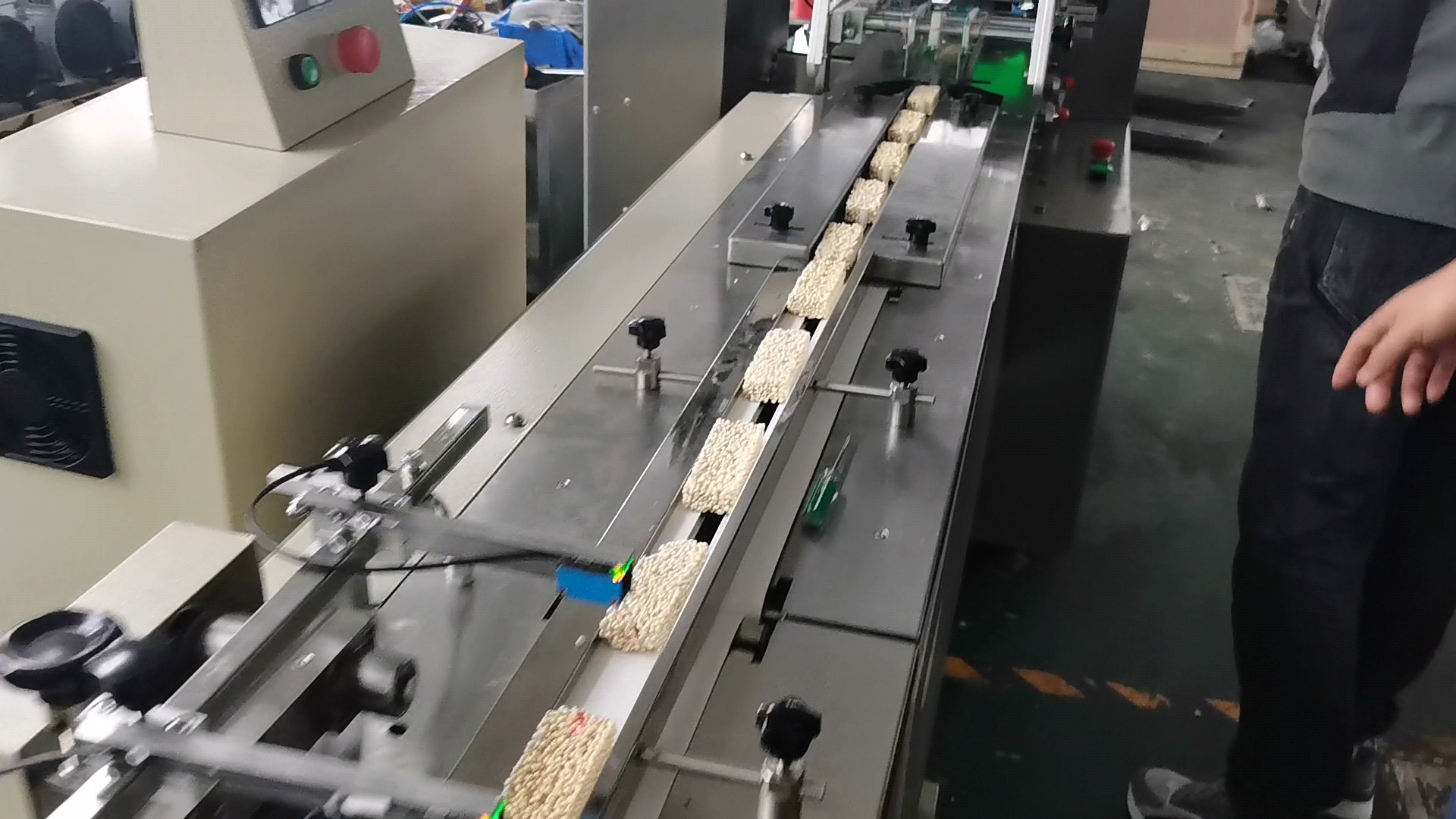

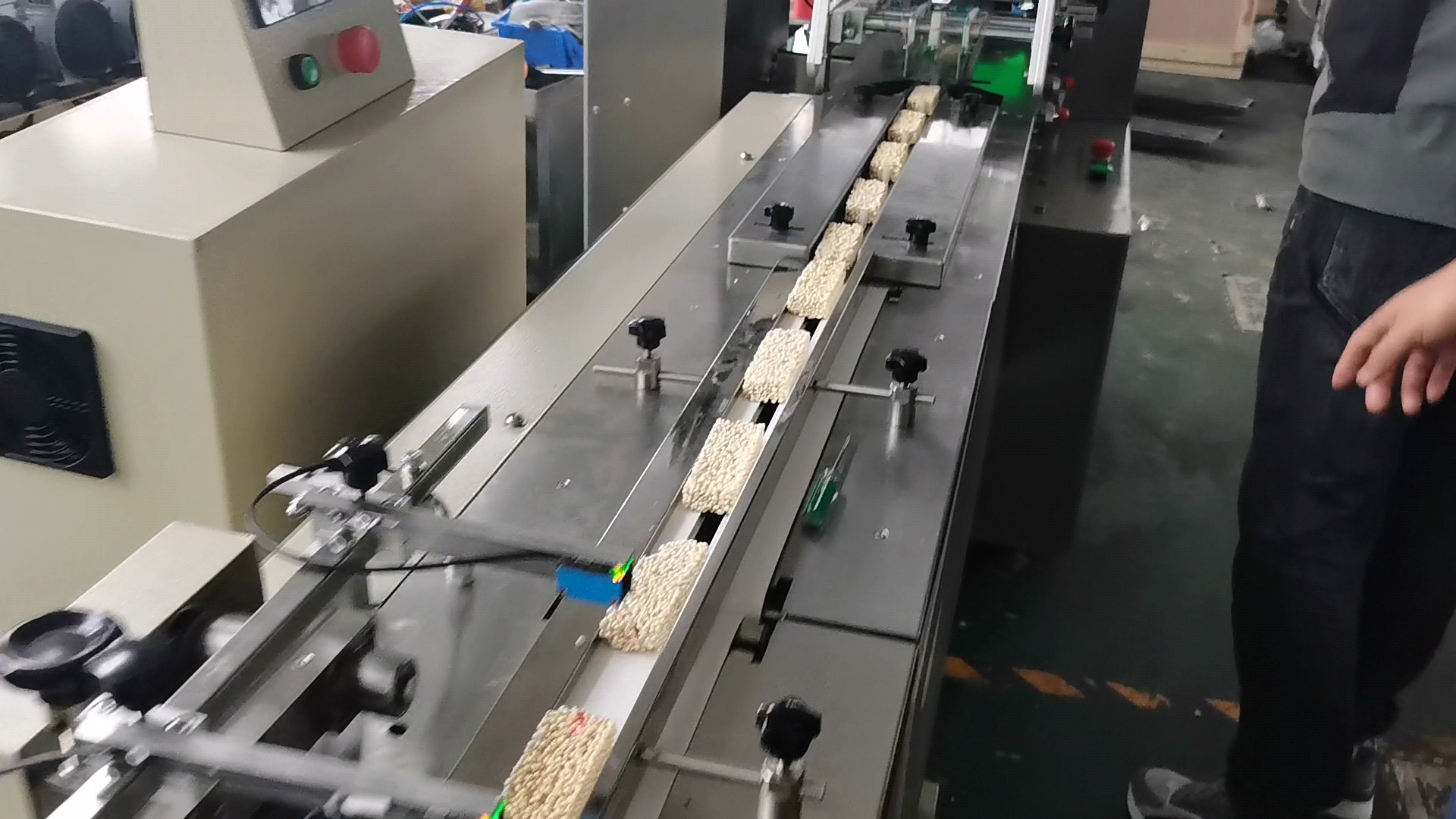

cereal bar, rice bar, and peanut bar making line is a specialized production line for manufacturing these types of snack bars in a commercial or industrial setting. This line typically includes machinery and equipment for sugar cooking, ingredient mixing, cooking or heating, forming into bar shapes use bar forming and cutting machine, cooling, and automatic packaging. The production line may also include specific components for adding coatings, fillings, or toppings to the bars. Key components of the production line may include mixers, cookers, extruders or forming machines, cooling conveyors, and wrapping or packaging equipment. These machines are designed to efficiently and consistently produce a high volume of snack bars while maintaining quality and consistency.

Finished products: Cereal bar, peanut bar, muesli bar, energy bar,rice bar , Mihua Tang, corn cakes, black rice cakes and a variety of granular products, forming cut.

The forming and cutting of rice candy, peanut crisp, black rice crisp,etc

Main properties and structure characteristics:

The machine adopts microcomputer control, automatic correct dimensions

Automatic feeding, leveling, chop Recruitment, high yield

Transmission system is concise, clear

Hopper&roller: Teflon coated

Technical parameters:

Capacity: 1-5 m/min; 100-300 kg/h

Voltage: 380v/50Hz

Power: 5 kw

Weight: 1200 kg

