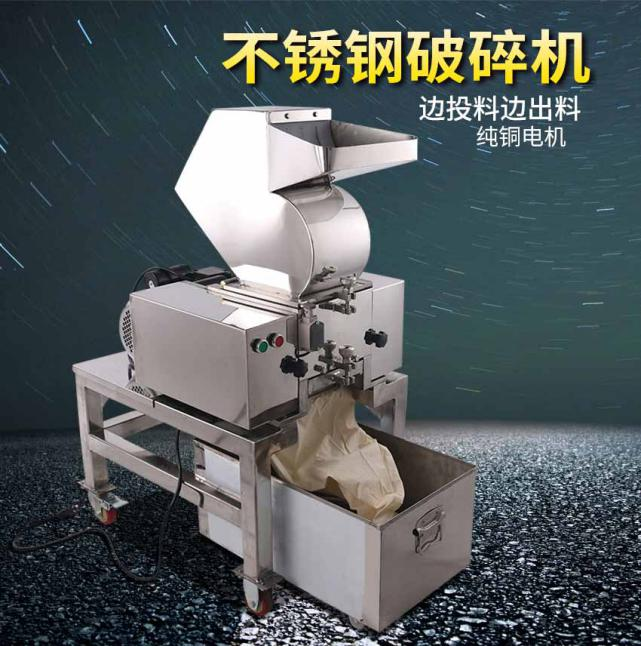

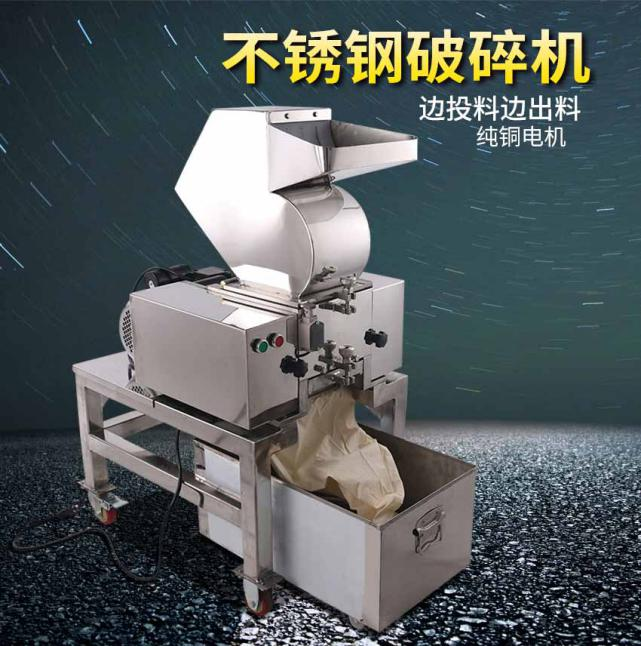

Automatic Nut Crushing Machine Overview

Shanghai Papa Industrial Co., Ltd. specializes in manufacturing a range of advanced automatic nut crushing machines. These machines incorporate cutting-edge technology and integrate advanced experiences from both domestic and international markets, ensuring exceptional performance and efficiency. Our newly designed equipment boasts numerous advantages, such as competitive pricing, appealing aesthetics, reduced noise, minimal vibration, low energy consumption, high-quality knife steel, extended durability, and ease of cleaning.

Stainless Steel Construction

The automatic nut crushing machine is made of stainless steel, featuring an attractive and robust appearance that meets GMP requirements. Stainless steel 304 can be customized according to customer specifications, enhancing its versatility and application.

Innovative Design

The feeding hopper, crushing chamber, and sieve mesh all adopt a separated design, facilitating easy installation and dismantling. The feeding inlet features a vertical curtain design made of advanced silica glue with a thickness of 5mm, effectively preventing material from flying out during operation.

Soundproofing Technology

The front and back walls of the crushing chamber are designed with double-layer soundproofing to significantly reduce noise levels. A protective casing is installed around the belt wheels for enhanced safety and reliability.

Safety Mechanisms

A stroke switch is installed between the upper layer and downward layer in the grinding cavity. If the hopper is opened due to feeding materials, the power will shut down automatically, ensuring operator safety. Additionally, an overheat protection device is integrated with the motor, along with a power interlock, to safeguard the entire system.

