Puffed Pastry Production Line

Equipment Information

The Puffed Pastry Production Line is designed to optimize the production of various baked goods, including durian cakes. This advanced line consists of the P868 three-roller main machine, a filling machine, a kneading forming machine, and a plate arrangement machine.

The production process begins by guiding pre-made dough through a conveyor belt into the three-roller main machine for division. The dough then undergoes a series of three progressive thinning stages involving pressing, shaping, thinning, filling, stuffing, and rolling. After closure by the kneading machine, the dough is grouped and automatically arranged into baking pans by the tray arranging machine. This meticulous method preserves the gluten structure, ensuring an artisanal flavor in the final product.

For enhanced functionality, customers can select optional front-end equipment, including a dough mixer, dough press, and pastry machine.

Features

Three-Step Dough Pressing: Enhances dough shine and ensures consistent quality.

Progressive Thinning: Thickness adjustment devices on each dough pressing wheel allow for precise control over dough thickness and product weight.

Electric Eye Regulation: Sensors regulate dough speed between pressing wheels and rolling devices, preventing breakage or blockages due to speed discrepancies.

Roll-Up Molding Technique: This innovative technique preserves dough integrity and enhances the artisanal flavor of the final product.

Independent Flower Kneading Machine: Equipped with flower-shaped cutters, this feature enables the production of various items such as flower buns, light buns, shortbread, bread, and burgers.

Convertible Pinching and Chopping Machines: These machines can produce cut products, including bread and steamed buns.

Adjustable Production Parameters: Easily modify product size, speed, and skin-to-stuff ratio to meet specific production needs.

Applications

The production line is suitable for a wide range of products including shortbread cakes, wife cakes, Soviet-style moon cakes, egg yolk cakes, Taiwan Q cakes, Snow Mei Niang mung bean cakes, fresh meat cakes, durian cakes, mung bean cakes, beef tongue cakes, liquid cakes, custard liquid cakes, black gold cakes, purple sweet potato pancakes, pop cakes, chestnut puffs, butter red bean buns, hot dog buns, hamburgers, French bread, toast, steamed buns, meat buns, vegetable buns, rabbit buns, red bean paste buns, silver rolls, birthday peaches, and more.

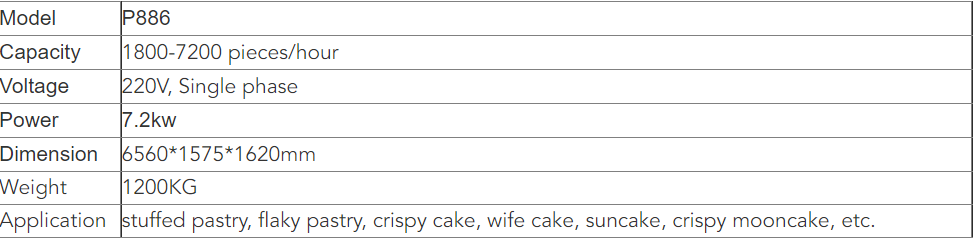

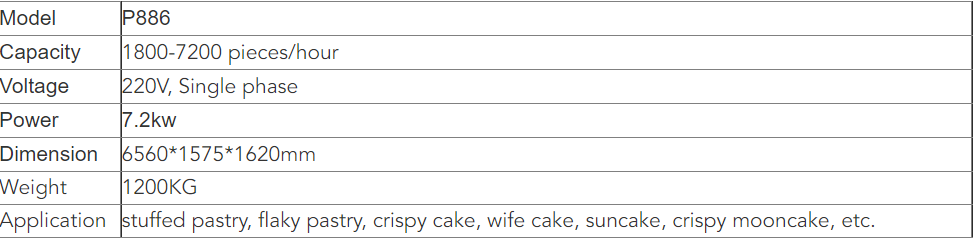

Specification

If you wanna produce double filling cake or foods , the filling feeding machine can be changed into Three hopper encrusting machine .

FAQs

1. What types of dough can be processed using the Puffed Pastry Production Line?

The production line is suitable for various dough types, including shortbread, fresh meat, and durian cake dough.

2. What is the production capacity of the Puffed Pastry Production Line?

The capacity depends on the specific settings and configurations but is designed for high efficiency, producing a large volume of baked goods.

3. Can I customize the product sizes and shapes?

Yes, the line features adjustable production parameters, allowing for customization of product size, speed, and skin-to-stuff ratio.

4. Is the equipment easy to maintain?

Yes, the machines are designed for ease of maintenance, with accessible parts for cleaning and servicing.

5. Can the line be expanded with additional equipment?

Absolutely! You can choose from additional front-end equipment such as dough mixers and pastry machines to enhance production capabilities.