Dimension: forming 4500*1400*1300 mm

Cooling conveyor: 3000*800*750 mm

Model | P401 | P402 | P403 |

Capacity | 150-250KG | 250-350KG | 300-800KG |

Power | 5KW | 5.5KW | 10KW |

Voltage | 380V 3 phase | 380V 3 phase | 380V 3 phase |

Dimension | 4800*920*1200mm | 6000*920*1200mm | 12000x1400x1300mm |

Weight | 1200KG | 1500KG | 1800KG |

Cooling type | Fan cooling | Fan cooling | Refrigerator |

Electric syrup cooker

Model: 200

Capacity: 200L

Power: (mixing motor) 1.1KW

Source: electric 18KW

Weight: 230KG

Dimension: 1100*1300*1600 mm

Temperature control material mixer

Model: 40

Power: main machine: 1.1KW

Heating: 3KW

Capacity: 65L

Weight: 118KG

Dimension: 670*620*1340mm

Structure: The machine consists of: rack(carbon steel spray paint, covered with stainless steel),temperature heating pot body (stainless steel, heating pipe panel, main boday, inner wall PTFE protecting material), stirrer (all PTFE material), electric control box.

Material conveyor

Power: 0.55 KW

Dimension: 3000*700*1300 mm

Material: food grade, stainless steel

Application: sugar mixed material conveying

P401 Automatic cutting and forming

Flow wrapping machine for cereal bar peanut bar ,rice bar packing

Packing speed: 35-220bags/min

Bag size: L: 65-200MM; W: 30-90MM; H: 5-30mm

Film width: 65-220mm

Packing materials: opp/cpp,pt,pe,kop/cpp,alu-foil

Dimension: 4000x850x1600mm

Heating Power: 2.4kw

Motor power: 0.2+0.4kw

Total power: 3kw

Weight: 550kg