Durable Cutting Knives

The machine uses specially designed knives made from advanced steel, offering exceptional durability. The knife installation is flexible and adjustable, allowing for multiple sharpenings. This design ensures long-lasting performance and consistent cutting efficiency.

Efficient Material Handling

The fabrication workmanship is comprehensive, with key parts of the machine body and knife structure adopting whole-formed designs to ensure precision. The motive seat employs a stepped class and scissor-style design, effectively distributing shearing power for optimal performance.

Convenient Operation

With a reasonable structure, convenient operation, energy savings, and durability, the automatic nut crushing machine is practical and economical. It also features a seal-ring shaft design, ensuring long-lasting performance and reliable transmission. The knife shape is engineered for even particle distribution, and the knife seat undergoes thermal forming treatment for enhanced aesthetics.

Increased Capacity

Compared to traditional iron crushing machines, the dimensions of the stainless steel crushing machine's body shelf have increased by 15cm in height and 30cm in width. Consequently, the volume of the feeding hopper is more than double that of standard crushing machines.

Enhanced Outlet Design

The outlet of the stainless steel crushing machine features a unique and extended design, allowing connection to external cloth bags. This design maximizes the reduction of powder dust during material crushing. Traditional crushing machines often have limited hopper capacity, requiring frequent shutdowns for hopper replacements, leading to inefficiencies. In contrast, our design reduces labor waste and enhances production efficiency.

Mobility Features

Rubber feet with braking devices are installed on various models, including the 180, 250, and 400, allowing for convenient mobility.

Specification for nut crushing machine :

Specifications |

Model | PE-180S | PE-250S | PE-400S | PE-600S | PE-800S |

Voltage (V) | 220V/380V | 380V | 380V | 380V | 380V |

Power supply (KW) | 2.2 | 4 | 7.5 | 15 | 22 |

Motive knives (piece) | 9 | 6 | 12 | 18 | 24 |

Fixed knives (piece) | 2 | 2 | 2 | 2 | 4 |

Crushing capability (kg/h) | 80~150 | 120~280 | 200~400 | 300~500 | 500~1000 |

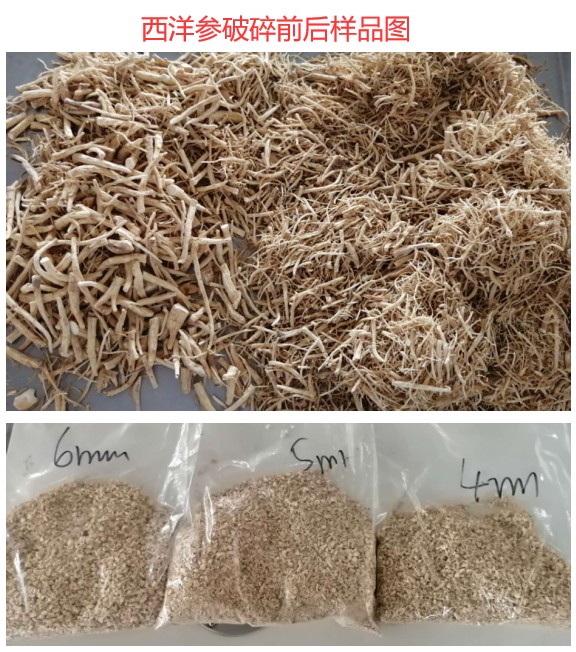

Aperture of sieve mesh (mm) | Standard aperture is 6mm and 8mm,10/12/14/16/18/20/30mm can also be customized.The aperture below 6mm can’t be customized. |

Velocity of spindle rotation ( r/min ) | 720 | 690 | 600 | 490 | 450 |

Feeding caliber (mm) | 190×138 | 245×165 | 405×208 | 605×213 | 805×228 |

Weight(kg) | 140 | 190 | 355 | 580 | 980 |

Overall Dimension (mm) | 880×550×1125 | 1000×645×1180 | 1125×845×1135 | 1380×1050×1420 | 1570×1290×1590 |

Scope of Application

The automatic nut crushing machine is suitable for crushing a variety of materials, including:

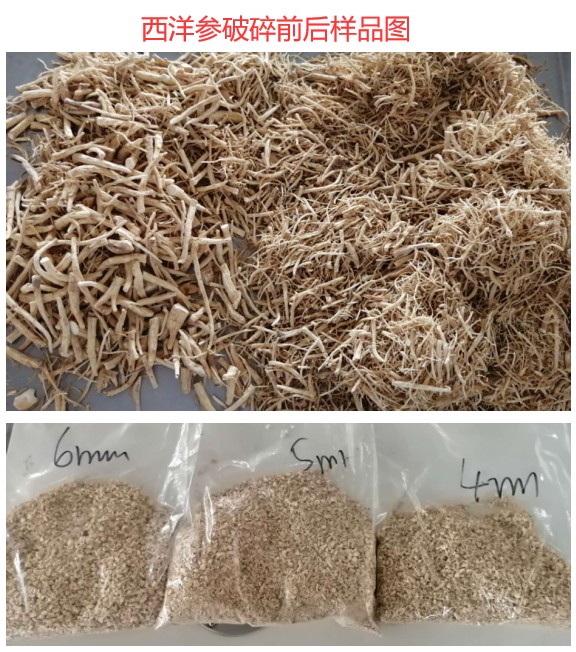

Traditional Chinese Medicine Herbs: Efficiently processes medicinal plants.

Nuts: Handles a range of nuts such as peanuts, almonds, and cashews.

Chemical Raw Materials: Capable of crushing various low-rigidity chemicals.

Plastic Products: Suitable for crushing polystyrene, polypropylene, and other soft plastics.

The machine can also crush various abandoned plastic products, including blown molding films, thin boards, and mineral water bottles.

Workable Material

Nuts: Includes peanuts, almonds, cashews, etc.

Traditional Chinese Medicine Herbs

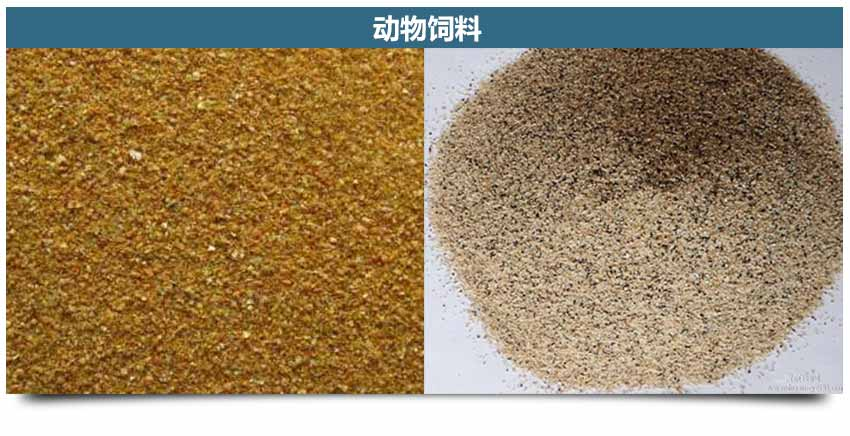

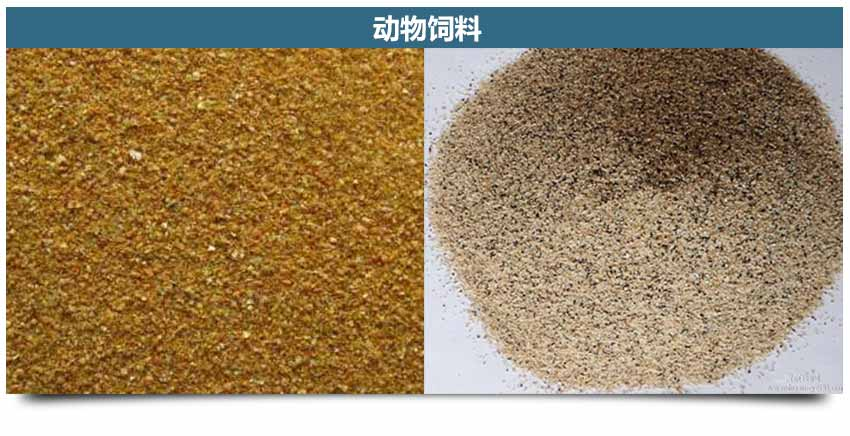

Animal Feeding Materials

Chemical Raw Materials

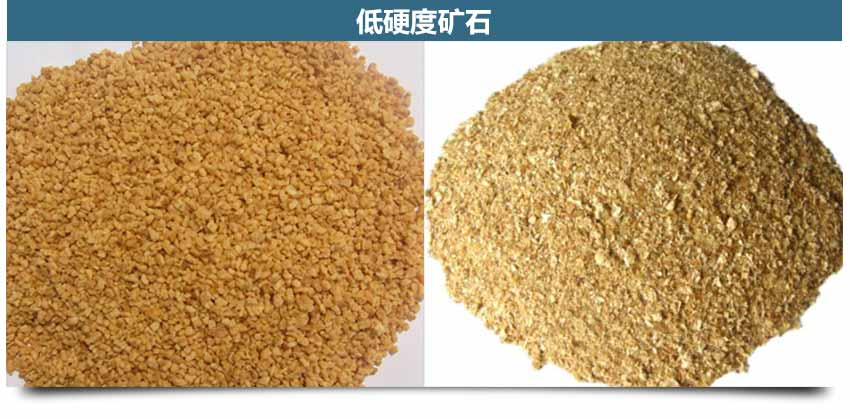

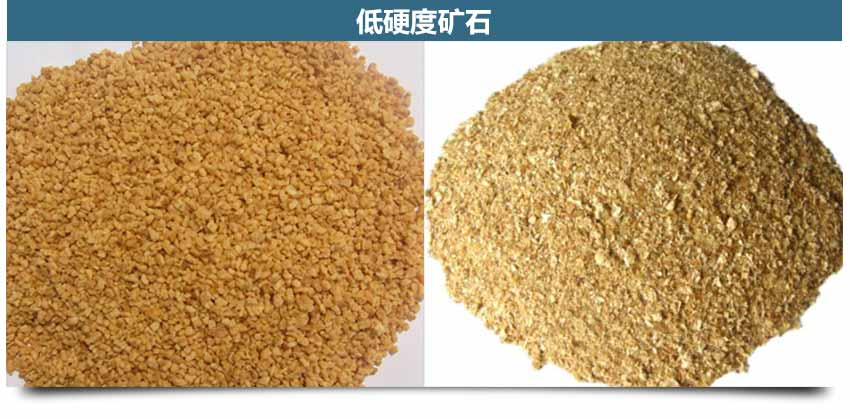

Low Rigidity Ores

The outlet of series of stainless steel crushing machine adopts unique and stretching outside design.This kind of outlet can be connected to the exterior cloth bag,whose advantages as follows:

1. Maximize to reduce powder dust flying everywhere during the period of crushing materials.

2. The volume of feeding hopper of traditional crushing machine is extremely limited.When the hopper is full,please shut down the power supply and then replace another hopper to start working again.Hence,this kind of design of traditional crushing machine will be a waste of human labor and low efficiency.Compared to this kind of traditional crushing machine,design of stainless steel crushing machine can reduce a lot of waste of human labor and enhance production efficiency.( Remarks:The traditional crushing machine has no skirt-edge stretching outside design,in addition,the outlet with the distance to the ground is low,it hardly can’t connect cloth bag. )

3. Rubber feet wheels with braking device are installed on series of stainless steel crushing machines such as model 180,250,400 to be moved conveniently.

Traditional Chinese Medicine Herbs

Plaster

Feeding materials for animals

Chemical Raw Materials

Features of Automatic Nut Crushing Machine

When utilized in industries like food processing, pharmaceuticals, animal feed, and scientific research, our automatic nut crushing machine overcomes the challenges of handling viscous, rigid, and soft materials. This stainless steel crushing machine is expertly designed to crush various materials effectively.

Main Usage

The automatic nut crushing machine excels in crushing materials that are difficult to process, such as those with rigidity and fiber, in food, pharmaceutical, and chemical industries. It is also suitable for crushing wood, fresh bones, and plastics. Additionally, it can serve as the first stage in the process before producing ultra-fine powders.

However, it is important to note that the machine has limitations regarding its operational principles and knife materials. It is forbidden to crush hard materials such as metals, high-rigidity ores, and high-density wood.

Crusher Machine Working Principle

The automatic nut crushing machine consists of five primary components: the machine shelf, feeding hopper, crushing cavity, sieve mesh shelf, and connecting hopper. Its advantages include simple construction, convenient washing, low noise, and effective operation. When in use, materials enter the crushing cavity from the feeding hopper. The crushing effect is achieved through the collision and shearing of rotating and fixed knives, allowing for precise control over particle size through adjustments in knife distance and sieve mesh selection.